The MultiDicer – Compact, Powerful Waste Reduction

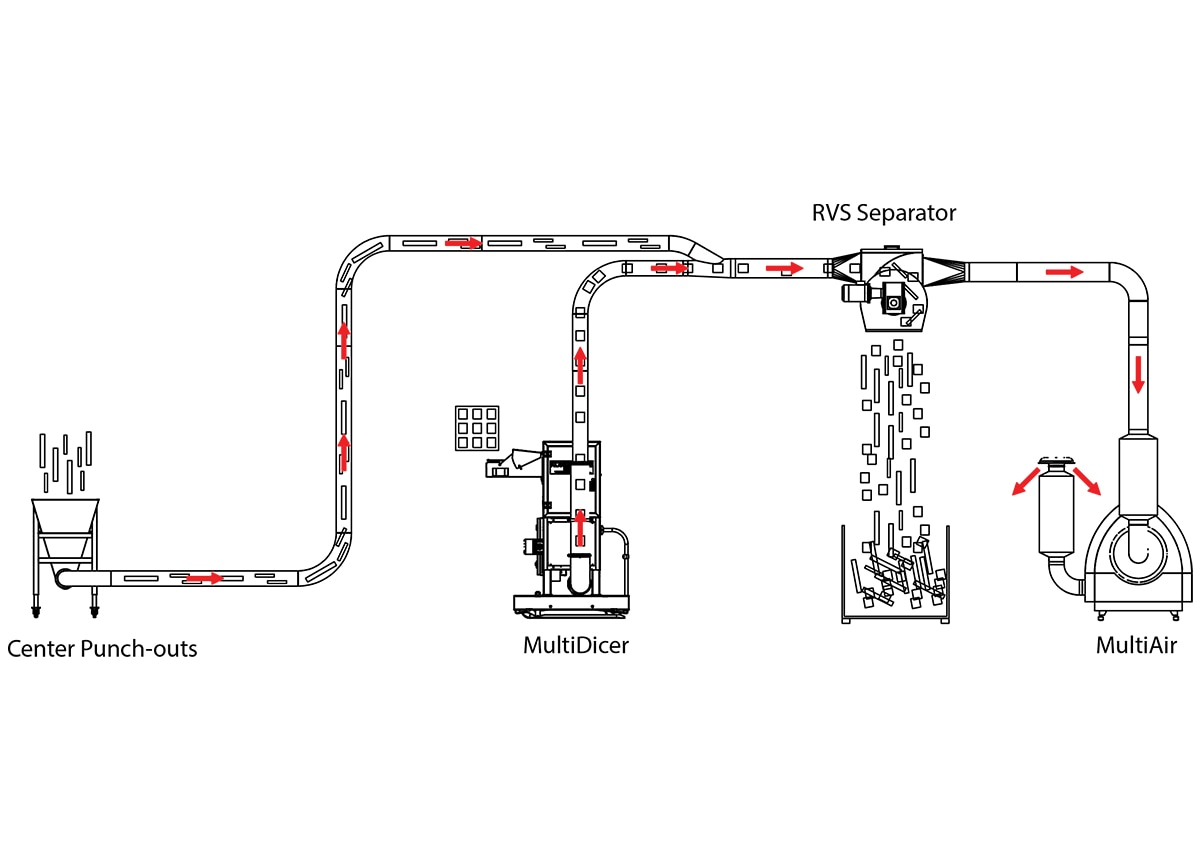

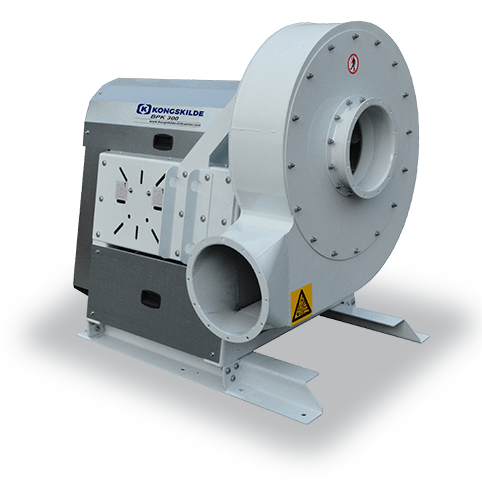

Kongskilde’s MultiDicer is purpose-built to downsize waste from skeleton dies and die cut punchers, making pneumatic transport more efficient. By reducing large cardboard or carton board skeletons and skeleton punches at the source, the MultiDicer allows for smaller diameter conveying pipes—saving valuable production space and lowering energy usage.

Less air volume means reduced power consumption and fewer disruptions to your HVAC system, as only minimal conditioned air is removed. This setup also allows operators to stay focused on production instead of emptying waste bins—improving productivity and minimizing downtime.

Pneumatic Skeleton Waste Solutions in Action

Watch how our system transfers skeleton puncher waste directly from the die cutter to a compactor. Designed to reduce floor clutter, manual labor, and airborne dust, this pneumatic conveying solution is ideal for high-speed production environments.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

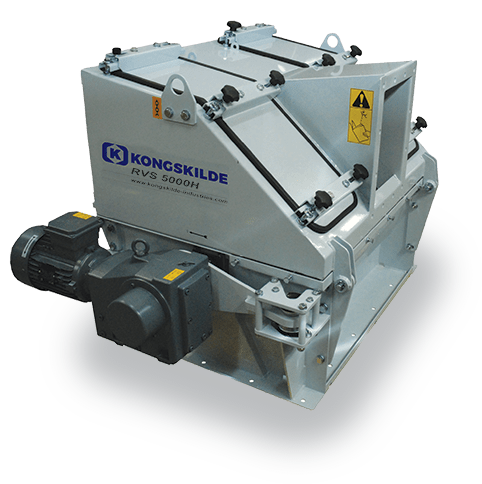

Separation and Shredding of Waste in a Cardboard Packaging Production – Poland

A manufacturer needed a more efficient, safer, and cleaner way to shred and transport cardboard waste while reducing energy use.