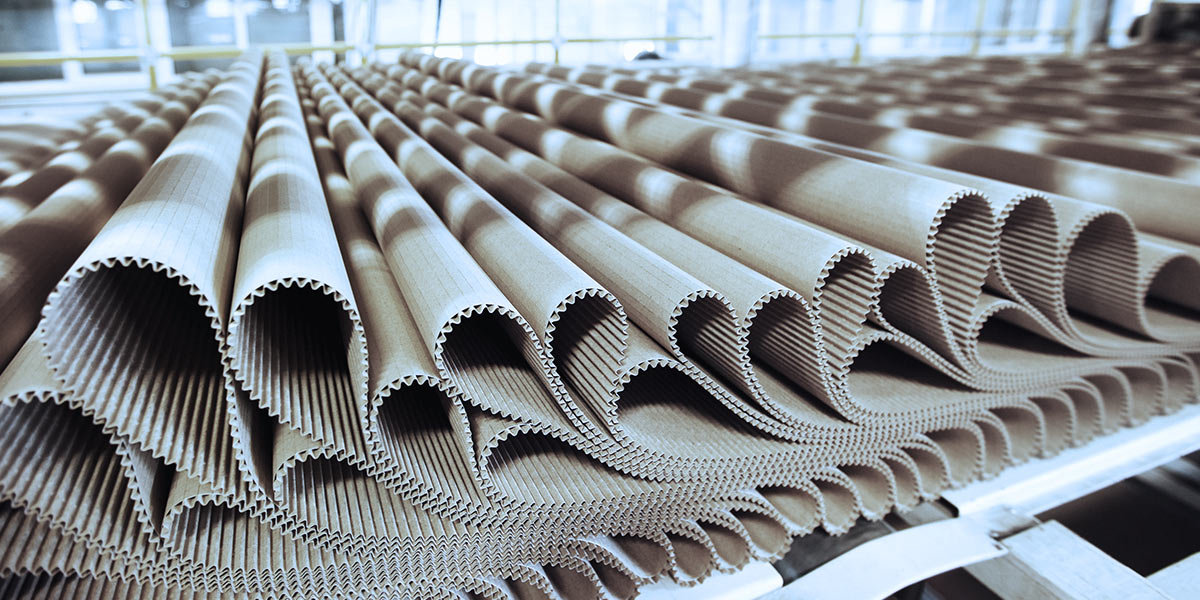

Paper trim removal systems designed to meet the demands of high-speed production lines across multiple industries

