Applications

Filter

By System

By Industry

By Product

Solutions for conveying of granules with low weight, to one or multiple destinations, and in low or high capacity installations.

Automate the movement of injection moulded components using powerful and space-saving pneumatic systems.

RVS separator systems are perfect for larger systems that demand maximum suction power.

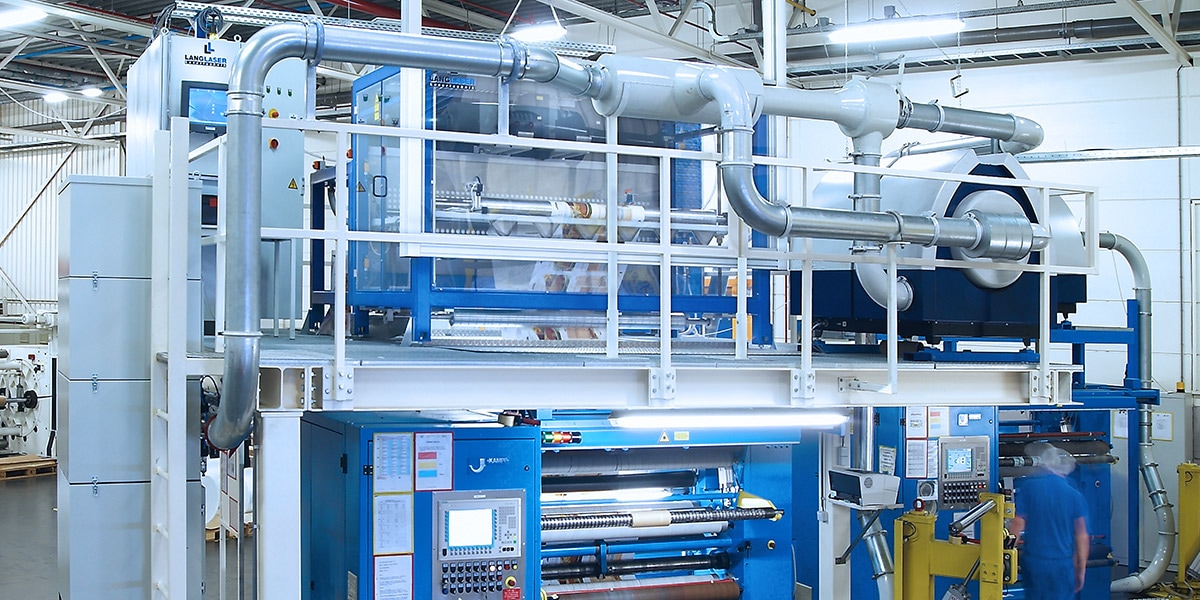

Trim removal systems designed to meet the demands of high-speed production lines.

Remove unnecessary dust and light impurities from re-processed material or plastic pellets with a reliable plastic regrind dust collector system.

Streamline your die-cutting process with a compact, efficient solution for handling skeleton and punch waste.

Efficient and low-maintenance trim handling systems for continuous production lines.

Efficiently move blow molded bottles and products with Kongskilde’s Inline Venturi system.

Efficient flash line transport and reject handling using a customizable Kongskilde pneumatic rejection system.

Boost your recycling efficiency with pneumatic conveying and dedusting solutions tailored for post-consumer and post-industrial recycling operations.

Boost material quality and improve the reusability of plastics with efficient, air-powered separation solutions.

Venturi-based waste extraction systems for efficient transport of tissue logs or cookies in high-speed productions.

Trim extraction systems designed to efficiently handle off-cuts in high-speed productions.

Material Handling Products

Kongskilde products are designed to streamline production applications, free up space, and enhance safety in your production area.