Monitoring & Service

CORE

Cloud-based platform for monitoring equipment data and accessing machines remotely

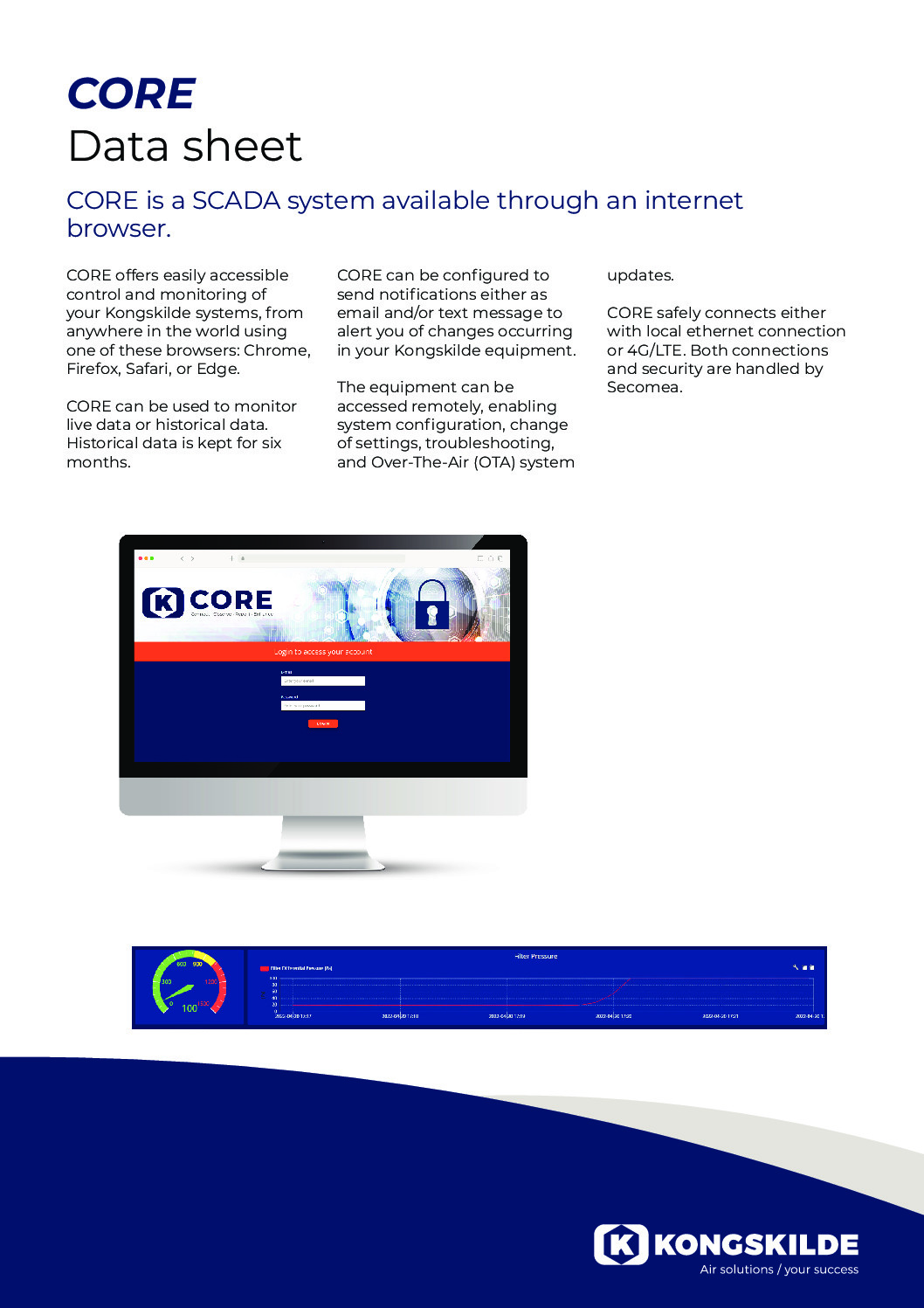

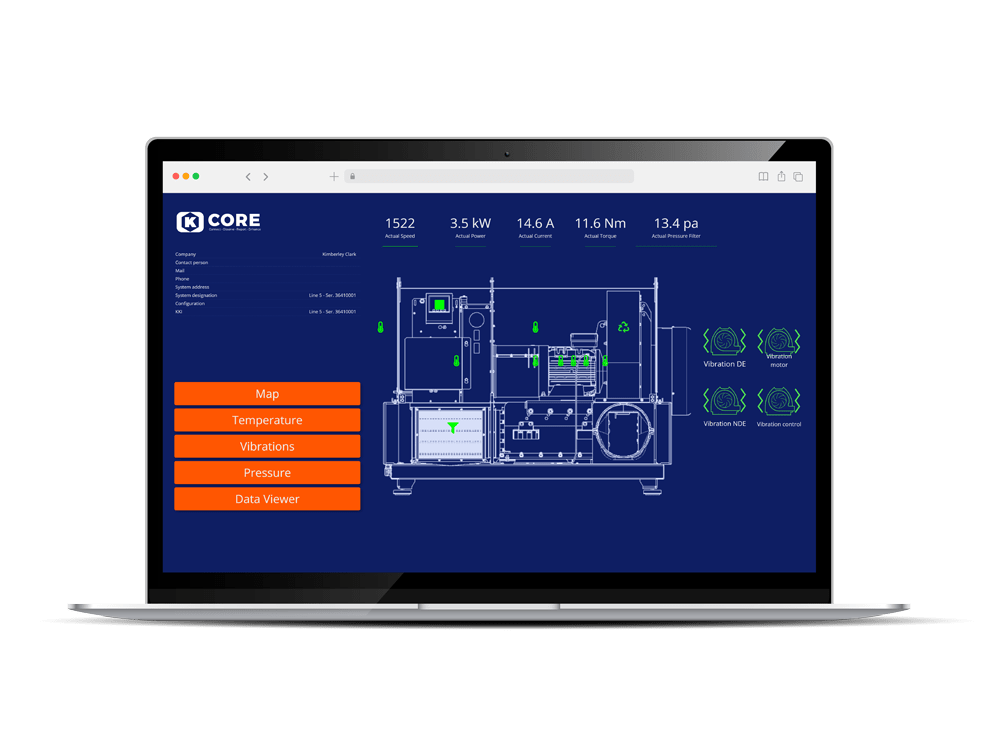

CORE is a powerful, cloud-based equipment monitoring software designed to provide real-time insights and remote access to your Kongskilde equipment. Accessible from any browser, CORE enables you to monitor, manage, and optimize your equipment anywhere, anytime, ensuring smooth operations and maximizing production efficiency. With its intuitive dashboard, CORE gathers and displays valuable data on equipment performance, maintenance needs, and operational history, helping users troubleshoot issues quickly and proactively schedule maintenance.

Collect. Observe. Report. Enhance.

CORE simplifies industrial equipment monitoring by centralizing data collection, visualization, and reporting. Built on a secure cloud platform, CORE turns data into actionable insights that enhance fleet management and production workflows. The system connects to your equipment via an industrial IoT gateway, providing secure and continuous data access and monitoring.

Benefits of CORE Industrial Equipment Monitoring Software

CORE offers significant advantages for industrial operations, supporting efficient maintenance and optimized equipment performance:

- Preventive Maintenance: Monitor equipment performance and set service intervals based on data, preventing wear and reducing the likelihood of unexpected breakdowns.

- Fast Troubleshooting: Remote access enables technicians to resolve issues quickly, reducing downtime and eliminating the need for in-person troubleshooting.

