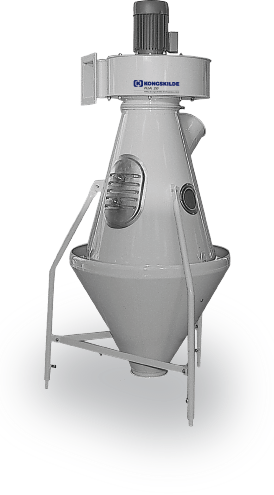

Material Separators

Kongskilde’s industrial separation equipment is expertly designed to remove light impurities or dust from re-processed materials, such as granulated plastics. Essential for recycling processes, our separators ensure that materials are ready for productive reuse, enhancing the quality of the final product.

How Kongskilde Industrial Separators Work

Kongskilde industrial separators utilize advanced technology to efficiently separate light impurities and dust from granulated materials. By creating a dynamic airflow, these systems draw lighter particles away from the denser, reusable materials, ensuring that only clean, pure material passes through for further processing and reuse.

What is the Goal of Material Separation?

Industrial material separation processes are technical procedures used to separate a product from either impurities or other products. Separation may also involve separating dust from re-processed materials.

Most recycled raw materials need to go through a separation process before they can be productively re-used. Material separation is an essential technique for the current industrial economy. An effective material separation process allows you to turn recycled materials into valuable reusable materials. It is important to recycle as much plastic as possible, for both the sake of the environment as well as profit-related reasons for your business.

Separation processes thus serve a multitude of functions, including the purification of materials, recovery of by-products, recycling, and removal of contaminants. Multiple operations can, of course, be combined to achieve the desired end product.

Benefits of Kongskilde Industrial Separation Equipment

- Improved Product Quality: Ensures high purity of materials by effectively removing impurities and dust.

- Increased Efficiency: Streamlines the recycling process by preparing materials more quickly for reuse.

- Cost-Effective: Reduces waste and minimizes the need for additional purification steps, saving on operational costs.

- Versatile Applications: Ideal for a wide range of materials, particularly effective in the plastics and recycling industries.

FAQ: Industrial Separation Equipment

What types of impurities can Kongskilde separation equipment remove?

Kongskilde industrial separators are designed to remove lightweight impurities such as dust, paper, labels, and other fine particles from heavier granulated materials, making them especially useful in plastic recycling and reprocessing.

How does separation equipment benefit the recycling industry?

Separation equipment is crucial in the recycling industry as it enhances the purity of recycled materials, ensuring they are of high quality and suitable for production use. This not only improves the final product but also makes the recycling process more efficient and sustainable.

Can Kongskilde separation equipment handle different material volumes?

Yes, Kongskilde separation equipment can handle a range of material volumes, from small-scale operations to large industrial applications. The systems are scalable and can be customized to meet specific operational needs, ensuring optimal performance across various settings.

Finding the right material separators and industrial recycling machines for your production

We at Kongskilde Industries offer flexible solutions for separating materials which are efficient and easy to install. Since separation processes are often a main part of manufacturing and recycling, they are essential to various industries. To achieve the ideal separation process, it may be necessary to combine different methods to meet your recycling requirements. Reach out to Kongskilde and we can help find the right solution for your production.

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.