The Challenge: Ensuring Clean, High-Quality Plastic Regrind

The plant processes large volumes of plastic regrind from various sources, including milling, mixing, and big bag discharge. However, high dust content in the reprocessed material—often up to 10%—created several operational challenges:

- Dust contamination reduced the quality of recycled flakes and granulate

- Manual cleaning steps slowed production and reduced overall throughput

- Light fractions and dust were difficult to remove, even with traditional methods

- High dust levels created health, safety, and equipment durability concerns

- Customers demanded cleaner recycled material suitable for higher-end applications

To meet quality expectations and support business growth, the plant required a compact and efficient dedusting solution that could reliably clean regrind across PE and PET material streams.

The Facts: Material & System Specifications

Material Details

- Material: PE dust, PET dust

- Bulk density: 450–710 kg/m³

- Flake size: Max 15 × 15 mm

- Regrind percentage: 100% reprocessed material

- Dust content: Up to 10%

- Throughput: Up to 1000 kg/h

System Requirements

- Max conveying distance: 10 m

- Max number of bends: 3

- Ability to handle regrind from multiple upstream sources

- Reliable separation of flakes, fines, and dust

- Continuous operation with minimal maintenance

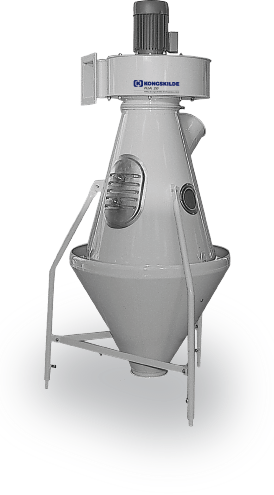

The Solution: A Complete AirWash System for Regrind Dedusting

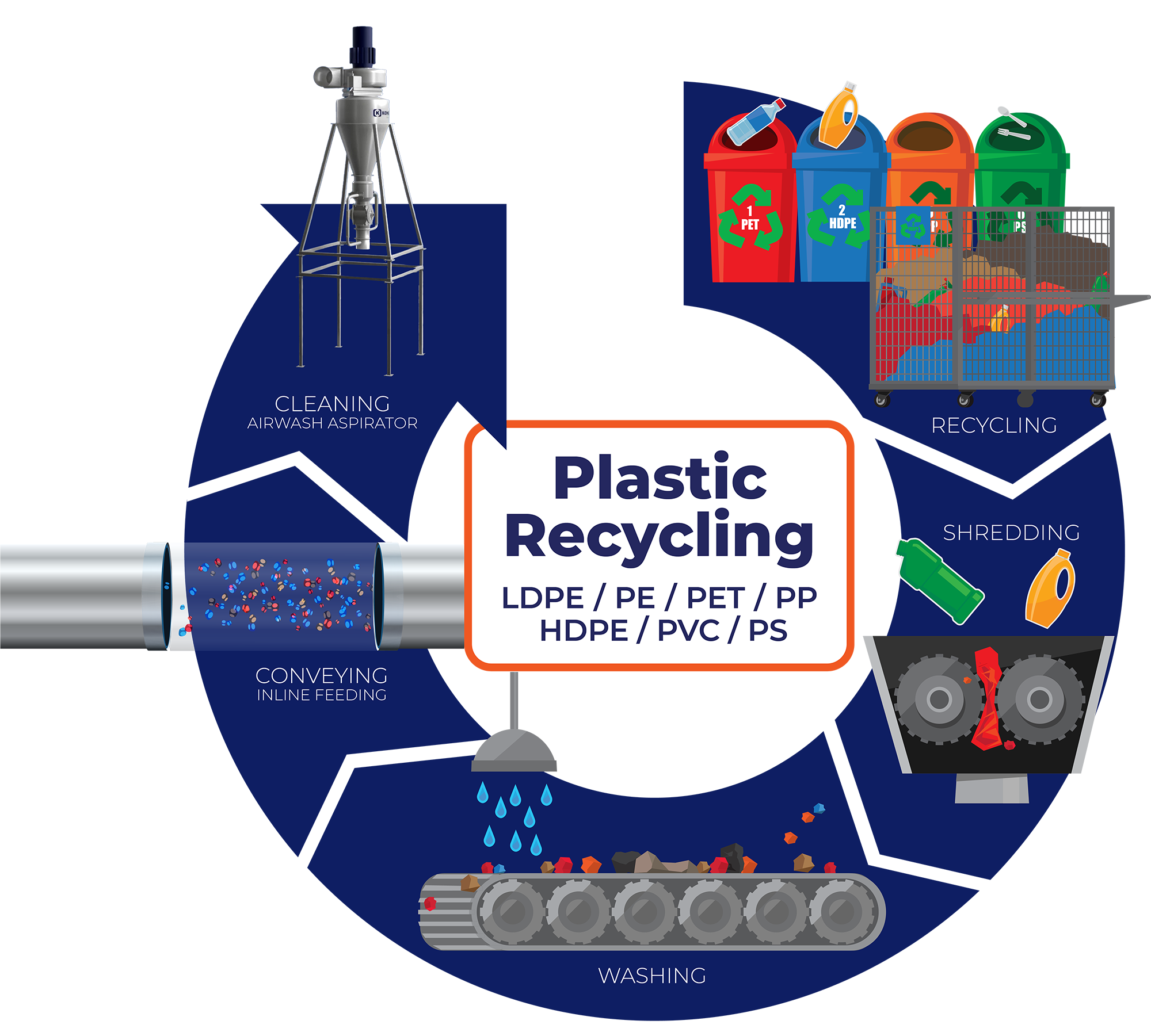

Kongskilde installed a fully integrated AirWash system, designed to provide thorough separation and dedusting of plastic regrind using a combination of pneumatic conveying, dust extraction, and a one-step cleaning process.

How the AirWash System Works

- Regrind is directly collected from mills, mixers, or big bags and conveyed directly into the AirWash system.

- Inside the AirWash, the material undergoes a multi-stage cleaning process:

- Cyclone separation

- Cascade airflow cleaning

- Zigzag vacuum nozzles for precision dedusting

- Clean flakes discharge through a sealed rotary valve and are stored in a big bag or conveyed further.

- Dust and fines are pulled through the fan suction line into a bag filter, where material drops into 200-liter collection drums.

