Downsizing Cutters & Granulators

MC 3000 – 5000 Cutters

The MC 3000/MC 5000 is developed for continuous cutting of continuous trim.

The MC 3000 and MC 5000 Industrial Cutter is specifically engineered for continuous cutting of trim materials, ensuring smooth and efficient processing in paper, printing, and post-processing industries. Designed with a fixed and rotating set of blades, this industrial cutter delivers shock-free operation, reducing noise levels while maintaining precision cutting performance.

The MC 3000/MC 5000 Cutter

The MC 3000 and MC 5000 Industrial Cutter features a direct-coupled motor that powers an angled rotating blade system, providing clean, efficient, and low-noise cutting. Installed within a pneumatic conveying system, it is ideal for handling paper trims, cardboard trims, and plastic film waste from printing presses and post-processing machinery.

Key Features

- Precision Cutting Technology – Fixed and rotating blades work together for efficient, continuous cutting.

- Shock-Free Operation – Angled blade design reduces vibrations and noise levels.

- Seamless System Integration – Designed for inline installation in paper, printing, and processing facilities.

- Durable & Long-Lasting Components – Built with high-wear-resistant hardened steel blades.

Benefits of the MC 3000 & MC 5000 Industrial Cutter

- Prevents Material Wraps – The shaftless cutting chamber and rotor end discs eliminate the risk of material wrapping around the cutter.

- Extended Knife Lifespan – Hardened steel blades last up to 10 times longer than standard knives, reducing replacement costs.

- Low Maintenance & High Efficiency – Equipped with “seal for life” precision ball bearings, minimizing downtime and servicing needs.

By integrating the MC 3000 & MC 5000 Industrial Cutter into your production line, you can achieve consistent material downsizing, reduced maintenance, and optimized efficiency for various industrial cutting applications.

Downloads

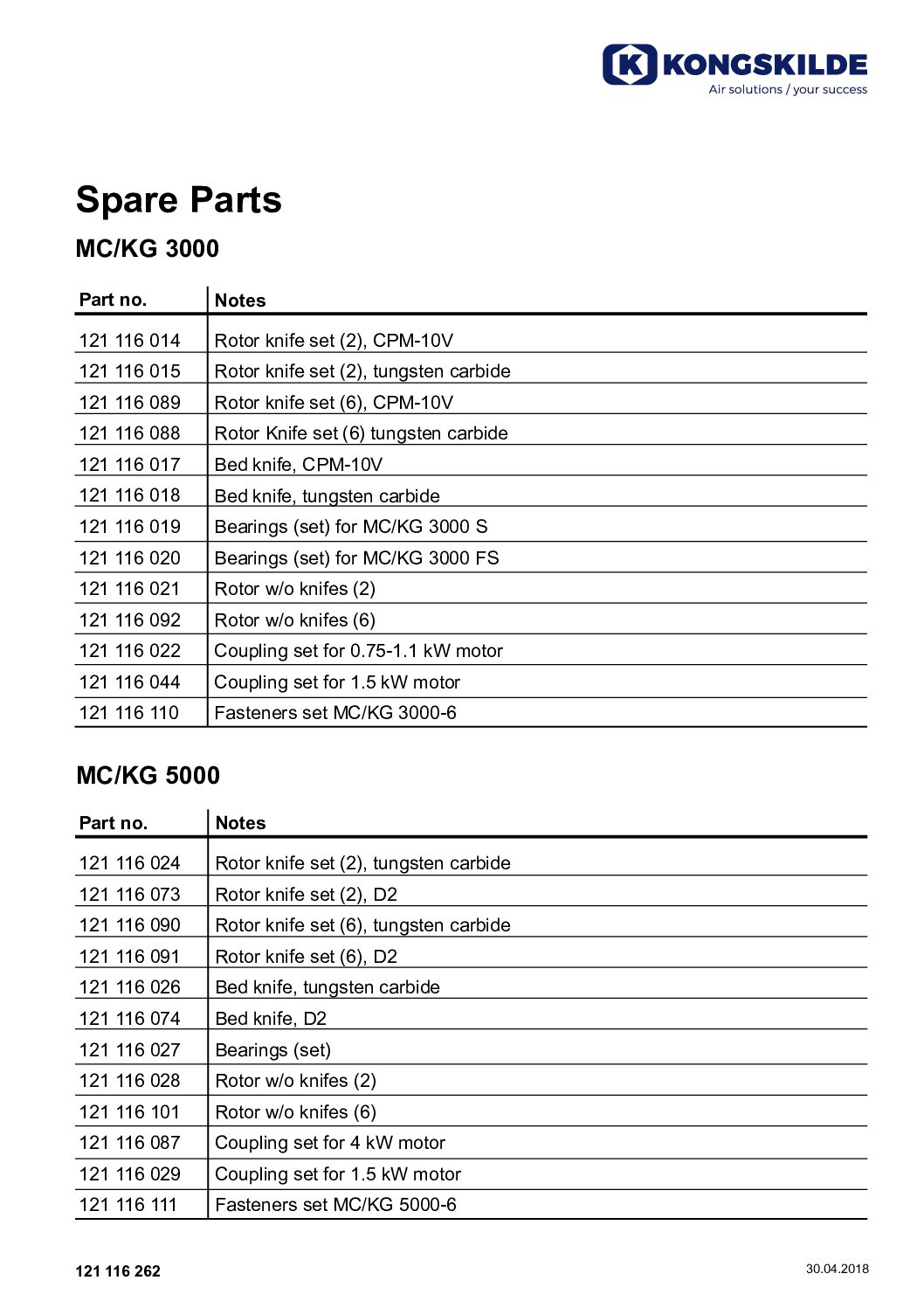

Download data sheets, manuals, and spare parts lists for the MC 3000 / MC 5000.

MC 3000/MC 5000 Model Comparison

Visit the downloads section for additional technical information.

| MC 3000 (2900 RPM) | MC 3000 (1450 RPM) | MC 3000 (900 RPM) | MC 5000 (2900 RPM) | MC 5000 (1450 RPM) | MC 5000 (900 RPM) | |

|---|---|---|---|---|---|---|

| Motor Size | 1.5 kW or 0.75 kW | 0.75 kW | 0.55 kW | n/a | 4 kW or 1.5 kW | 1.1 kW |