Air / Material Separators

KU Static Separator

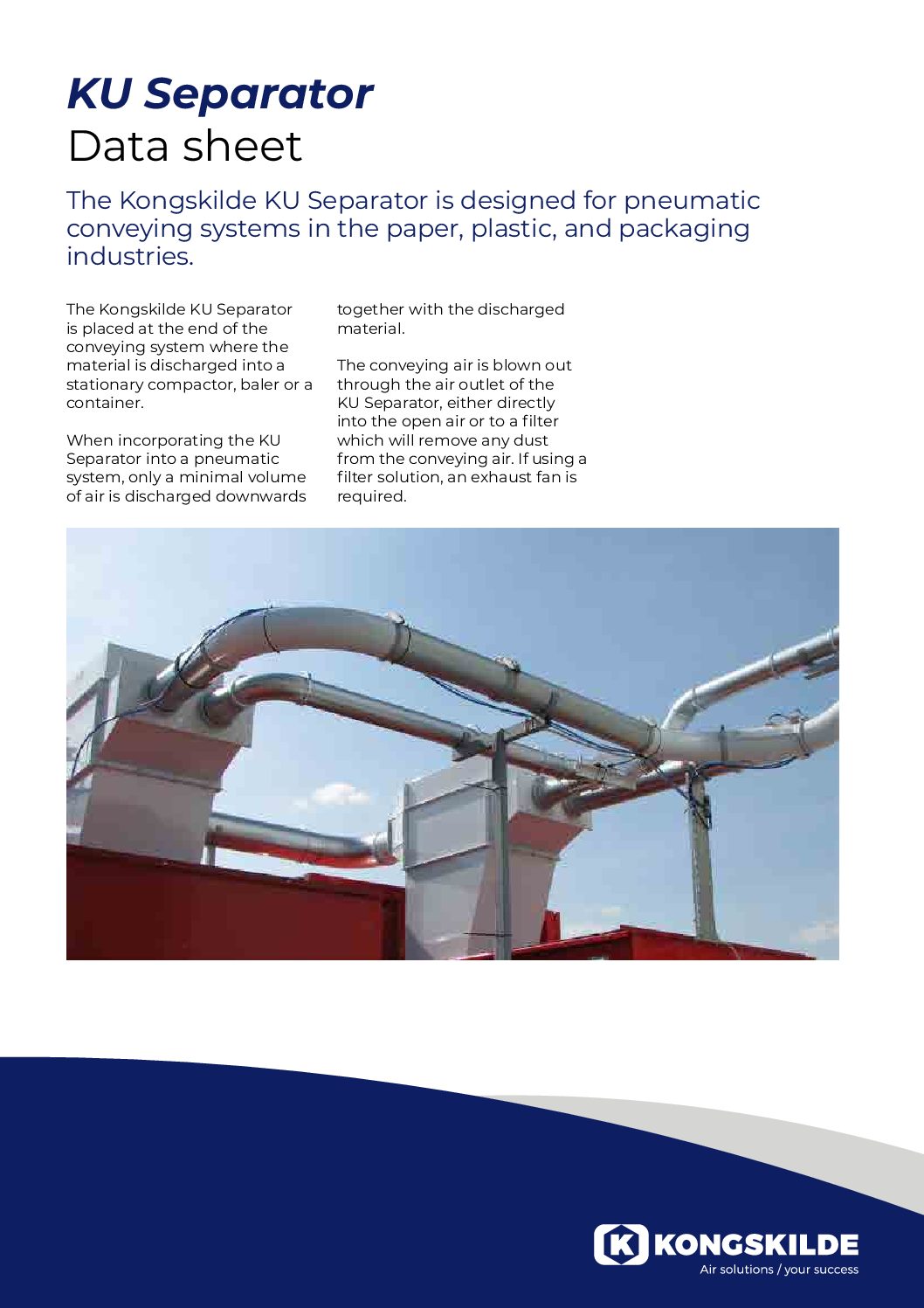

Static separator placed at the discharge end of a pneumatic system

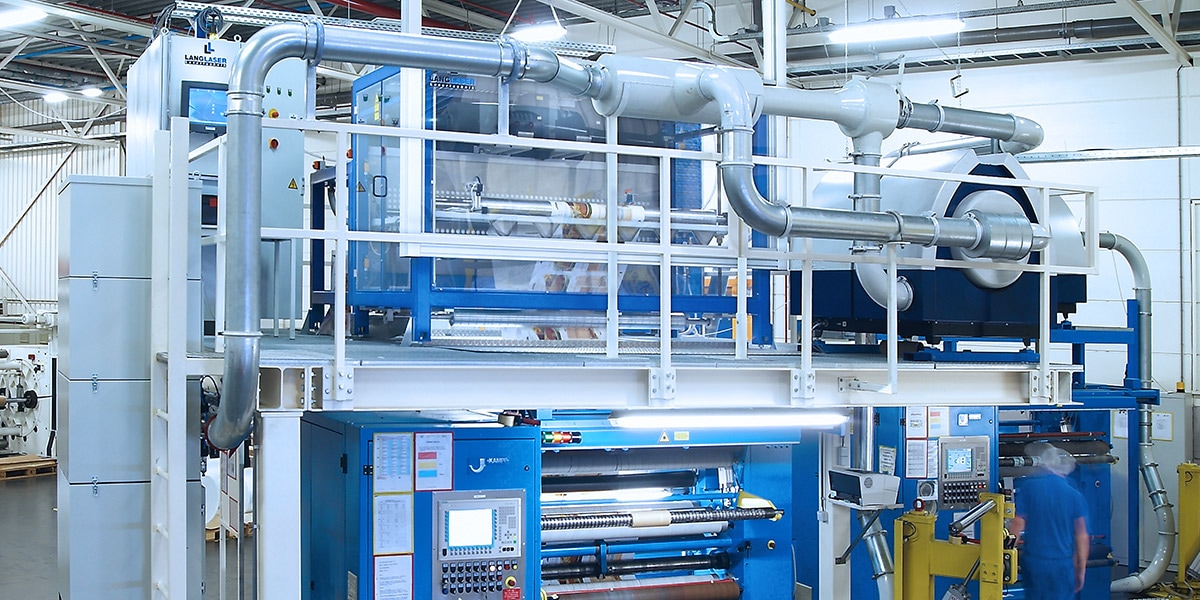

The Kongskilde KU Static Separator is designed for efficient material separation in pneumatic conveying systems, making it an ideal solution for the paper, plastic, and packaging industries.

Positioned at the discharge end of the system, the KU static separator directs bulk materials into a stationary compactor, baler, or container, while the conveying air is efficiently expelled through an outlet or directed to a filtration system.

Kongskilde KU Static Separators

By integrating the KU static separator into a pneumatic conveying system, only a minimal volume of air is released alongside the discharged material. The remaining air is vented through an outlet—either directly into the open air or through a filter system to remove dust and maintain a clean environment.

A vacuum blower can further optimize the system by extracting air from the unit, ensuring minimal airflow disruption through the discharged material and improving overall efficiency.

Key Features of the KU Static Separator

- Optimized Airflow Management – Separates material efficiently while reducing excess air release.

- Integrated Guide Plate – KU 4000, 6000, and 10000 models include a guide plate for directing airflow toward the air outlet.

