Downsizing Cutters & Granulators

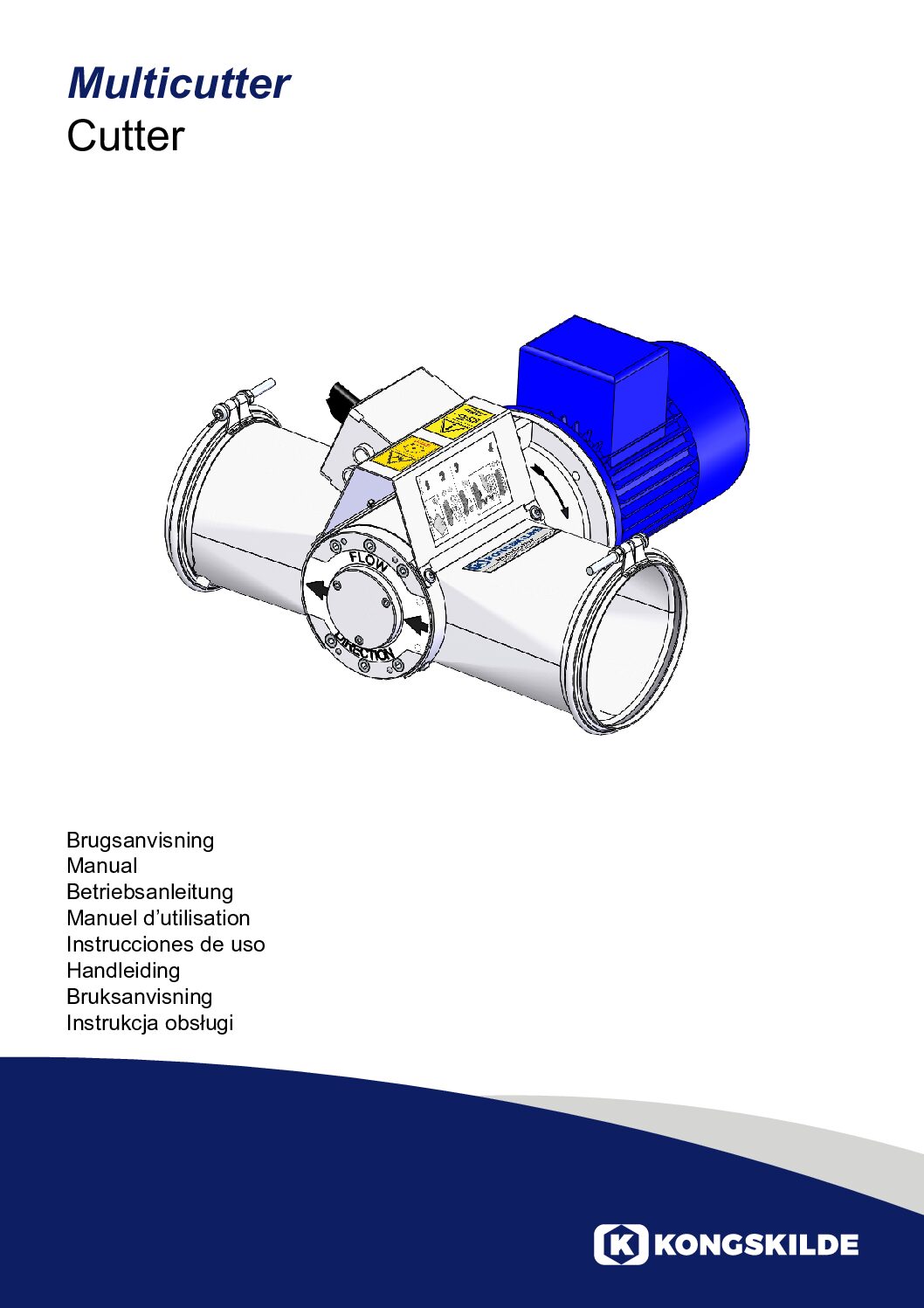

MultiCutter

Developed for continuous cutting of waste edge trim from machines for film blowing, packaging, paper production, and slitters

Discover the efficiency and precision of Kongskilde’s MultiCutter, a continuous cutter designed for seamless integration into production lines. Perfect for handling various materials, our MultiCutter ensures consistent, high-quality cutting with minimal downtime.

The MultiCutter is available in both 50 Hz and 60 Hz models.

How Our MultiCutter Works

The Kongskilde MultiCutter operates with a rotating set of blades and a fixed knife, driven by a direct-coupled motor. This design allows for continuous, precise cuts without the need for frequent stops, making it ideal for high-volume production environments.

Benefits of Kongskilde’s MultiCutter

- Enhanced Durability: Blades made from specially hardened steel resist wear and extend the cutter’s life.

- Low Maintenance: Easy blade adjustment and resharpening with bearings lubricated for life, requiring no further greasing.

- Continuous Operation: Designed for non-stop use, improving throughput and efficiency in production lines.

- Versatile Cutting: Handles materials like film, foil, paper, and cardboard effortlessly.

Applications for the MultiCutter

The MultiCutter is versatile and can be used in a variety of industries:

- Packaging: Efficient cutting of excess materials from packaging lines.

- Paper Production: Precise cutting of paper products to specified dimensions.

- Film and Foil: Ideal for the film and aluminum foil industries, where exact cutting ensures product quality.

- Recycling: Assists in the downsizing of materials for easier recycling and disposal.

Kongskilde’s MultiCutter is your go-to solution for industrial cutting needs, ensuring operational efficiency with high-capacity handling. Contact us today to learn more about how our cutting solutions can integrate into your production workflow.

Cutter Maintenance & Service

We provide maintenance support and original spare parts to keep your cutter running reliably.

