Energy Savings With the MultiAir

Variable-speed drive control using a frequency converter

Achieve precise speed control on your blower with a built-in frequency converter. Ramp speeds up or down to match your needs, saving energy by only using what’s necessary.

The Benefits of the Frequency Converter

Controlled Starting Current. When an AC motor is started “across the line,” it can take up to as much as 7-8 times the motor’s full-load current to start the motor and load. This current flexes the motor windings and generates heat, which will, over time, reduce the longevity of the motor. A variable frequency drive starts a motor at zero frequency and voltage. As the frequency and voltage “build,” it “magnetizes” the motor windings, which typically takes 50-70% of the motor full-load current. Additional current above this level is dependent upon the connected load, the acceleration rate and the speed being accelerated, too. This extends motor life!

Reduced Power Line Disturbances. Starting an AC motor across the line, and the subsequent demand for 300-600 % the motor full-load current, places an enormous drain on the power distribution system connected to the motor. When the supply voltage sags, depending on the size of the motor and the capacity of the distribution system, the voltage sags can cause sensitive equipment connected to the same distribution system to trip offline due to the low voltage. Items such as computers, sensors, proximity switches, and contactors are voltage sensitive and, when subjected to a large AC motor line started nearby, can drop out. Using variable frequency eliminates this voltage sag since the motor is started at zero voltage and ramped up.

Lower Power Demand on Start. If power is proportional to current-times-voltage, then the power needed to start an AC motor across the line is significantly higher than with a variable frequency drive. This will be true only at the start-up. The primary issue is that some electrical distribution systems might be at their limit during specific times of day, usually considered “Peak Hours.” When industrial customers start their motors during these peak hours of electrical consumption, it is not uncommon for the customer to be stung with charges for surges in power during peak periods. These demand factors would not be an issue with a frequency converter.

Adjustable Torque Limit. The use of a frequency converter can protect machinery from damage because the amount of torque being applied can be controlled accurately, ie in the case of a conveyor jam.

Adjustable Operating Speed. Unlike the traditional stop-and-go motor, the use of a frequency converter allows starting at reduced speed and allows remote adjustment of speed by a programmable controller or process controller. Control, in an industrial sense, is always a big bonus for production.

Controlled Acceleration. A blower with FC motor starts at zero speed and accelerates smoothly on a customer-adjustable ramp. Conversely, an AC motor that started “across the line” triggers higher mechanical shock loads both for the motor and mechanically connected load. This shock will, over time, increase the wear and tear not only on the connected load but the AC motor as well. Applications that include easy-to-tip products, such as bottling lines, greatly benefit from a slow ramp-up in power which allows the conveyor belt to smoothly speed up rather than an abrupt jerk to full power.

Controlled Stopping. Controlled stopping can be important to reduce mechanical wear and tear.

