The Challenge

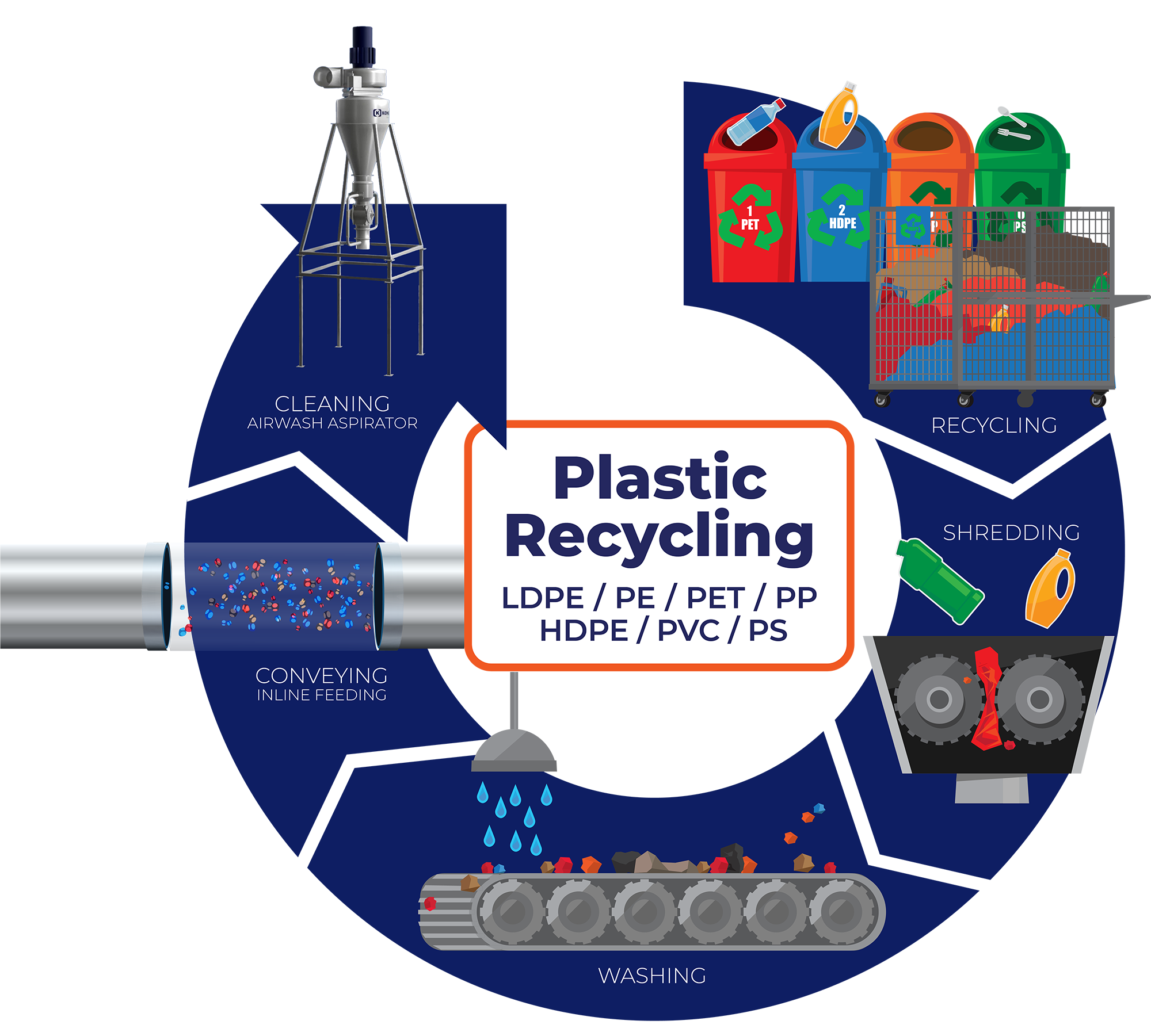

In Poland, a plastics recycling plant faced a critical need for regrind cleaning. Kongskilde provided a tailored solution for separating and dedusting light fractions and dust from post-milling materials, ensuring higher quality flakes and regranulates.

Our patented AirWash system enables operators to efficiently remove dust from reprocessed material, ensuring the highest quality flakes and regranulates. Beyond the clear benefit of obtaining clean recycled material, this solution contributes to a healthier work environment by significantly reducing dust, leading to improved employee well-being, accident prevention, and enhanced equipment durability.

The Facts

- Material Specifications:

- Material: PE dust, PET dust

- Bulk density: 450-710 kg/3

- Flake size: max. 15x15mm

- Regrind percentage: 100%

- Throughput: max. 1000kg/h

- Volume of dust: max. 10%

- System Specifications

- Max conveying distance: 10m

- Max number of bends: 3

The Solution

- Kongskilde introduced an effective cleaning solution, accommodating regrind from various sources—directly from the mill, mixer discharge, or the suction head discharge from a big bag or octabin.

- Pneumatic collection of the ground material is facilitated through the AirWash device, which simultaneously vacuums and cleans the material.

- Our solution involves a thorough cleaning process, passing through cyclone and cascade sections, adjusting through zigzag vacuum nozzles, and gravity-discharging via a sealing rotary valve.

- Dust and finer fractions are directed through a fan for suction, entering a bag filter before falling into 200-liter drums, serving as convenient dust tanks.

- Clean material, processed beneath the AirWash, is stored in a big bag or can be further transported using pneumatic means.

The Advantages and Benefits

Revolutionizing plastic recycling, Kongskilde’s innovative cleaning solution seamlessly handles regrind from various sources, employing cutting-edge technology for pneumatic collection and cleaning with the AirWash device.

- Increased production efficiency maximizes operational output.

- The production of higher-quality regranulate ensures better end products.

- The supply of high-quality regrind contributes to customer retention and expansion.

- Enhanced re-use of production waste leads to resource optimization.

- Improved processes increase revenue growth potential.

- Improved cleanliness and reduced maintenance costs create a more sustainable production environment.

- Reduced accidents and redundancies enhance workplace safety and efficiency.

- Modular components facilitate easy and flexible installation within existing production facilities.

Download the full case study:

Ready to see more?

See how Kongskilde’s air-based solutions solved problems in different industries.