- Customizable Filtration Setup – Optional transitions for easy pipe system connection if additional dust filtration is required.

- Seamless Integration – Designed to work with pneumatic conveying systems in industrial applications.

Benefits of Using the KU Static Separator

- Reduces Airflow Disruption – Ensures smooth material discharge with minimal air interference.

- Enhances Dust Control – Can be paired with a filtration system for improved air quality.

- Improves Efficiency – Optimizes pneumatic conveying performance for consistent operation.

- Flexible Installation – Can be adapted to different conveying system setups.

- Durable & Low Maintenance – Built for long-lasting performance with minimal upkeep.

Downloads

Download brochures, manuals, data sheets, and spare parts lists for the KU Separator.

KU Separator Model Comparison

Compare available KU Separator models. Visit the downloads section for additional technical information.

| KU 4000 | KU 6000 | KU 10000 | KU14000 | KU20000 | KU30000 | KU4000 | |

|---|---|---|---|---|---|---|---|

| Airflow [m³/h] | 3500 | 4800 | 8500 | 11200 | 16000 | 24000 | 32000 |

| Material [t/h] | 2.1 | 2.9 | 5.1 | 6.7 | 9.6 | 14.4 | 19.2 |

| Weight [kg] | 85 | 108 | 220 | 750 | 750 | 900 | 1200 |

We recommend selecting a KU model with approximately 80% of the listed airflow capacity. These airflow values represent normal to high operating conditions.