Mechanical Conveyors

Grain Cannons – DGC

The Kongskilde DGC grain cannon is the perfect solution for grain conveying applications that require flexibility, mobility, and stability.

Designed with an integrated hopper and foot-mounted motor, the DGC grain cannon is mounted on a sturdy two-wheeled frame, making it easy to adjust the outlet height and move the cannon as needed. This portable grain cannon offers flexibility and convenience, allowing it to be positioned at various angles, from 25 to 45-degree inclination, to suit different conveying requirements.

DGC Grain Cannons

The DGC grain cannon provides a cost-effective and highly mobile solution for efficient grain handling. The DGC grain cannon delivers with adjustable height and easy mobility, making it ideal for different applications in agricultural operations.

Key Features of DGC Grain Cannons:

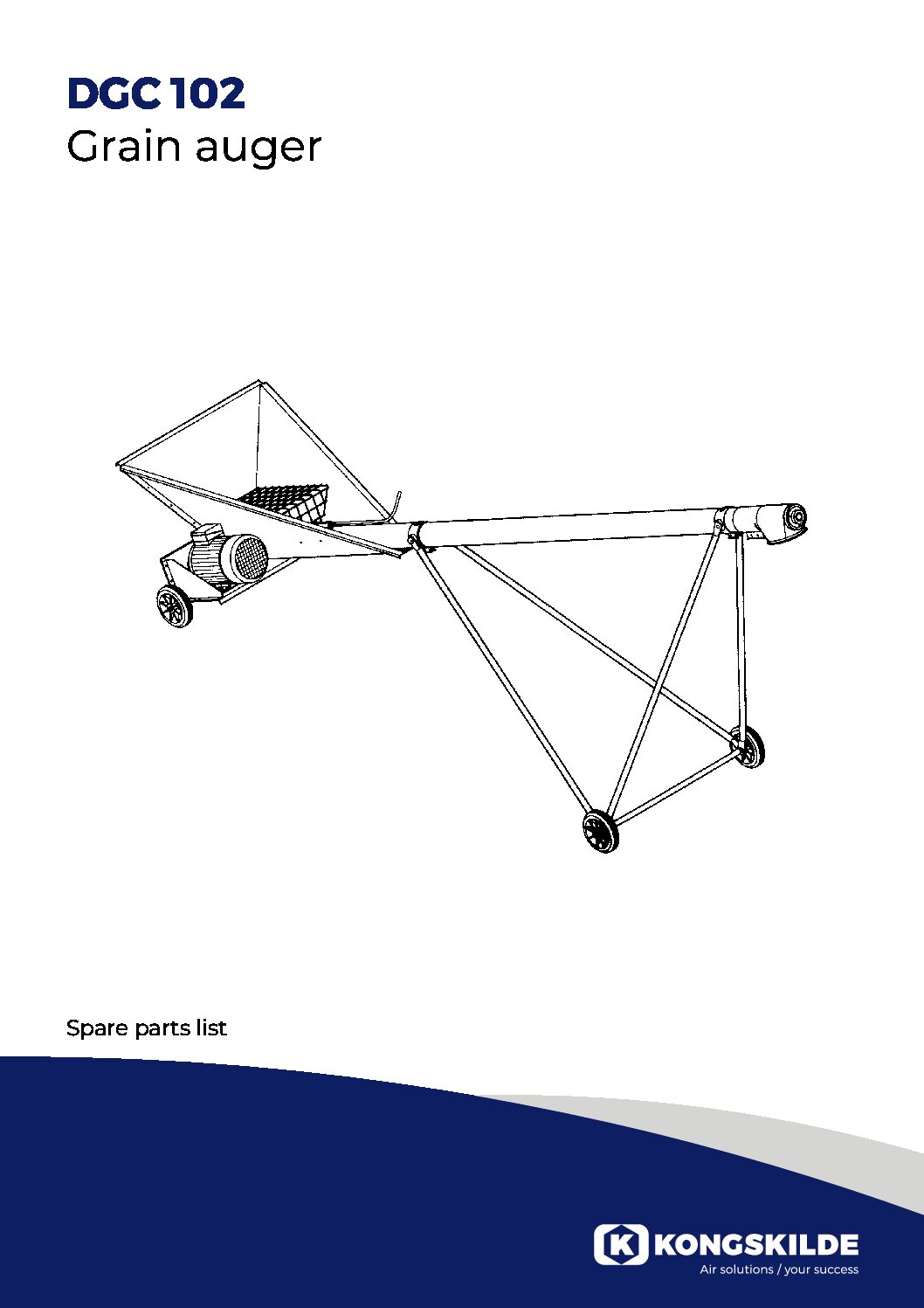

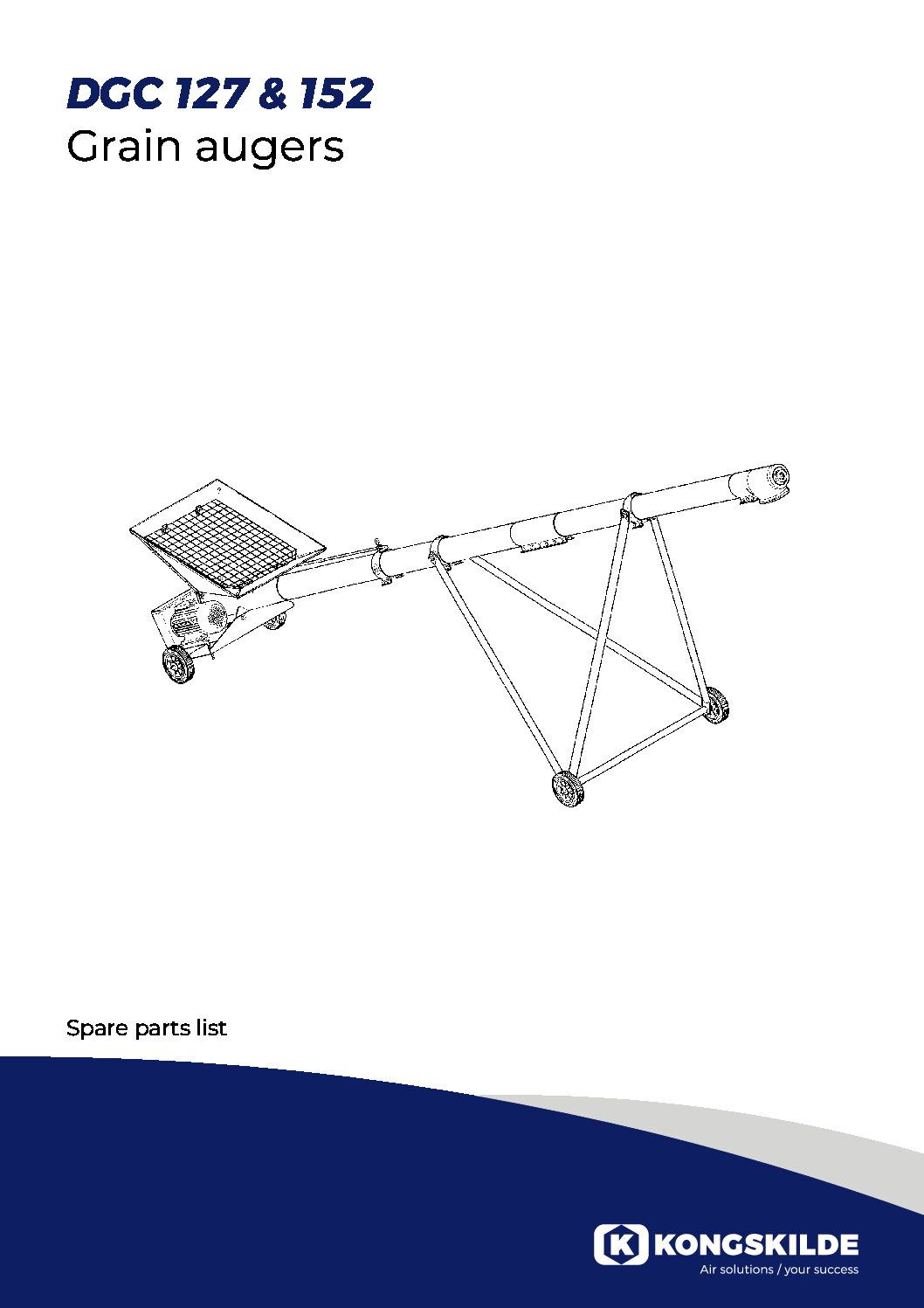

- Three Available Models: Choose from DGC 102, DGC 127, and DGC 152 to meet your specific grain conveying needs.

- Integrated Hopper and Belt Drive: Features an inlet hopper with a belt drive system and motor mounted at the bottom inlet end for efficient operation.

- Mobile Design: Mounted on a two-wheeled stand for easy movement and stability, allowing for quick adjustments to the outlet height and positioning.

- Capacity: Supports 25-degree inclined conveying with capacities of up to 35 tonnes per hour.

- Max Length: Available with an overall maximum length of 6 meters, providing flexibility for different setups.

Downloads

Download brochures, manuals, and spare parts lists for the DGC grain cannons.

DGC Grain Cannons Applications

The DGC grain cannon is particularly suited for applications requiring mobility and easy positioning. Its stable, wheeled design makes it ideal for grain handling in storage facilities, grain pits, and other agricultural environments where flexible, on-the-go grain conveying is needed. The ability to adjust from horizontal to vertical positions adds to its versatility, making it a valuable tool in any grain handling operation.