- Enhanced Productivity: Live alerts and historical data analysis help identify and resolve issues before they impact production, ensuring minimal interruptions.

- Cost Savings: CORE’s predictive maintenance and optimized service scheduling reduce operational costs by preventing unnecessary repairs and minimizing service calls.

- Comprehensive Fleet Management: Manage and monitor all connected Kongskilde equipment through one platform, simplifying fleet oversight and performance tracking.

Highlights

- Live System Status: Monitor critical metrics such as pressure, temperature, vibration, and motor health, ensuring early detection of potential issues.

- Over-the-Air Software Updates: Keep equipment updated with the latest features and improvements remotely, extending the lifespan and functionality of your machinery.

- Intuitive HMI Panel: CORE’s user-friendly interface provides clear visuals and simple navigation for quick access to data and settings.

Applications of CORE Equipment Monitoring Software

CORE is designed for industrial settings where continuous monitoring and remote management are essential. Ideal applications include:

- Manufacturing Facilities: Monitor equipment status, set preventive maintenance schedules, and respond to alerts to maintain high productivity.

- Production Plants: Ensure safe and efficient operation of critical equipment, minimize downtime, and improve resource allocation.

- Heavy Equipment Operations: Track performance data on vital equipment like compressors, blowers, and ventilation systems to reduce wear and prolong service life.

CORE Videos

Learn more about service and monitoring with CORE.