Suction Blowing Systems

MultiEvacuator

A combined blower and cyclone designed for high capacity suction conveying

Kongskilde’s MultiEvacuator offers a highly efficient, integrated suction and conveying solution, perfect for handling a variety of granular materials in industrial settings. The unit is soundproofed for quiet operation, making it ideal for noise-sensitive environments.

By combining a high-pressure centrifugal blower with a cyclone separation unit, our evacuator ensures that materials are transported safely and efficiently without passing through the rotating blower rotor.

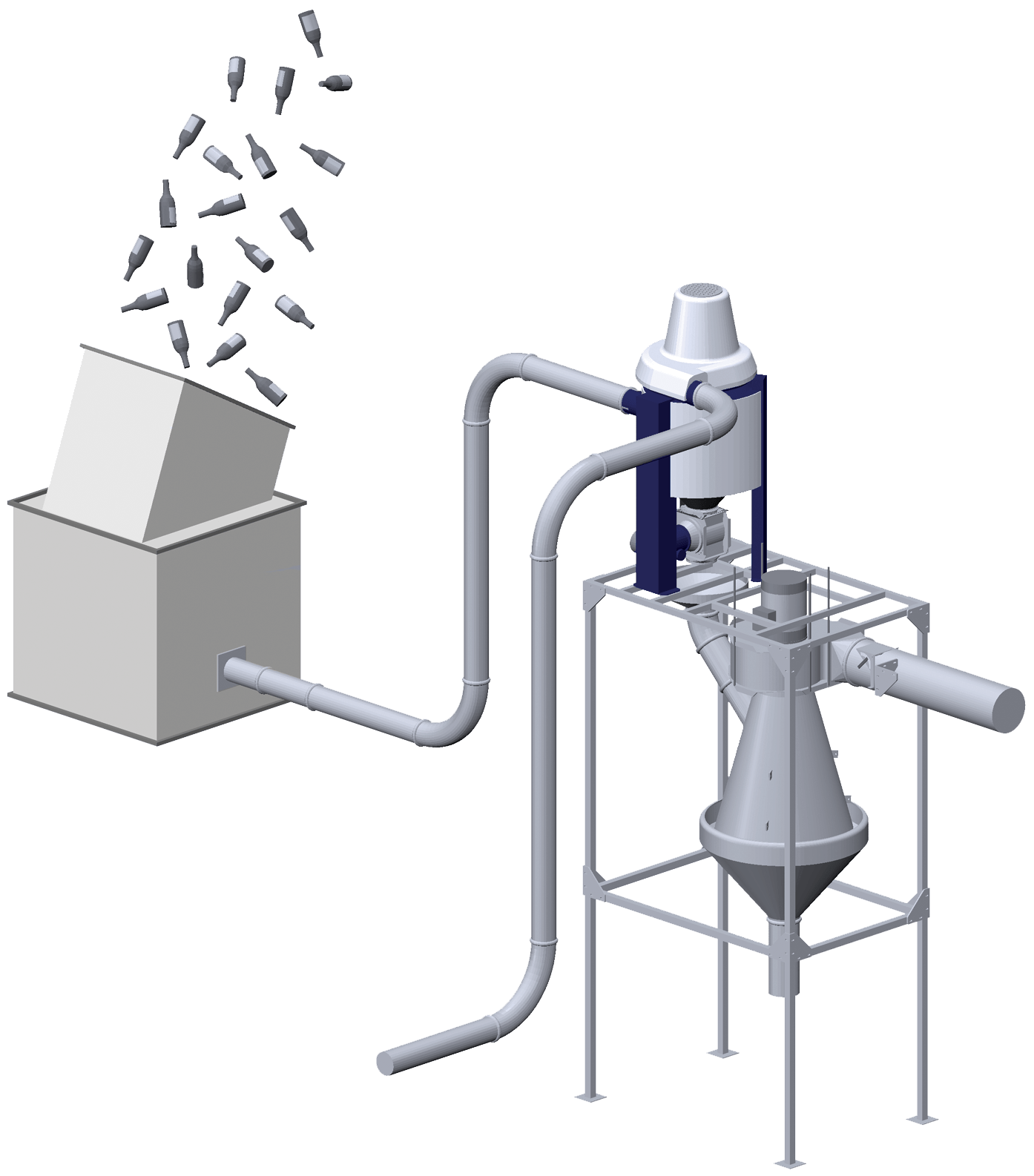

How the MultiEvacuator Works

The MultiEvacuator uses a powerful blower to create a vacuum, effectively picking up materials from one point and discharging them at another through a sophisticated cyclone and rotary valve system. This design prevents the materials from coming into contact with the blower rotor, ensuring a smooth and continuous flow.

Benefits of Using Kongskilde’s MultiEvacuator

- High Efficiency: Designed for high-capacity suction conveying, perfect for rapid and extensive material handling.

- Versatile Applications: Can handle everything from virgin material to regrind, ensuring flexibility across various industrial uses.

- Easy Maintenance: Features an accessible design with a top part that can be opened for straightforward cleaning and filter changes.

- Enhanced Safety: The cyclone separation unit prevents material wear on the blower, extending the lifespan of the system.

- Uniform Feeding: A MultiEvacuator solution ensures a more uniform material feeding rate.

- High Capacity: Depending on distance and material, conveying systems with capacities up to 7,000 kgs/hr (15000 lbs/hr) can be achieved.

- Quiet Operation: Equipped with a soundproof cabinet that minimizes noise levels, creating a more comfortable and compliant working environment.

Downloads

Download manuals, data sheets, and spare parts lists for the MultiEvacuator.

MultiEvacuator Model Comparison

Compare available MultiEvacuator models. Visit the downloads section for more information on specific models.

| MultiEvacuator 120 | MultiEvacuator 140 | MultiEvacuator 175 | |

|---|---|---|---|

| Motor (kW) | 1.5 | 3 | 5.5 |

| Rpm (50 Hz) | 2900 | 2900 | 2900 |

| Nominal consumption (Amp.) 50 Hz, 400 V | 3.3 | 6.15 | 11.0 |

| Weight, kg | 135 | 144 | 172 |

Video

MultiEvacuator Applications

The MultiEvacuator excels in the plastic processing industry for efficiently transporting virgin materials and regrinds. It’s also ideal for manufacturing settings, ensuring continuous material supply to molding machines and extruders. Additionally, it supports recycling operations by effectively handling granular regrind materials for reuse.