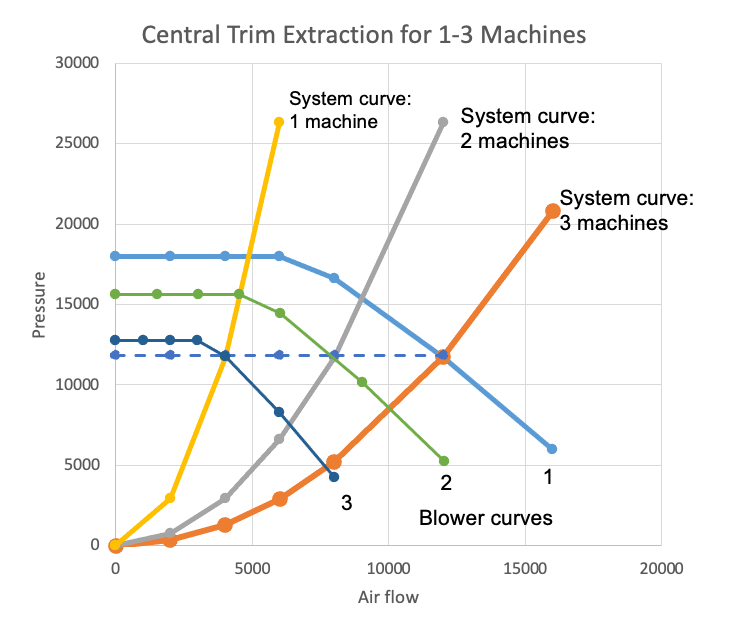

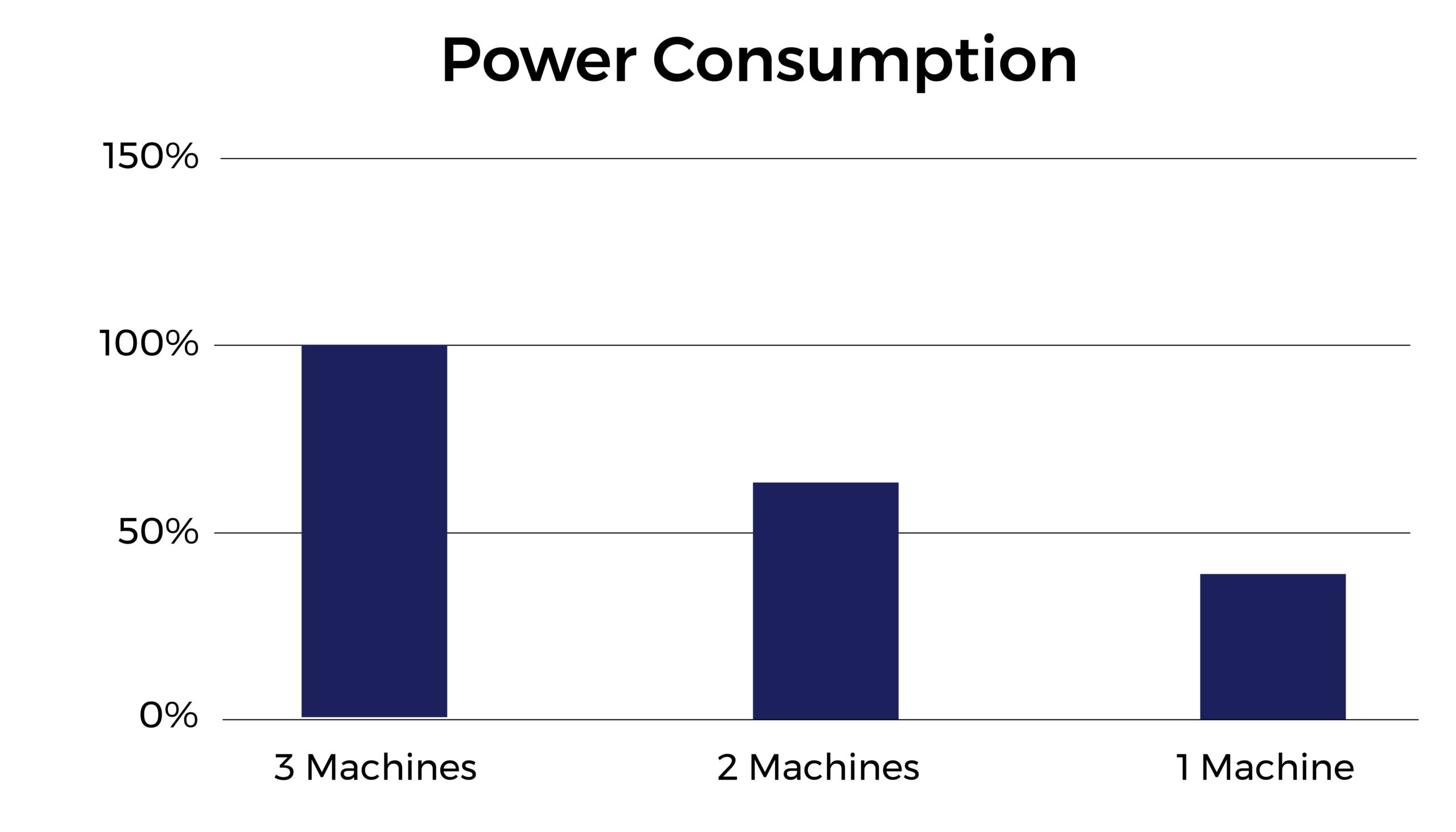

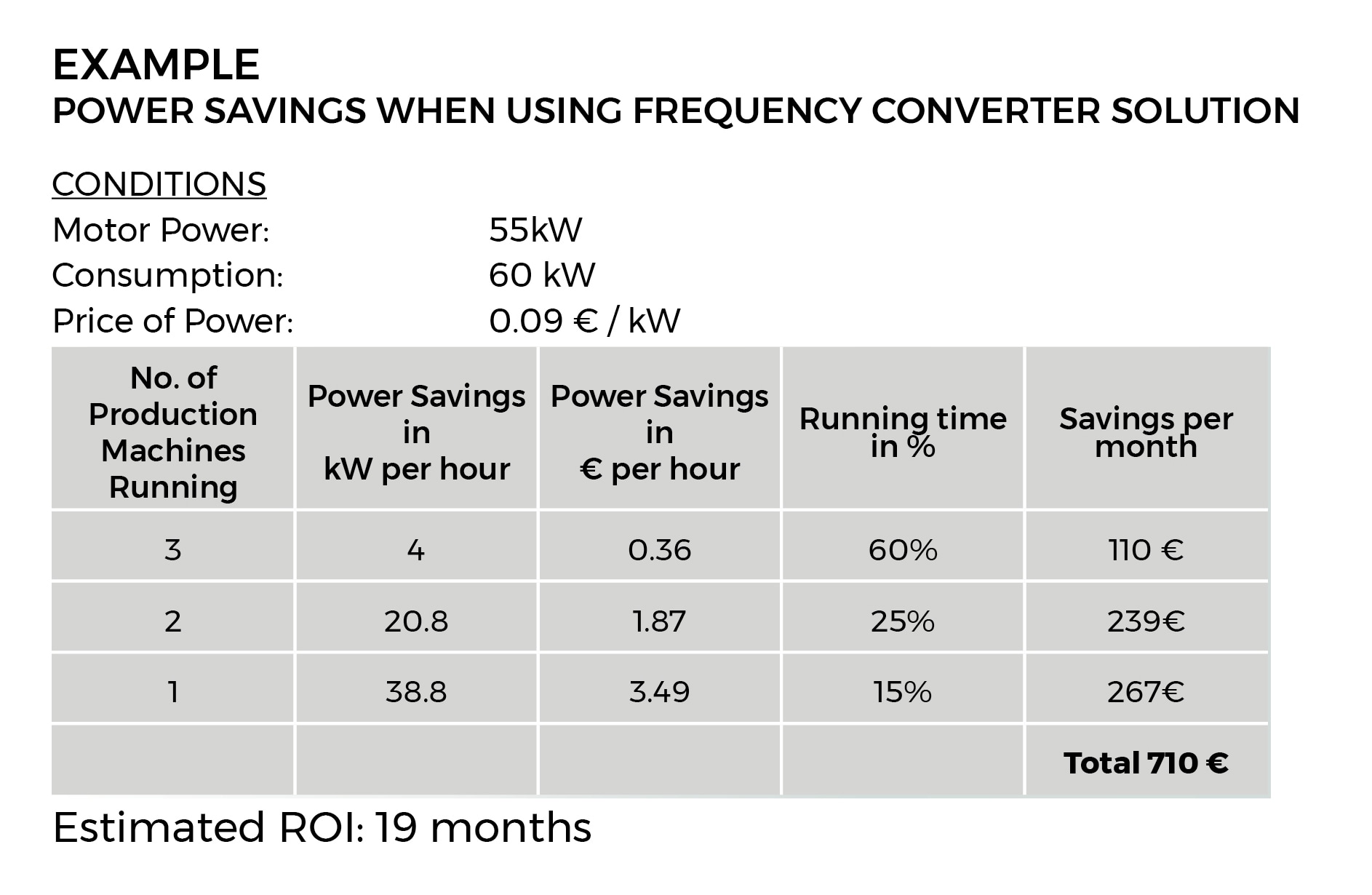

Energy Savings. Blowers operated with a frequency converter will reduce energy consumption. A variable frequency drive controlling a blower motor that usually runs less than full speed can substantially reduce energy consumption over a motor running at a constant speed for the same period. Because this benefit varies depending on system variables, it is important to calculate benefits for each application before calculating the shortened payback period.

All manufacturers may potentially reduce their energy consumption by an average of 50%.

To learn more about the potential for energy savings in your pneumatic conveying solution with an FC blower, contact us today!