The Challenge

SABIC Snij-Unie handles a wide range of LEXAN™ polycarbonate film and sheet materials by cutting smaller rolls, sheets, making shorter rolls, or laminating basic materials supplied by customers. Continuous edge trim from the slitting and winding operations must be removed quickly to maintain production speed and keep the area clean.

The trim extraction system had to meet strict clean room requirements while still providing reliable pneumatic conveying:

- Clean room location made standard extraction layouts unsuitable.

- Air removal had to be minimized to protect temperature, humidity, and stability.

- No filter could be installed in the clean room, so equipment was placed in an adjacent packing room.

- To limit loss of conditioned air, equipment is placed externally.

- Conveying and separation had to protect clean-room integrity and allow easy, safe service access.

The Facts

- Material: foil, polycarbonate/polyester

- Material thickness: 50 μ – 380 μ

- Trim width: 50 mm

- Number of trims: 1 per pick-up point

- Speed: 40–100 m/min

System Specifications:

- Max conveying distance: 20 m

- Max number of bends: 5 × 90°

- Pipes run from the clean room through an attic space into the adjacent packing room where the separator equipment is placed.

The Solution

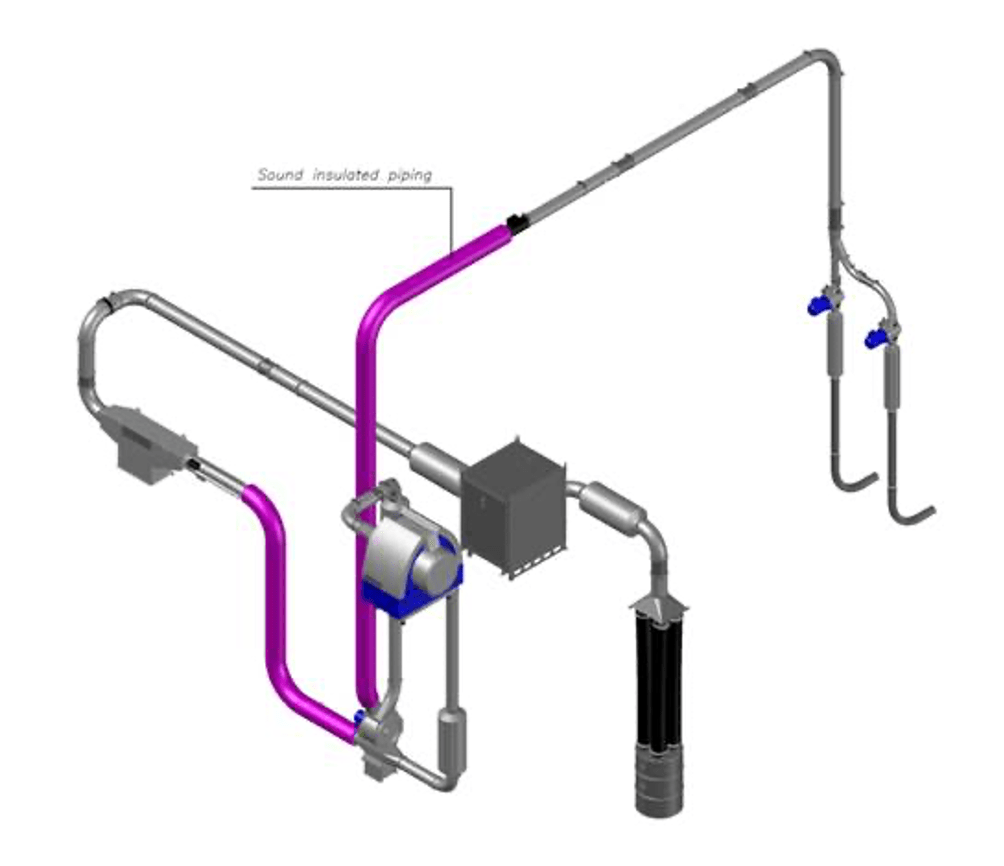

The trim extraction system collects waste at clean-room pick-up points and conveys it through through the attic into an adjacent packing room with separator equipment.

- Pick-up points in the clean room capture trim directly at the slitting and winding machine to protect production speed and cleanliness.

- Two flexible steel pick-up points with MultiCutters downsize trim at source for stable airflow and conveying over the required distance.

- Shredded trim is conveyed in an OK 160 pipeline through the attic to separator and filter units located in the packing room.

- Locating blowers, separators, and filters outside the clean room simplifies maintenance from the controlled area and reduces contamination risk.

The system features two suction points with dedicated MultiCutters, a fire damper, a MultiAir® FC 2190 blower, and an MTD 22 blower located in a sound booth. Filtration and separation are handled by a four-bag filter unit, an RVS 75 separator in a sound cabinet, and an STS 160 separator with an anti-static unit. The installation also includes partly sound-insulated OK 160 piping and piping leading to an adjacent packing room with separator equipment.

The Advantages and Benefits

Kongskilde’s pneumatic trim handling system provides clean, reliable, and efficient extraction for SABIC Snij-Unie’s clean room production. By placing all key equipment outside the controlled room and using dedicated downsizing and separation units, the system protects the clean room environment, reduces manual work, and helps maintain stable air, temperature, and humidity conditions.

