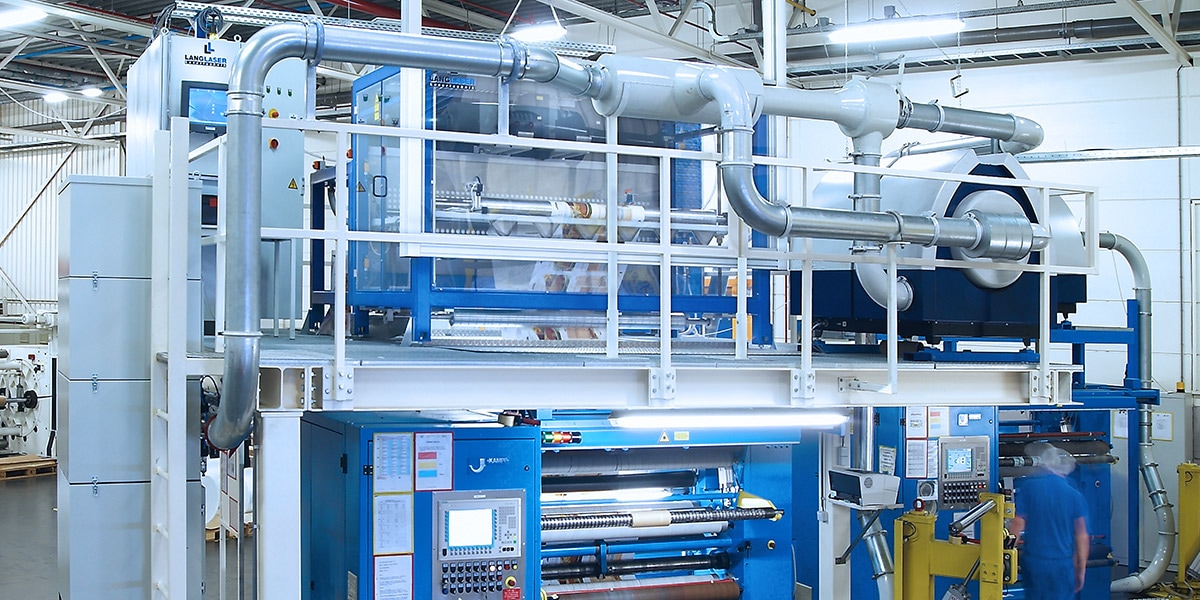

Conveying Lines – Pipes

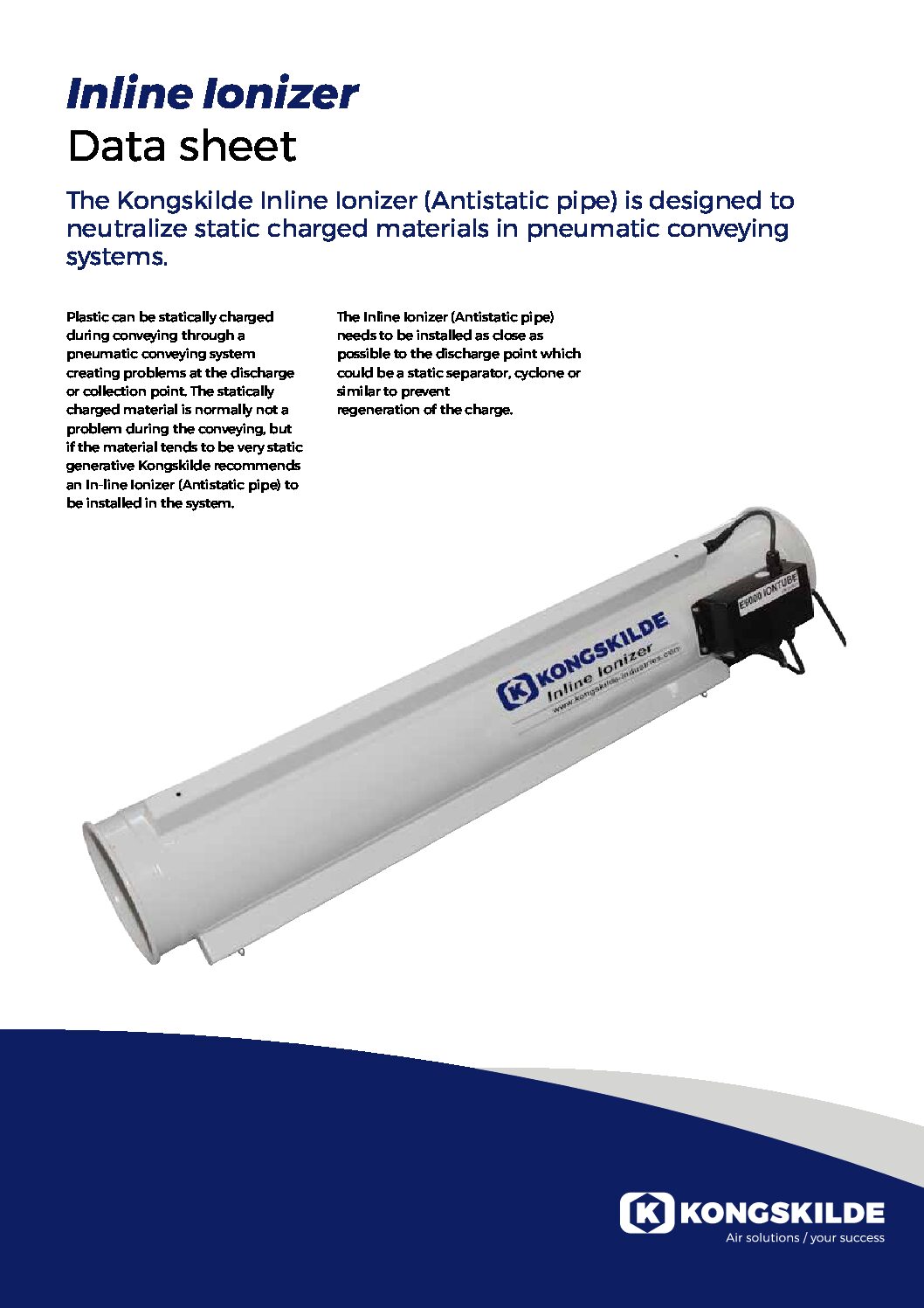

Inline Ionizer

Eliminate Static Build-Up for Uninterrupted Material Flow

The Kongskilde Inline Ionizer is designed to neutralize static charges in pneumatic conveying systems, preventing material clogs and improving efficiency.

By eliminating static buildup, materials such as granulates, plastic edge trims, and reprocessed materials flow freely through the system, reducing downtime and increasing productivity.

Designed to neutralize statically charged materials

Static electricity can accumulate in a wide range of materials during processing and conveying. This is particularly common in:

- Plastic and paper slitter trims

- Granulates and reprocessed materials

- Containers, bags, and sacks used in production

While static buildup may not always disrupt conveying, excessive static charges can cause clogs at discharge points, leading to inefficiencies in production. The Kongskilde Inline Ionizer effectively neutralizes these charges, ensuring smooth material flow.

Applications

- Process waste material, like thin plastic foil, clinging to the inside or outside of a discharge box, cyclone, container, etc.

- Contamination of virgin materials in pneumatic conveying lines.

- Undesired separation of virgin and reclaimed material due to static charges.

- Hazardous static charges on machine surfaces.

Benefits of Kongskilde Inline Ionizer

- Prevents material blockages in pneumatic conveying systems.

- Improves productivity by ensuring smooth material flow.

- Eliminates static contamination, reducing material waste.

- Enhances workplace safety by neutralizing hazardous static charges.

- Compact and easy to install in existing pneumatic conveying setups.

Inline Ionizer Downloads

Download manuals and data sheets for the Kongskilde Inline Ionizer.