The Challenge

This Polish manufacturer is part of a multinational oleo chemical and personal care products company.

- They needed a flexible conveying solution that could provide a fast, safe, and friction-free transport of high-pressure soap granulates from Big Bags directly to silos.

- The conveying solution had to create a dynamic form of transport of the granulates to obtain an adequate material yield. If the soap granules are heated during transport they lose yield and the conveying system must be cleaned more often and thereby increasing the cost price for the soap production.

- The conveying system needs a cooling system or the ability to keep the granulates cool during transport.

- The system must be able to be connected to the latch on the Big Bags to minimize the manpower required to operate the transportation.

The Solution

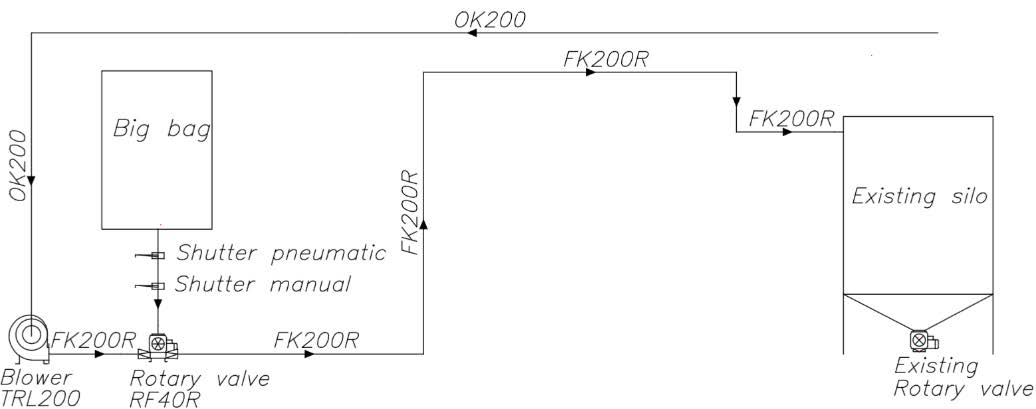

- The solution consists of standard modular components that ensure a conveying system that can be built to fulfill the special requirements and also be flexible for future expansion.

- The solution consists of TRL 200 Blower, RFD 40 Rotary valve, pneumatic and manual shutters, and stainless steel pipes. This secures a fast and friction-free transport of difficult material in the most cost-effective way.

- With this system, the customer gained a solution that contributes to increased productivity with minimal downtime due to maintenance.

The Advantages and Benefits

- High flexibility in Kongskilde’s modular conveying solutions with easy installation and cost-effective upgrading.

- The solution with stainless steel pipes surpasses other conveying systems in terms of safe transport without friction to secure the quality of the soap granulates.

- The low pressure in the Kongskilde system was able to limit the temperature rise in the conveying line thereby minimizing damage to the soap granules being conveyed.

- Less need for maintenance of the pneumatic conveyor solution contributes to lower operating costs.

The Facts

- Material: Soap granulates

- Dimensions: granulate max Ø 8mm, grid max Ø 10mm

- Capacity: 3000 kg/hrs.

- Contents of regrind: 100%

- Bulk density: approx. 1100 kg/m3

- Conveying distance: H: max 15 m. V: max 4 m