Downsizing Cutters & Granulators

MC 3000 – 5000 Cutters

The MC 3000/MC 5000 is developed for continuous cutting of continuous trim.

The MC 3000/MC 5000 consists of a fixed and rotating set of blades driven by a direct-coupled motor. The angled rotating blades provide shock-free cutting and reduce the operating noise level.

The MC 3000/MC 5000 is installed in a pipe system in connection with either paper and printing press machinery or post-processing machinery. For handling paper trims, cardboard trims, or plastic film.

The MC 3000/MC 5000 Cutter

The MC 3000/MC 5000 is developed for continuous cutting of continuous trim. It consists of a fixed and rotating set of blades driven by a direct-coupled motor. The angled rotating blades provide shock-free cutting and reduce the operating noise level.

Benefits

- The shaftless cutting chamber and the fact that the end discs of the rotor serve as part of the cutting chamber prevent any chance of wraps.

- Knives are supplied in standard hardened steel with good resistance to wear and extended service life. These knives typically last 10 times longer than standard knives.

- The rotor is mounted in ”seal for life” precision ball bearings.

Downloads

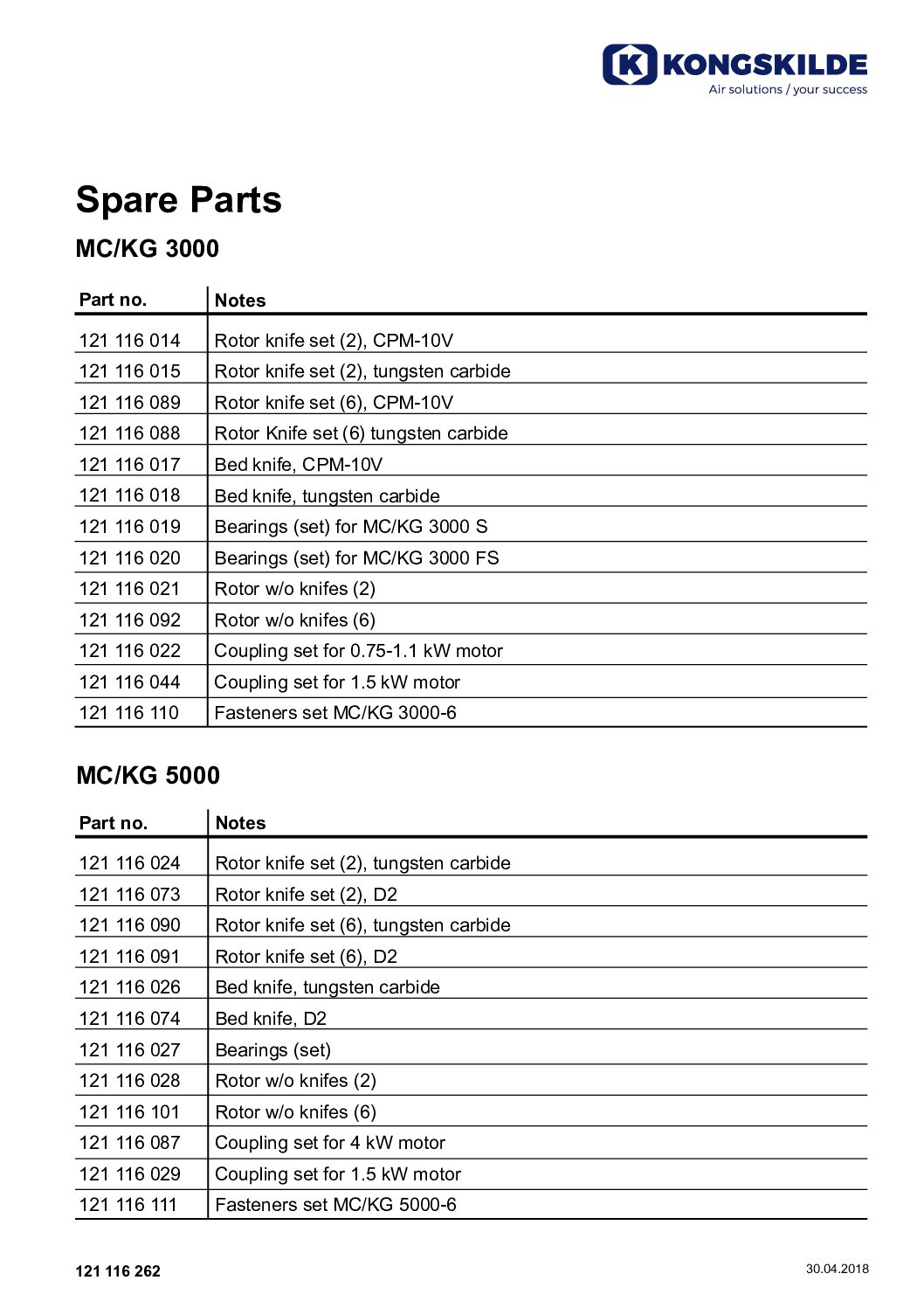

Download data sheets, manuals, and spare parts lists for the MC 3000 / MC 5000.

MC 3000/MC 5000 Model Comparison

Visit the downloads section for additional technical information.

| MC 3000 (2900 RPM) | MC 3000 (1450 RPM) | MC 3000 (900 RPM) | MC 5000 (2900 RPM) | MC 5000 (1450 RPM) | MC 5000 (900 RPM) | |

|---|---|---|---|---|---|---|

| Motor Size | 1.5 kW or 0.75 kW | 0.75 kW | 0.55 kW | n/a | 4 kW or 1.5 kW | 1.1 kW |