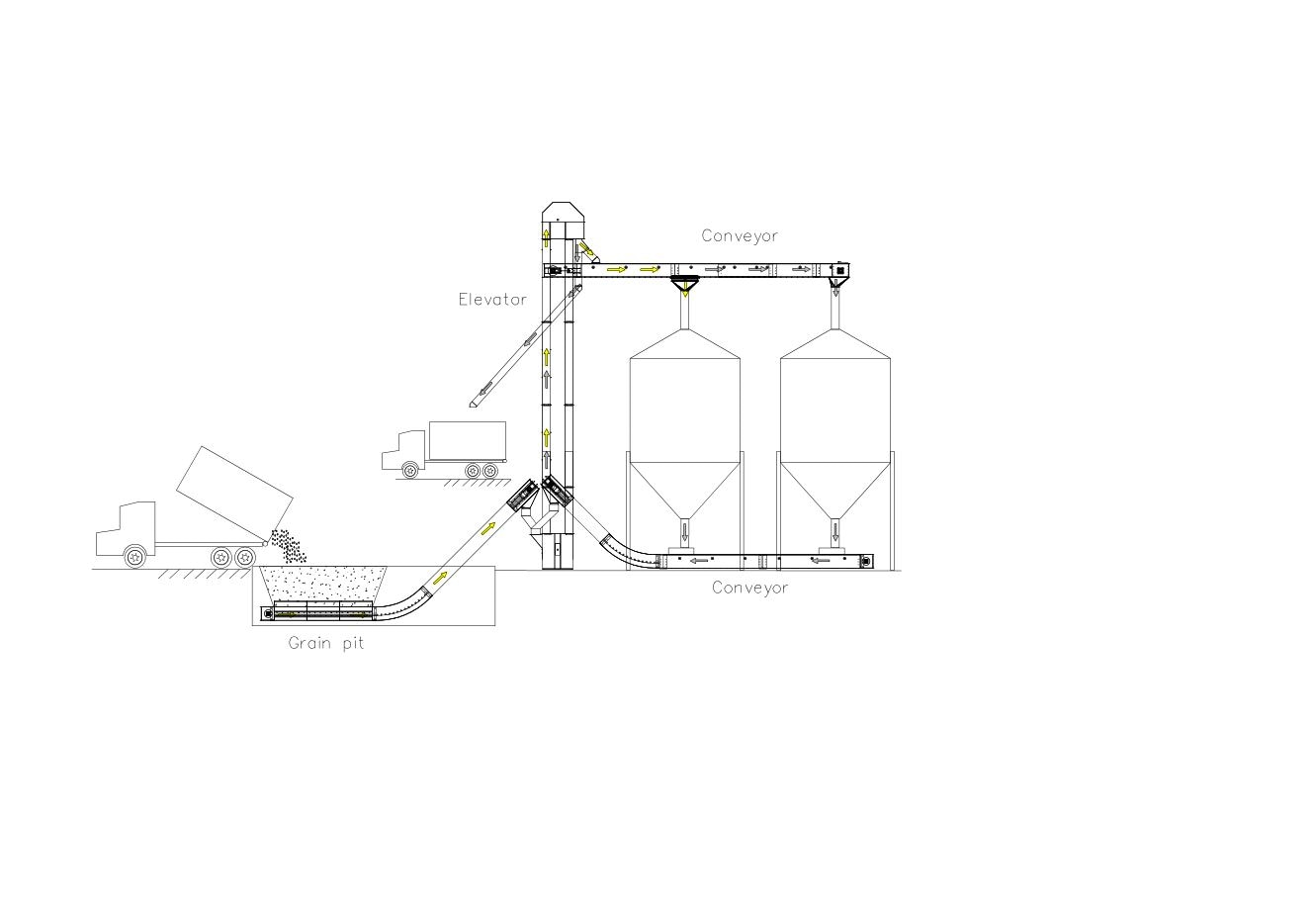

Mechanically Filling and Emptying System for Hopper Silos

A high capacity mechanical system can effectively fill and empty bottom hopper silos.

Filling and Emptying System for Hopper Silos

A high capacity mechanical system can fill and empty bottom hopper silos.

The grain pit can either be built in the ground or installed on the ground. The conveyor from the pit to the elevator is an angle conveyor which feeds into the bucket elevator. The bucket elevator then lifts the grain to a chain conveyor on top of the silos, hereby conveying the grain horizontally into the filling points on top of the silos.

