The Challenge

Overcoming Waste Management and Air Quality Challenges

A manufacturing company in Poland was facing a range of issues in its waste management process that impacted efficiency, safety, and air quality. Key challenges included:

- Mixed Waste Increases Costs: Different types of cuttings were placed in a single container, complicating recycling and increasing waste management costs.

- Manual Transport Posed Safety Risks: Shredding perforated sheets and large fragments was difficult, and transporting them manually from punching machines posed a safety risk to employees.

- Dust Impacted Air Quality and Product Standards: Dust generated during shredding and transport degraded air quality in the production hall, affecting both work comfort and product quality.

- No Energy Optimization System: The company lacked a system to automatically adjust energy consumption based on machine load, resulting in higher operational costs and an increased risk of downtime.

The Facts

- Material: Solid white and coloured cardboard and corrugated cardboard.

- Capacity: 8,000 sheets/min.

- Thickness: Up to 4mm

- Sheet Size: 1020x720mm, 1060x750mm, and 1450x1000mm

- Transport Distance: 40 m

System Requirements

- Must be able to collect waste from die-cutting machines with speeds of up to 8,000 sheets/min.

- Must convey to separate containers for different types of waste

- Must reduce noise and dust in the production hall.

The Solution

To address the challenges, the company implemented a custom, fully integrated waste handling and air filtration system from Kongskilde designed to improve separation, safety, and energy efficiency across the production process.

- The system includes a series of MultiDicers connected to production machines, with an MTD blower transporting material through OK and FK piping to KS separators. The air is cleaned via an MMBF filter and returned to the production hall.

- The cuttings were divided into white and coloured waste. The machine operator decides where the waste goes.

- Manually transported containers were eliminated and whole sheets were shredded, with the shredded waste being extracted directly into press containers.

- Dust was also collected when extracting the waste. The dust-laden air was cleaned in a filter and returned to production.

- Transport to the destination from the machines was divided, and a single main fan was used, adjusting its power depending on the number of machines in operation.

The Advantages and Benefits

By implementing an automated waste handling and air filtration system, the company addressed its key operational challenges and achieved significant improvements across cost efficiency, workplace safety, and productivity. The following benefits highlight the impact of the solution:

- Lower Costs and Safer Operations: Automated waste sorting reduced waste management expenses and eliminated manual scrap handling, improving employee safety.

- Improved Air Quality: The system separates dust from waste and filters the air before returning it to the production hall, enhancing both comfort and work environment safety.

- Optimized Energy Use: Precise control of blower performance adjusts energy consumption based on machine load, minimizing energy waste and lowering operating costs.

- Increased Productivity: Automation removed the need for manual waste handling, allowing operators to concentrate on production tasks and boosting overall efficiency.

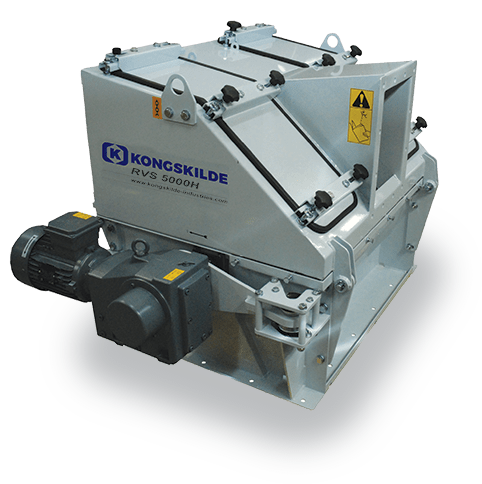

The Kongskilde MultiDicer efficiently cuts thick paperboard into small, uniform pieces for easy pneumatic transport, ideal for removing die-cut skeletons and improving waste handling in packaging production.

Shredding cardboard and corrugated cardboard reduces volume, simplifies storage, and improves handling. An enclosed pneumatic system keeps dust contained for a cleaner, safer workspace.

The KS rotating separator effectively separates small-sized waste and trim from the air stream in pneumatic conveying systems. This process not only cleans the air but also prevents the build-up of material, facilitating continuous production flow.

Download the full case study:

Featured Products

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.