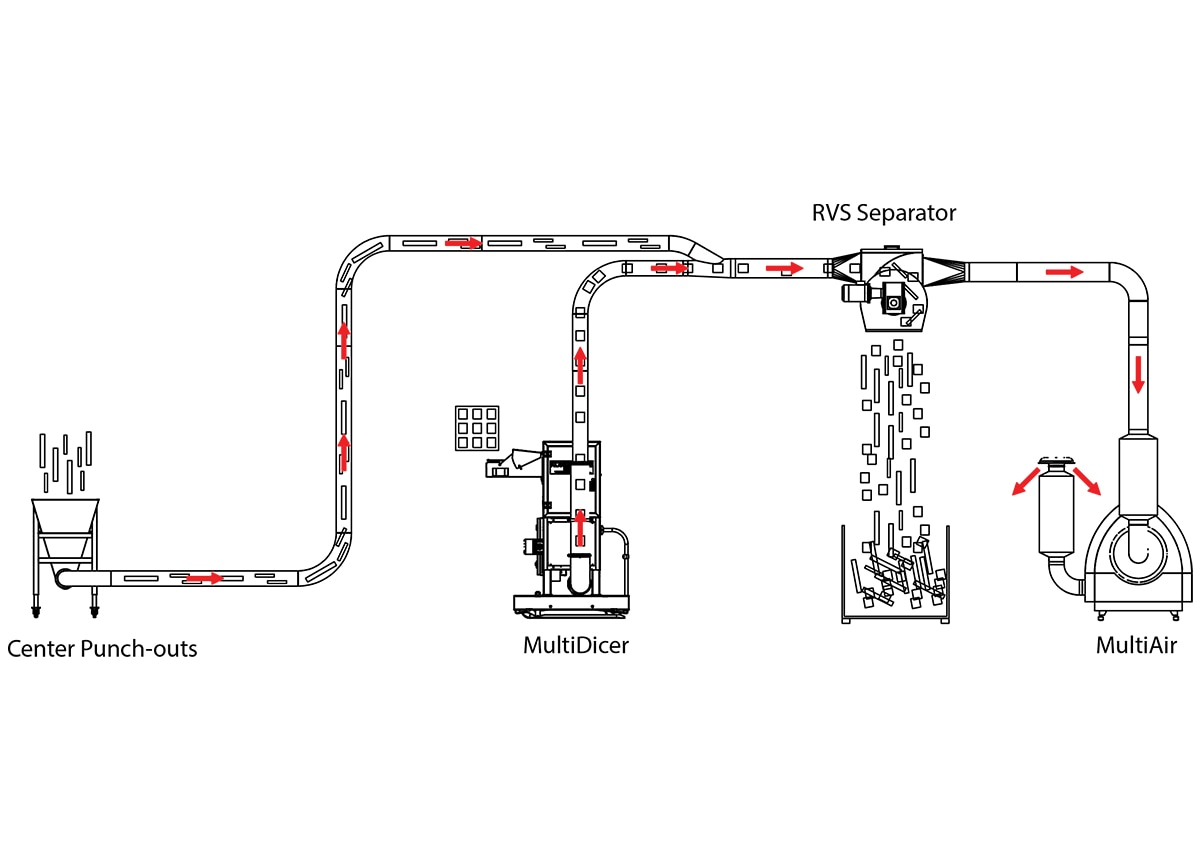

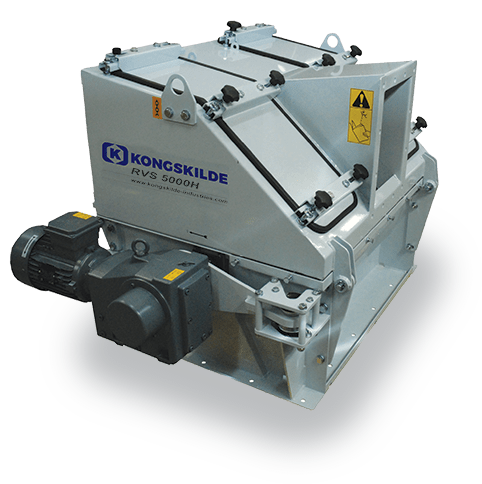

The MultiDicer

Kongskilde’s MultiDicer has been designed specifically for dealing with die-cut waste. The MultiDicer downsizes the cardboard or carton board skeleton waste released from a die cutter. This minimizes the size of the conveying pipes, which then reduces the demands on space for the installation.

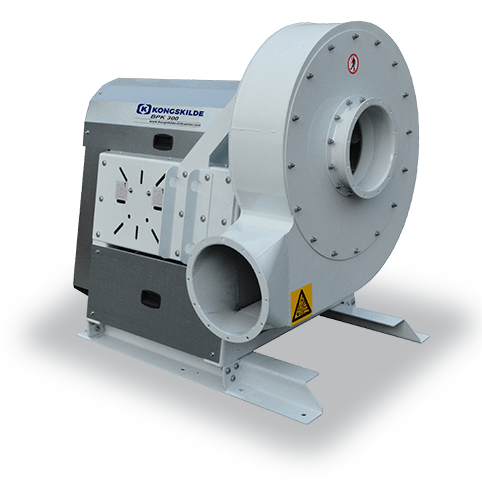

Small diameter conveying pipes means less air to handle, which reduces overall power consumption.

Further benefits include a minimum amount of conditioned air removed from the production area, as well as the operator being able to focus on running the die cutter efficiently without the need to stop to empty waste containers.

Video of Pneumatic Solution for Conveying of Skeleton Waste

Direct from Die Cutter to Compactor.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Conveying of Regrind Plastic Material without Dust – Food Packaging – Poland

A pneumatic solution from Kongskilde for the conveying of regrind material minimizes dust and improves productivity.