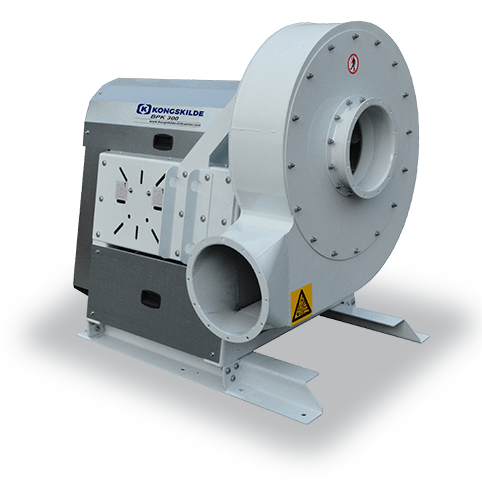

Conveying Blowers

The Kongskilde range of high pressure blowers is specifically designed as an integral part of the Kongskilde pneumatic conveying range of equipment. The Kongskilde blowers are used in connection with other Kongskilde equipment in order to convey products from the plastic, packaging and printing industries. For further information contact us or select your product below.

Conveying Blowers The Power of Air

A wide range of equipment – manual, semi-automated and automated – is used in bulk material handling, involving consideration of the storage, control and protection of conveyed material.

Bulk handling systems focalise on equipment for handling dry materials, such as plastic granulates and recycle flakes. It is an essential process in many industries. The conveyor equipment facilitating the material handling can be composed of various equipment. Pneumatic conveying equipment, for one, is used to create cost-effective material handling systems.

An industrial blower can behave as an air movement device for this type of conveying system. High-pressure blowers act as power sources in many of the reliable and effective solutions we have available at Kongskilde Industries.

Modern Pneumatic Conveyor Systems

Historically, weaker fans were used to provide the air to the system, limiting conveying to light materials in low quantities. Modern industrial blowers are equipment which facilitate material transfer at much higher throughputs and over significantly longer distances. They also tend to have lower noise levels, weatherproofing, and it is possible for certain models to either be placed inside or outside the production area.

Industrial blowers can be implemented at the beginning of the bulk material handling equipment line, to deliver an overpressure, otherwise they are found at the end of the line generating a vacuum. Blowers can also be used in cleaning and exhaust processes.

Industrial blowers have centrifugal fans, with forward or backward curved blades, that increase the pressure of incoming airstreams using impellers- accelerating air radially and altering outward flowing air direction.

Finding the Right Industrial Blower

Selecting the right industrial blower is an important decision in the area of material handling conveyor equipment: errors influence material flow rate and may necessitate changes to system sizing and design. Blockage may occur where active air flow is lowest within the system if equipment selection is inappropriate. Kongskilde Industries can and will assist in the consideration of all these factors and more, ensuring that the right decision is made.

Awareness of pressure levels and the volume of flow rate needed to move material through the bulk material handling equipment is important, as these factors can impact the conveyor system’s reliability. Information regarding the pipe sizing, distance and weight of material is also relevant.

Forward curved fans are well suited for low-speed and low-pressure applications. Backward curved fans produce medium to high airflow and produce the highest operating speeds. Various models of centrifugal fans are designed to serve particular needs in industrial application, based on specific air flow rate, pressure, volume and efficiency requirements. Many of our models are even equipped with self-cleaning rotors.

Kongskilde Industries offers effective conveying equipment: some blowers are designed for clean air transport, others for ventilation and many host centrifugal units for the handling of material. Simply recognizing that specific products serve best in certain instances and are often designed for specific tasks, makes the selection process a logical, stress-free one we are happy to support and direct.

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.