When emptying the silos, an angle conveyor is placed below the bottom outlet of the silos.

The solution can be extended to service more silos.

An example: The angle conveyor feeds the grain into the bucket elevator which in turn lifts the grain to be discharged into a truck or feeds into a conveyor system transporting the grain onto further processing.

Businesses We Serve

Whether your business deals in organic or conventional farming, Kongskilde has a solution designed to optimize your processes and production.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

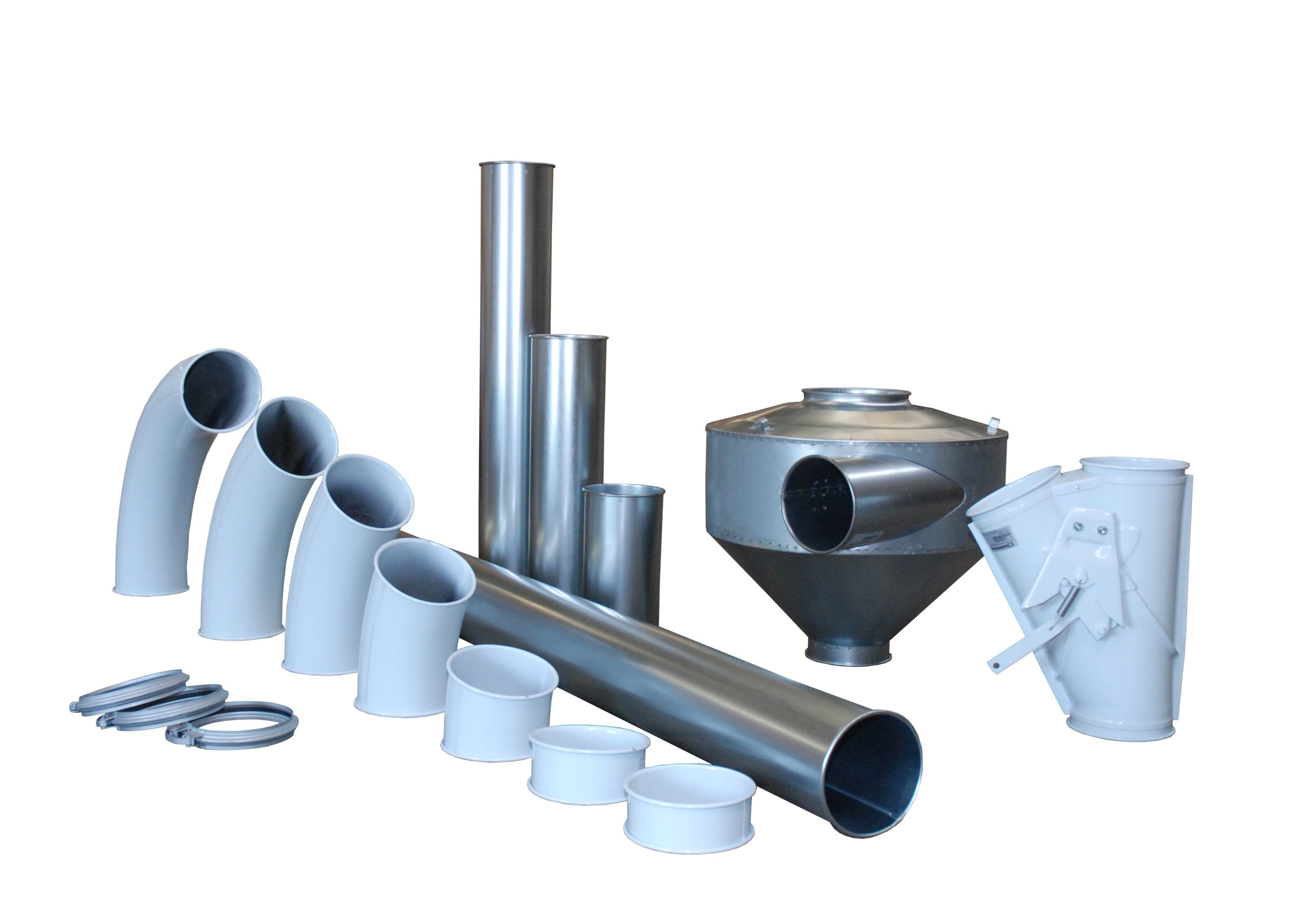

Related Products

Designed for maximum flexibility, reliability, and quality, Kongskilde’s portfolio of complementary products offers additional customization for our world-class pneumatic systems.