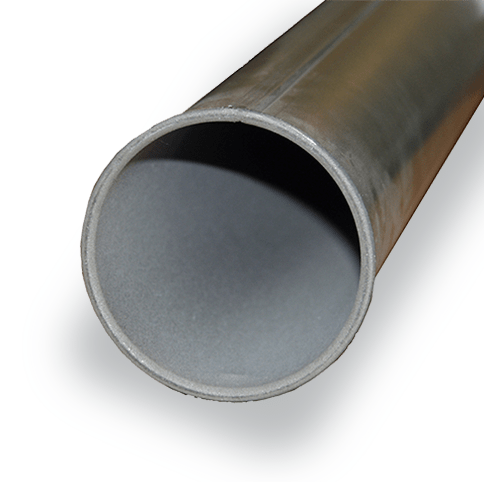

Conveying Lines – Pipes

Coated Pipes

Anti-sticky pipes for conveying adhesive material through a pneumatic system

Kongskilde’s coated pipes are engineered with a specialized anti-stick pipe coating that enables the smooth conveying of adhesive materials through pneumatic systems.

Unlike standard transport pipes, which can experience material buildup, Kongskilde’s coated pipes provide an effective solution to prevent blockages and minimize maintenance. This coated pipe system is ideal for industries that handle sticky or adhesive materials, ensuring efficient and continuous flow without the risk of clogging.

Key Features of Kongskilde Coated Pipes

Designed to enhance productivity and streamline material handling, Kongskilde’s coated pipe system includes specialized features that address the unique challenges of transporting adhesive materials:

- Seamless Integration: Easily integrates into existing pneumatic conveying systems, allowing for efficient upgrades or system enhancements.

- Anti-Stick Pipe Coating: Reduces material adhesion to the inner surface, ensuring a smooth, uninterrupted flow of adhesive or sticky substances.

- Durable Construction: Built to withstand the demands of industrial environments, providing long-lasting performance in pneumatic conveying systems.

- Customizable System: Kongskilde offers tailored solutions with coated pipes designed to meet specific requirements for different materials and setups.

Benefits of Using Kongskilde Coated Pipes

Implementing Kongskilde’s coated pipes offers significant advantages for facilities dealing with adhesive materials:

- Reduced Maintenance: The non-stick pipe coating prevents material buildup, minimizing downtime for cleaning and reducing maintenance costs.

- Increased Productivity: Ensures continuous operation without interruptions from blockages, enhancing overall system efficiency.

- Enhanced System Reliability: The coated pipes support consistent material flow, reducing the likelihood of clogging and prolonging equipment life.

- Cost-Effective Solution: By reducing manual cleaning and improving system uptime, coated pipes offer a cost-effective solution for conveying adhesive materials.

- Customized Design: Kongskilde’s coated pipes can be tailored to match specific operational needs, optimizing performance for various materials.

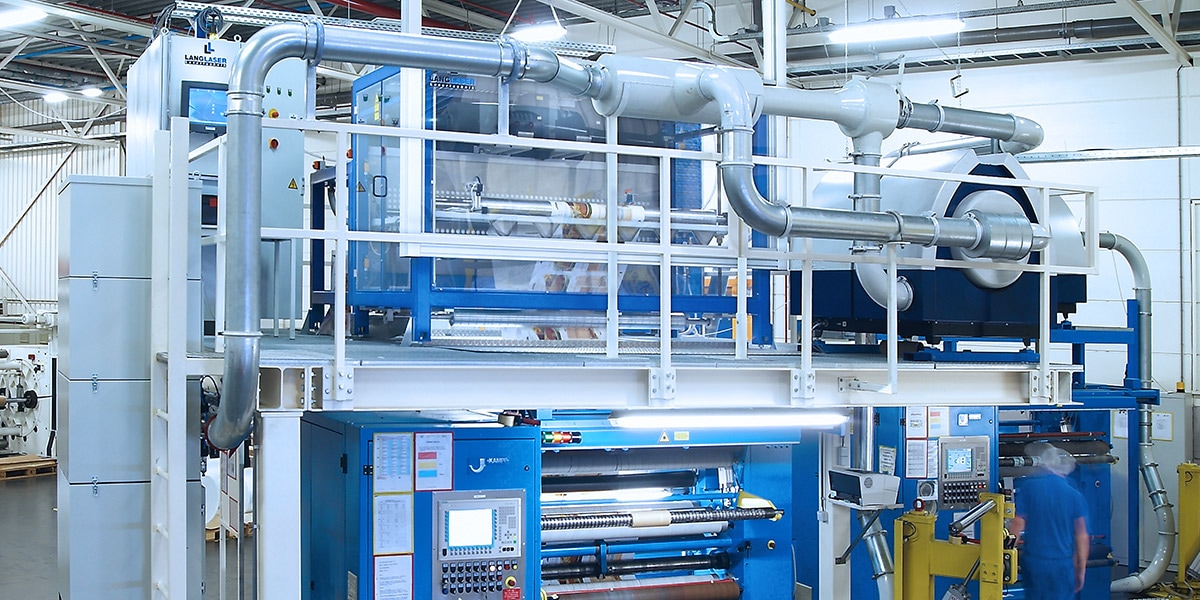

Applications of Coated Pipes in Pneumatic Conveying

Kongskilde’s coated pipes are ideal for a range of industrial applications where adhesive or sticky materials require reliable, non-stick conveying:

- Label Printing Industry: Commonly used to transport adhesive waste materials, such as continuous skeleton webs, within the label printing process. The coated pipe system automatically picks up and conveys adhesive waste to designated discharge points, eliminating the need for manual removal.

- Packaging and Converting: Efficiently transports adhesive remnants and scrap materials generated in packaging and converting operations, reducing production bottlenecks.

- Food and Beverage Processing: Handles sticky ingredients or waste materials, ensuring smooth and sanitary transportation within pneumatic conveying systems.

Coated Pipe Downloads

Download data sheets for Kongskilde’s coated pipes.