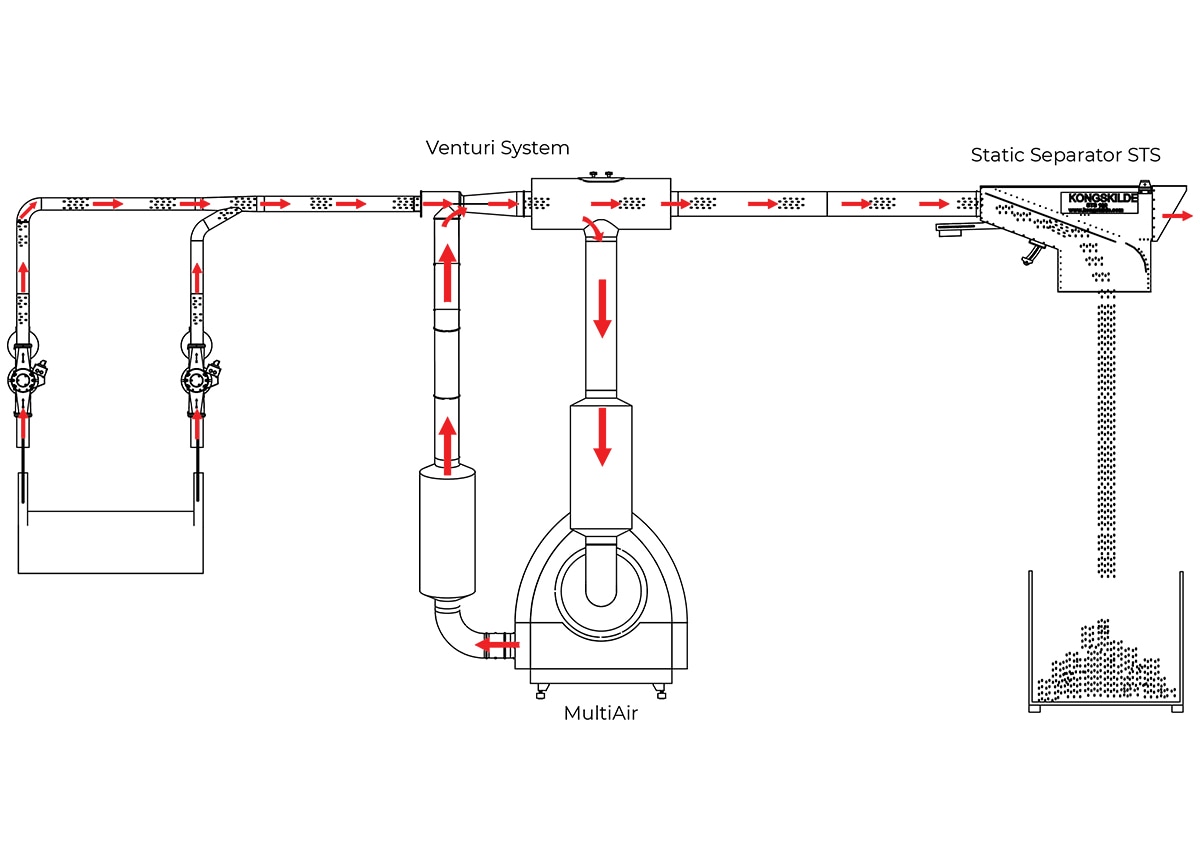

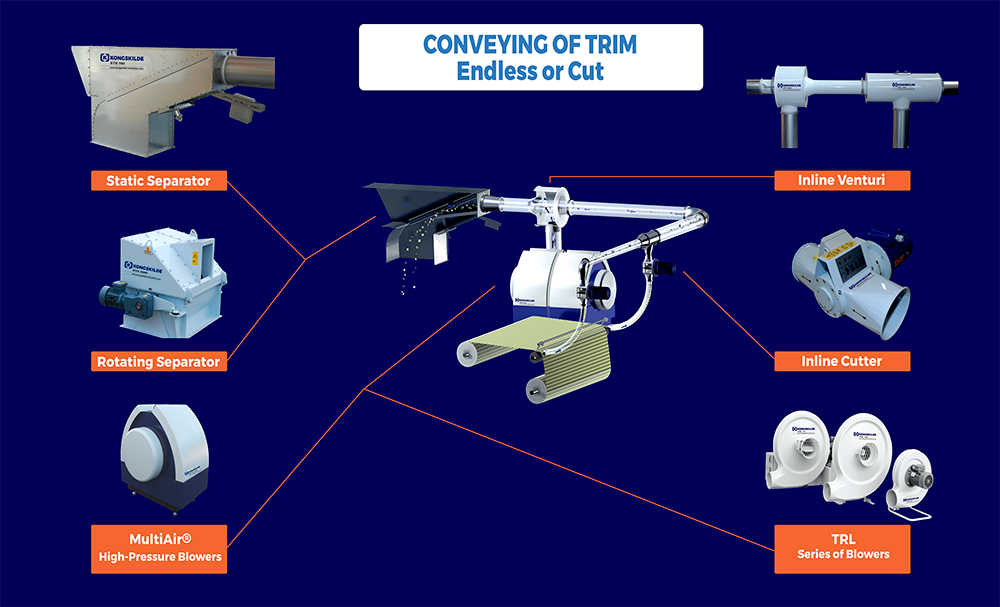

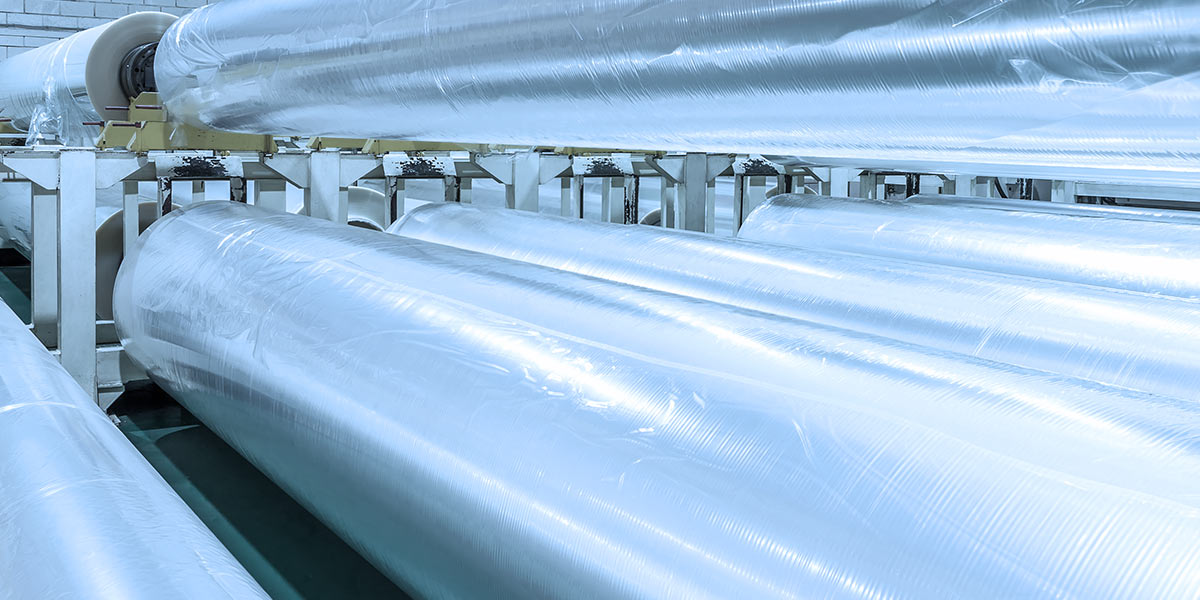

Whether you’re working with paper, cardboard, plastic foil, or aluminum, Kongskilde delivers powerful and efficient pneumatic conveying solutions for trim extraction. Our systems are engineered for performance, safety, and space-saving installation.

Kongskilde’s trim handling options include:

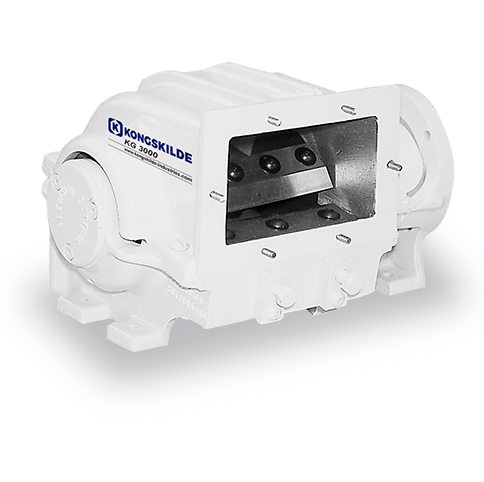

- Inline MultiCutter to reduce the volume of continuous trim

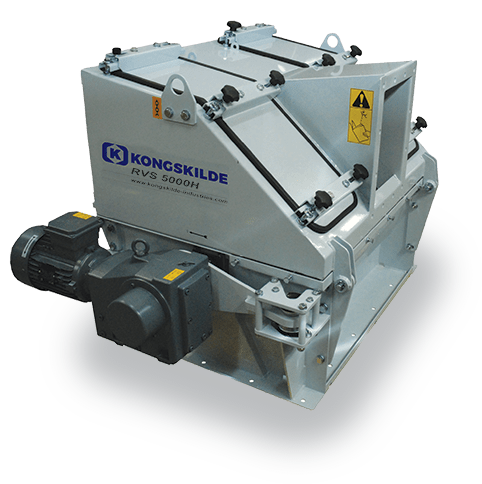

- RVS (Rotary Valve Separator) for strong suction and material separation

- STS or KU static separator at discharge points

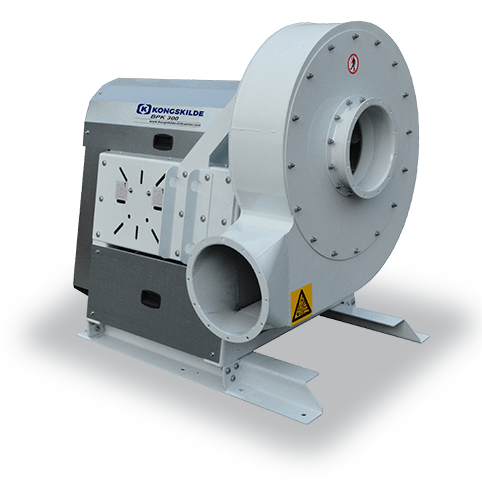

- Inline Venturi systems for long-distance suction and simple installation

Each paper trim handling machine or system can be customized to support one or multiple production lines, with flexible discharge configurations depending on the material type.

Kongskilde Cut Trim Systems and Products

Save valuable floor space by installing the flexible trim removal system wherever it fits your layout—eliminating the need for large areas dedicated to pipelines, grinders, or blowers.

Industries We Serve

Quickly remove trims from your manufacturing process, without the need to bale or compact them on the production floor. Improve productivity by eliminating production bottlenecks associated with the removal of trims. Save energy and reduce the risk of accidents on your production floor by keeping the machinery environment clean.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Trim Handling In A Clean Room For Production Of Flexible Packaging – Netherlands

A polycarbonate film & sheet producer in the Netherlands needed a pneumatic trim removal system installed in an air-controlled clean room.