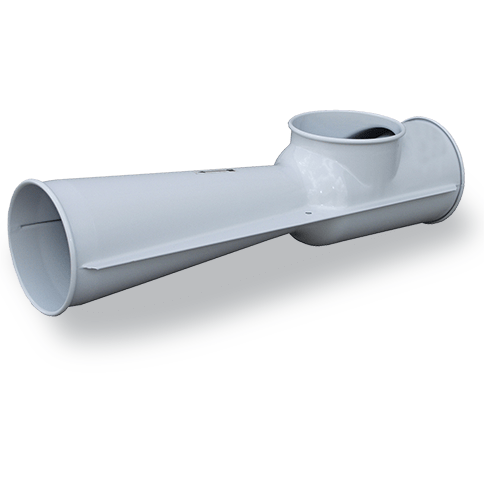

Material Feeders

Kongskilde’s material feeders and feeder systems are engineered to minimize air losses during product introduction into pressurized conveying systems. Designed for versatility, these feeders efficiently handle a variety of materials, including granulates, pellets, flakes, and small molded products, making them ideal for diverse industrial applications.

How Kongskilde Material Feeders Work

Kongskilde material feeders work by introducing products into pressurized pneumatic conveying systems. The design focuses on maintaining the integrity and continuous flow of materials, thereby reducing air loss and ensuring efficient transport from the feeding point to the destination.

Benefits of Kongskilde Material Feeders

- Reduced Air Loss: Optimizes system efficiency by minimizing air leakage during material transfer.

- Versatility: Capable of handling a range of materials from granules to small molded products.

- Enhanced Productivity: Increases throughput by ensuring consistent and reliable material feeding.

- Low Maintenance: Designed for durability and ease of use, reducing downtime and maintenance costs.

FAQ: Material Feeder System

What types of materials can Kongskilde material feeders handle?

Kongskilde material feeders are versatile and can handle a wide array of materials, including granules, pellets, flakes, and small molded products. They are suitable for various industries such as plastics manufacturing.

How do Kongskilde material feeders integrate with existing systems?

Kongskilde material feeders are designed to seamlessly integrate with existing pneumatic conveying systems. They can be easily installed and adjusted to match the specific needs of any production line, enhancing overall system compatibility and functionality.

Are Kongskilde material feeders suitable for high-demand applications?

Yes, Kongskilde material feeders are built to withstand the demands of high-volume industrial environments. Their robust design ensures reliable performance and continuous operation, even under strenuous conditions.

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.