- The system functions as an efficient dedusting system, improving overall material quality without degrading the regrind.

This integrated setup ensures consistent, high-quality regrind output suitable for demanding recycling applications.

Advantages & Benefits: Cleaner Material, Higher Output, Better Working Conditions

Increased Production Efficiency

- The AirWash system enables continuous cleaning and conveying, maximizing throughput and minimizing bottlenecks—especially critical in high-volume recycling operations

Higher-Quality Regranulate

- Clean, dedusted flakes produce better-quality regranulate

- Supports production of more consistent, high-performance end products

- Improves marketability and customer satisfaction

Stronger Customer Retention and Growth

- Reliable supply of clean plastic regrind allows the plant to serve demanding customers and expand into higher-value market segments

Resource Optimization

- More material can be recovered and reused, improving overall recycling efficiency and reducing waste

Cleaner, Safer Working Environment

- The AirWash significantly reduces airborne dust

- Enhances employee well-being

- Reduces accidents and equipment wear

- Improves overall factory cleanliness

Lower Maintenance Costs

- Cleaner regrind leads to less equipment contamination and fewer maintenance interventions, resulting in long-term cost savings

Easy, Flexible Installation

- Modular components allow seamless integration into existing production lines, enabling quick setup and future scalability

The AirWash aspiration system is an effective solution for separating and cleaning plastic pellets and granules for recycling. Unwanted fines and dust are removed and collected, ultimately improving the quality of reusable materials.

Regrind is easily fed directly into the AirWash, creating a smooth, operator-friendly workflow from collection to cleaning.

Download the full case study:

Explore Kongskilde Solutions for Plastic Regrind Cleaning

Kongskilde provides complete systems for plastic regrind cleaning, dedusting, and conveying—helping manufacturers reduce waste, improve product quality, and maximize the value of recycled resin.

Improve Your Plastic Regrind Cleaning and Dedusting Efficiency

Ready to produce cleaner granulate, increase throughput, and improve workplace safety? Don’t hesitate to ask how we can help.