The Challenge

Transforming Post-Consumer Plastics into High-Quality Raw Material

AVL wanted to expand its capabilities to include using household plastic waste as a valuable resource for plastic recycling. This required developing an advanced process that could handle the complex and contaminated nature of post-consumer materials while delivering high-quality granulate suitable for new products.

AVL’s goal was not only to maintain its high standards, but also to set a new recycling benchmark by transforming household plastic waste into valuable raw materials for industrial use.

Reliability and precision were essential to achieving this goal. AVL needed a solution that could handle the unique challenges of household plastics and seamlessly integrate with their production flow, such as effectively removing dust and light particle contamination.

The Facts

- Source Material: Household plastic waste and post-consumer packaging

- Material Types: Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS)

- Form: Ground plastic in various particle sizes

The Solution

To address these challenges, AVL turned to Kongskilde Industries. AVL implemented two systems designed to handle complex material separation and conveying needs: Kongskilde’s KIA Aspirators and MultiEvacuators.

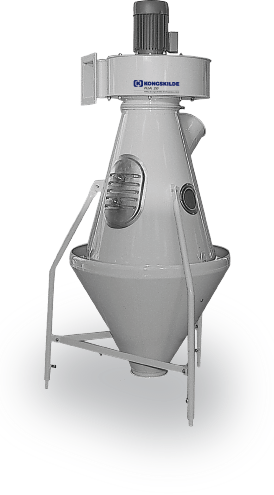

- KIA Aspirators: The aspirators perform a two-stage, cascade separation process to remove even the lightest particles, such as film and foil residues, from the granulated plastic. This ensures that only clean material continues through the next stage of the process.

- MultiEvacuators: After cleaning and sorting with NIR technology, the granules are efficiently transported by high-capacity MultiEvacuators to the next stage, where they are melted to produce high-quality recycled pellets.

According to Bo Jacobsen, AVL’s long-standing relationship with Kongskilde was pivotal.

“Kongskilde has been a trusted partner for many years. Their solutions are reliable, and their team understands our processes. Testing at their technology center helped us identify the optimal solution for our needs.”

The Advantages and Benefits

Since integrating Kongskilde’s solutions, AVL has achieved significant improvements in its recycling operations.

- Enhanced Product Quality: The double-loop aspirator system ensures exceptionally clean granulate, improving the quality of the final recycled pellets.

- Increased Efficiency: Reliable equipment reduces downtime and interruptions, allowing for a stable and efficient production flow.

- Sustainable Output: The ability to produce high-quality pellets supports AVL’s mission to promote the use of recycled materials in new plastic products.

AVL now provides recycled plastic that meets strict industry standards and can be used multiple times. They are committed to pushing the boundaries of plastic recycling and ensuring that recycled plastic becomes the standard for all new plastic products, even in areas such as food packaging.

Effective separation is key to high-quality recycling. By removing dust, film, and other contaminants, separation systems help transform plastic waste into clean, reusable material that meets industry standards.

The MultiEvacuator ensures fast, gentle, and reliable transport of cleaned granules to the next stage in AVL’s recycling process while maintaining throughput and product integrity.

The KIA Aspirator removes dust, film, and light contaminants from granulated household plastics, supporting AVL’s ability to produce high-purity recycled pellets.

Download the full case study:

Featured Products

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.