Pneumatic Conveying

Aspirator Fans – FRL

Only available in North America

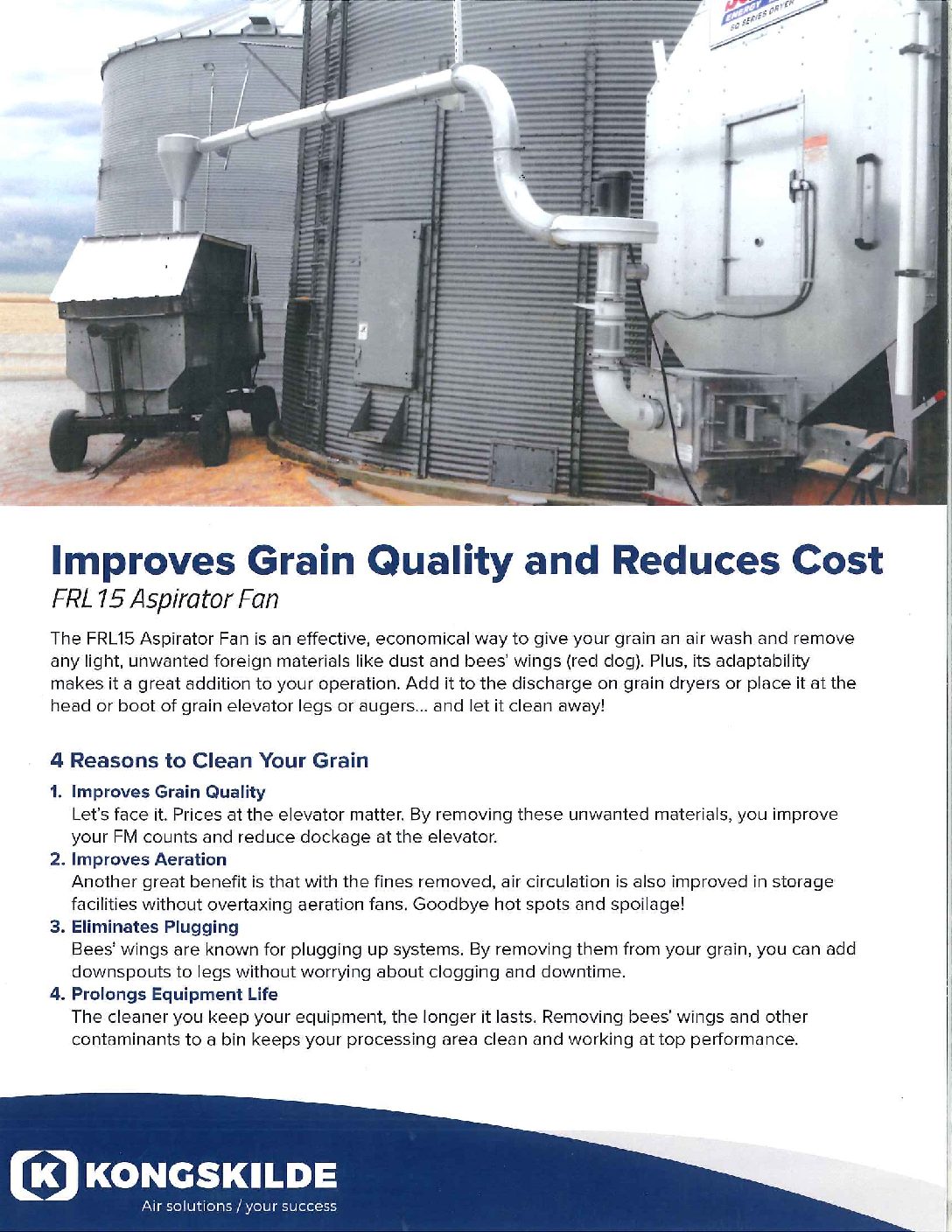

The FRL 15 Aspirator Fan is a cost-effective, efficient solution for improving grain quality by providing a powerful air wash to remove light, unwanted foreign materials such as dust, bees’ wings, and other impurities.

This aspirator fan is versatile, making it a valuable addition to your grain handling process. Whether added to the discharge of grain dryers or installed at the head or base of grain elevator legs and conveyors, the FRL 15 ensures cleaner, higher-quality grain.

Improve Grain Quality with the FRL Aspirator Fan

The FRL Aspirator Fan is specifically designed to improve the quality and marketability of your grain by removing contaminants like dust, bees’ wings, and other light debris. This fan enhances the cleanliness of your grain, contributing to more efficient storage and processing operations. Its adaptability allows it to be placed at multiple points in the grain handling system, such as the discharge of grain dryers or elevator legs, ensuring flexible integration into your existing setup.

Benefits of FRL Aspirator Fan:

- Enhances Grain Quality: Removes unwanted foreign materials, improving your grain’s FM count and reducing dockage fees.

- Boosts Grain Ventilation: With fines and debris removed, air circulation improves in storage, reducing the workload on your grain ventilation fans and preventing spoilage or hot spots.

- Prevents Clogs and Downtime: By eliminating bees’ wings and other debris, the aspirator fan prevents blockages in downspouts and other equipment, ensuring smooth operations.

- Extends Equipment Lifespan: Keeping equipment free of contaminants prolongs its life and keeps your processing area clean, reducing maintenance costs and downtime.

Downloads

Download data sheets, manual, and spare parts lists for the FRL Aspirator Fan.

FRL Aspirator Fan Applications

The FRL Aspirator Fan is ideal for use in agricultural operations where grain needs to be cleaned of dust, bees’ wings, and other light impurities. It is especially effective when installed in grain dryers, conveyors, or grain elevator systems, where removing these contaminants helps improve grain quality and airflow for long-term storage.