Downsizing Cutters Granulators

Kongskilde’s downsizing cutters and granulators provide high-performance solutions for reducing bulk materials into smaller, manageable sizes for recycling or disposal. These systems are designed to handle a wide range of materials, offering precise cutting and granulating to enhance further processing and reduce waste.

How Kongskilde Cutters and Granulators Work

Kongskilde cutters and granulators operate by mechanically cutting or shredding materials into smaller pieces. Cutters are typically used for slicing larger items, while granulators break down materials into fine granules using a series of blades. This process is crucial for recycling operations, where reducing material size can significantly aid in the efficient reuse and handling of resources.

Benefits of Kongskilde Downsizing Cutters and Granulators

To better understand the value Kongskilde downsizing cutters and granulators bring to your operations, here are several key benefits they offer:

- Increased Processing Efficiency: Speeds up the recycling process by breaking down materials into uniform sizes.

- Cost-Effective: Reduces transportation and storage costs by minimizing the volume of waste material.

- Improved Waste Management: Facilitates easier sorting and handling of recycled materials.

- Versatility: Capable of processing a variety of materials, from plastics and papers to metals and textiles.

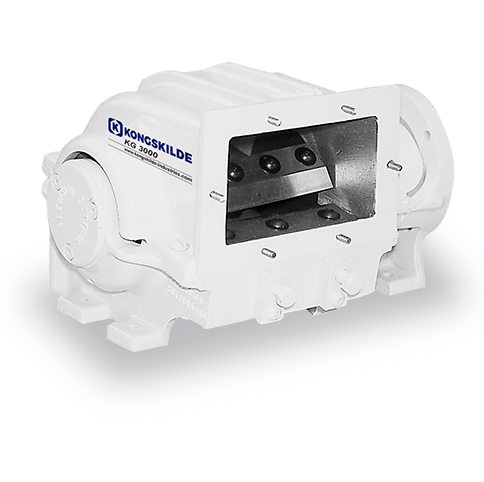

Compare Cutter Models

Compare available Kongskilde Cutter models

| Cutter Model | Paper / Cardboard | Plastic / Soft Flexible | Aluminum Foil |

|---|---|---|---|

| MultiDicer | 90 – 800 g/m2 | NA | NA |

| MultiCutter | up to 400 g/m2 | 10 – 400 µm | 10 – 150 µm |

| MC 3000 FS | up to 800 g/m2 | 20 – 500 µm | 20 – 300 µm |

| MC 3000 F | up to 800 g/m2 | 35 – 500 µm | 35 – 300 µm |

| KG 3000 FS | NA | 20 – 500 µm | 20 – 300 µm |

| KG 3000 F | NA | 35 – 500 µm | 35 – 300 µm |

| MC 5000 F | up to 800 g/m2 | 35 – 500 µm | 35 – 300 µm |

| KG 5000 F | NA | 35 – 500 µm | 35 – 300 µm |

| GR/MCB 100 | 40-120 g/m2 | 40-150 µm | 40-80 µm |

| GR/MCB 160 | 40-400 g/m2 | 40-400 µm | 40-150 µm |

| GR/MCB 180 | 40-400 g/m2 | 40-400 µm | 40-150 µm |

| GR/MCB 200 | 40-600 g/m2 | 40-500 µm | 40-300 µm |

FAQ: Downsizing Cutters and Granulators

What materials can be processed with Kongskilde cutters and granulators?

Kongskilde’s downsizing cutters and granulators are versatile and can process a wide range of materials including plastics, paper, cardboard, textiles, and light metals, making them suitable for multiple industries such as recycling, manufacturing, and waste management.

How do I choose the right Kongskilde cutter or granulator for my needs?

Choosing the right Kongskilde cutter or granulator depends on several factors, including the type of material you need to process, the required size of the output, and your production capacity. Kongskilde offers various models with different capacities and customization options to meet specific operational needs.

Are Kongskilde cutters and granulators environmentally friendly?

Yes, Kongskilde cutters and granulators are designed to be environmentally friendly. They help reduce landfill waste by efficiently downsizing materials for recycling, contributing to more sustainable waste management practices. Additionally, they are engineered to operate with high energy efficiency and low emissions.

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.