Downloads

Download manuals, data sheets, and spare parts lists for the Kongskilde MultiCutter.

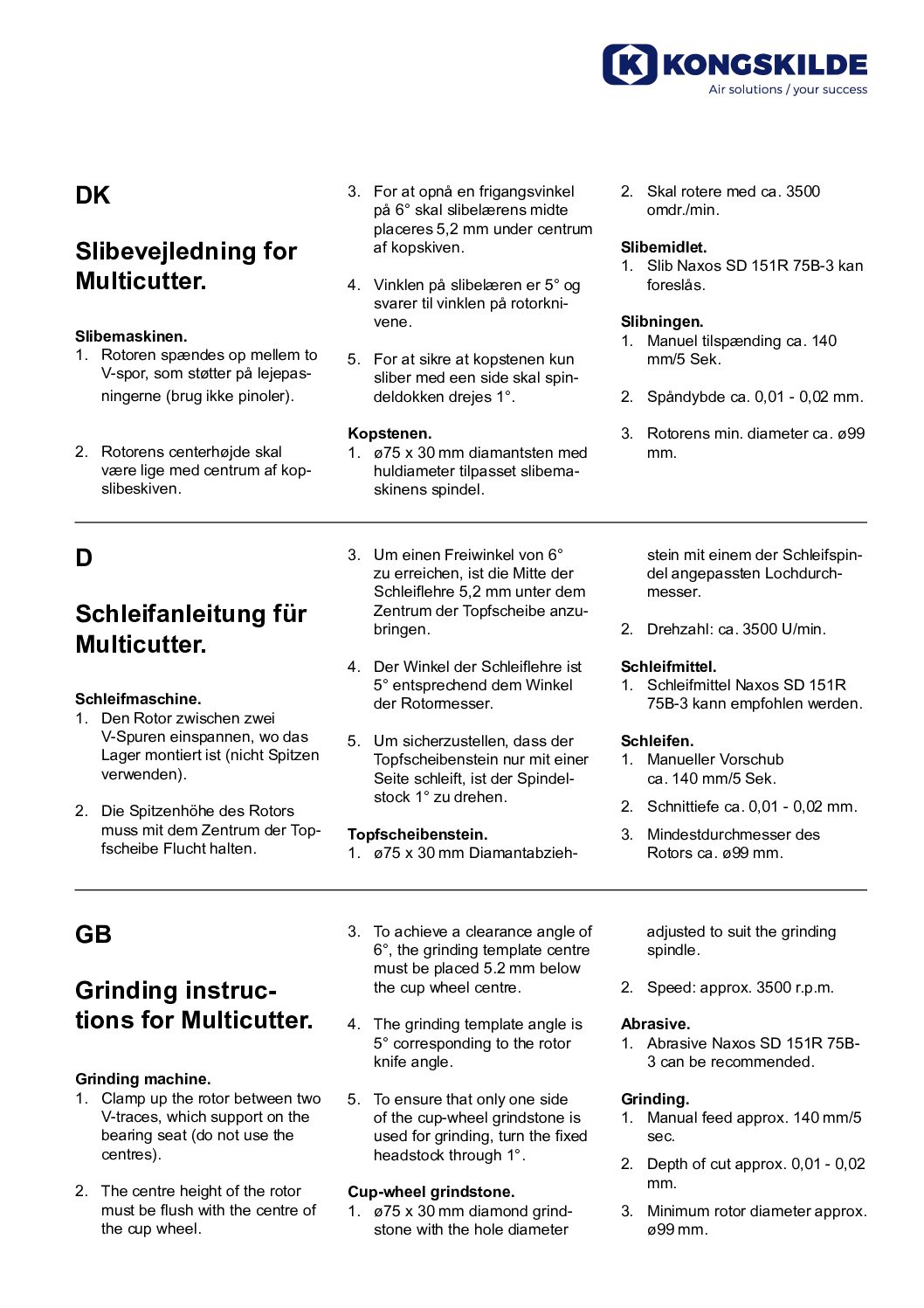

MultiCutter Model Comparison

Visit the downloads section for additional technical information.

| Material Thickness µm -Plastic (g/m2 – Paper) | Max. Thickness Corrugated mm | Max. Trim Speed Stiff Material m/RPM | |

|---|---|---|---|

| MultiCutter 2-knife rotor | 10-300 (300) | NA | NA |

| MultiCutter 3-knife rotor | 10-300 (300) | NA | NA |

| MC 3000 F 2-knife rotor | 35-500 (800) | 6.4 | 0.1 |

| MC 3000 F 6-knife rotor | 35-500 (800) | 6.4 | 0.3 |

| MC 3000 FS 2-knife rotor | 20-500 (NA) | 6.4 | 0.1 |

| MC 3000 FS 6-knife rotor | 20-500 (NA) | 6.4 | 0.3 |

| KG 3000 F 2-knife rotor | 35-500 (NA) | 6.4 | NA |

| KG 3000 F 6-knife rotor | 35-500 (NA) | 6.4 | 0.3 |

| KG 3000 FS 2-knife rotor | 20-500 (NA) | NA | 0.1 |

| KG 3000 FS 6-knife rotor | 20-500 (NA) | NA | 0.3 |

| MC 5000 F 2-knife rotor | 35-500 (800) | 12.7 | NA |

| MC 5000 F 6-knife rotor | 35-500 (800) | 12.7 | NA |

| KG 5000 F 2-knife rotor | 35-500 (NA) | NA | NA |

| KG 5000 F 6-knife rotor | 35-500 (NA) | NA | NA |

Video of MultiCutter

MultiCutter Applications

The MultiCutter is suitable for a variety of industries and cutting applications.