- Improved cleanliness: No waste handling occurs inside the clean room, making the process cleaner and reducing the risk of contamination in the controlled area. Trim is extracted directly at the machine and conveyed out of the room.

- Enhanced productivity: Manual labour of removing trim has been replaced by the pneumatic trim suction system, saving considerable operator time, simplifying housekeeping around the slitting machine, and supporting increased productivity.

- Quieter working environment: Sound-reduced blower installation and partly sound-insulated piping lower noise levels from the conveying system, contributing to a better and more comfortable working environment for operators.

- Consistent trim removal: MultiCutters, blowers, separators, and conveying pipes work together to ensure that trim is removed continuously from the production line at the required speeds, helping to keep production flow stable.

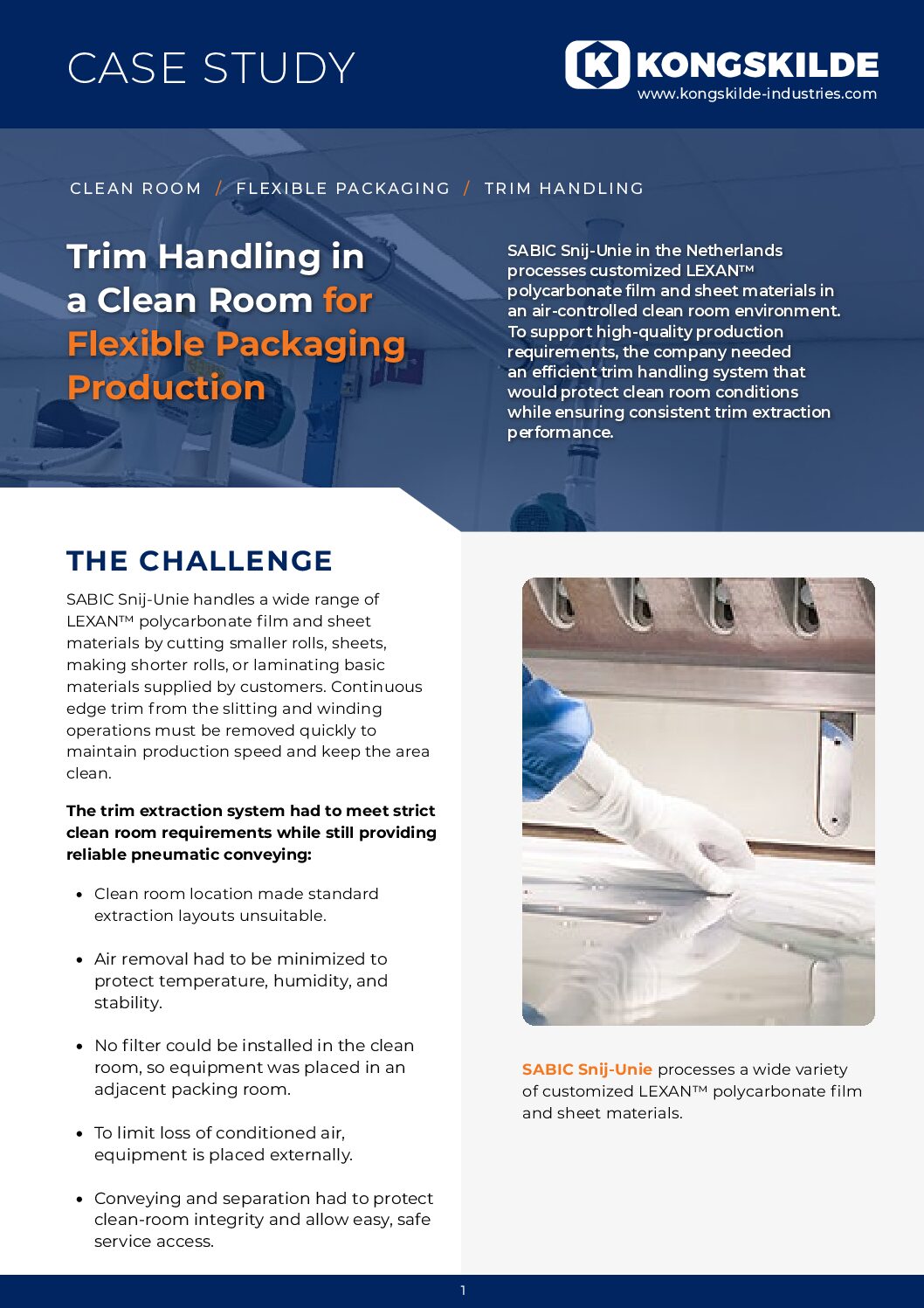

SABIC Snij-Unie processes a wide variety of customized LEXAN™ polycarbonate film and sheet materials.

MultiCutters capture and shred trim waste at the winding and slitting machine. The two lines join into one main pipe that transports the material to the waste bin.

The MultiAir® FC blower is installed outside the clean room to provide consistent airflow to the system. Its variable speed control allows it to adjust to the required demand, ensuring optimal energy efficiency during operation.

Download the full case study:

Featured Products

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.