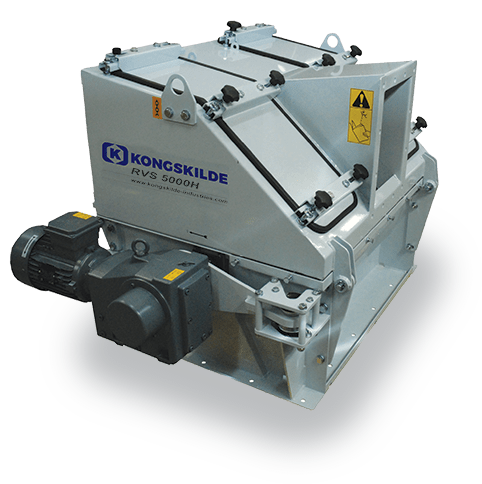

Air / Material Separators

Kongskilde separators are strategically positioned at the discharge end of conveying systems, such as stationary compactors, balers, or containers, ensuring efficient material separation from the conveying air flow. This placement allows for precise extraction of materials, enhancing the overall efficiency and cleanliness of the operation.

By choosing Kongskilde separators, businesses benefit from a reliable separation process that improves system functionality and material handling.

How Industrial Material Separators Work

We have various innovative solutions available to efficiently and easily convey trim. At Kongskilde Industries, we offer cost-effective solutions for handling trim with low maintenance and labor costs. Our systems feature an exceptionally quiet design and modern hardware.

Enhancing Efficiency with Industrial Separators

Kongskilde industrial material separators offer several key advantages that enhance both the productivity and sustainability of manufacturing processes:

- Enhanced Product Purity: Industrial material separators efficiently remove contaminants and impurities, ensuring higher quality and purity of the final product.

- Increased Efficiency: By automating the sorting and separation process, these systems reduce manual labor and streamline production lines.

- Reduced Waste: Separators help minimize waste by accurately sorting usable materials from scrap, leading to more sustainable operations.

- Cost Savings: Improved material handling and reduced contamination lead to lower operational costs and less downtime for maintenance.

FAQ: Industrial Material Separators

What are industrial separation systems?

Industrial separation systems are specialized equipment used to sort and separate different materials based on specific characteristics like size, density, or chemical composition. These systems are crucial in various industries, including recycling, pharmaceuticals, blow molding productions, and food packaging, to ensure product purity and streamline production processes.

How do industrial separation systems improve manufacturing efficiency?

Industrial separation systems enhance manufacturing efficiency by automating the process of sorting raw materials or finished products. This automation reduces labor costs, minimizes errors, speeds up production, and ensures consistent quality in the output, ultimately increasing overall productivity.

What types of materials can be processed using industrial separation systems?

Industrial separation systems can process a wide range of materials. They are versatile enough to handle different forms of waste, raw materials, and by-products in industries such as blow moulding, packaging, film production, converting, and waste management.

Can industrial separation systems be customized for specific applications?

Yes, industrial separation systems can be customized to meet specific operational needs. Manufacturers can adjust the size, configuration, and separation technology to optimize performance for particular materials or environmental conditions, ensuring the system is perfectly suited for the application.

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.