Mechanical Conveyors

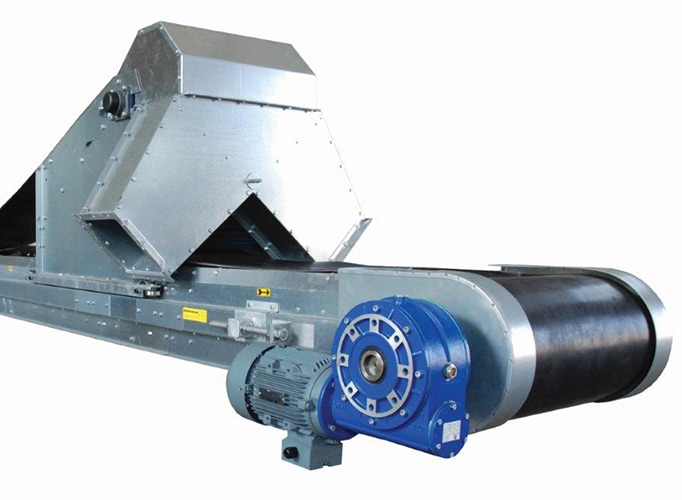

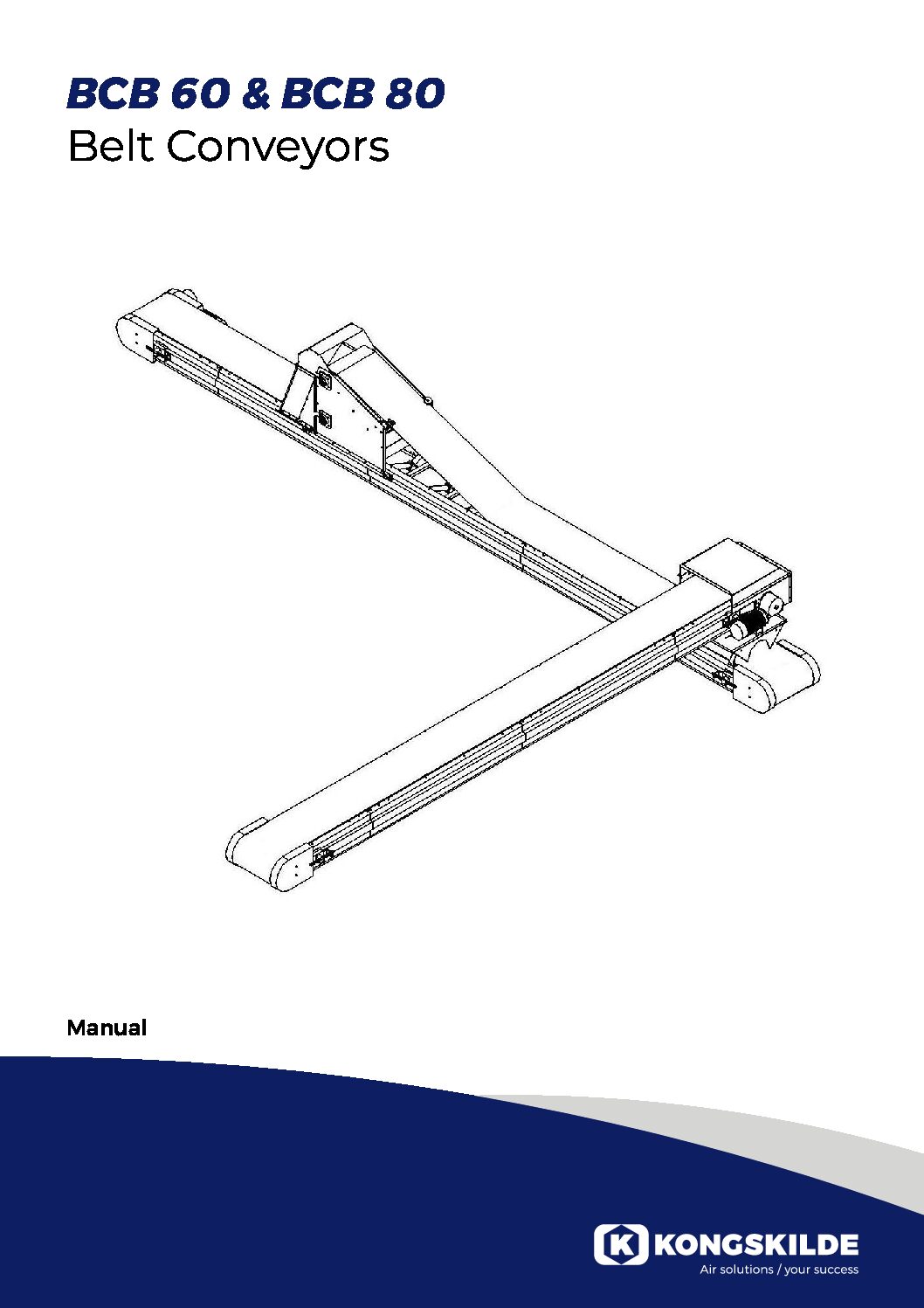

Belt Conveyors – BCB

The Kongskilde BCB belt conveyors offer a versatile and efficient solution for gentle, self-cleaning horizontal grain conveying in environments where minimal power consumption, cleanliness, and flexibility are essential. Equipped with a V-shaped rubber belt, these conveyors ensure smooth handling of grain, rapeseed, and other crops, with no impact on the kernels. This design preserves the quality of the grain and minimizes the risk of contamination.

With conveying capacities ranging from 60 to 80 tons per hour, the BCB series is perfect for operations requiring reliable and gentle grain conveying.

Efficient Grain Handling for Horizontal or Inclined Conveying

The BCB grain belt conveyors are designed for both horizontal and inclined grain conveying solutions, supporting an incline of up to 15°. They offer a maximum capacity of up to 80 t/h over distances of up to 100 meters. When conveying grain at an incline, capacity decreases slightly, but the system remains highly efficient. The self-cleaning nature of the belt makes it an ideal choice for agricultural environments where hygiene and minimal contamination are priorities.

Benefits of BCB Belt Conveyors:

- Modular Design: Offers flexible grain handling solutions with interchangeable standard components.

- Low Energy Consumption: Energy-efficient operation, reducing overall costs.

- Self-Cleaning Design: Reduces spillage and contamination risks.

- Outdoor Durability: Galvanized models are built for outdoor installations, resistant to harsh conditions.

- Versatile Conveying: Supports one-way or two-way conveying for added flexibility.

- Infinite Discharge Points: Allows for customizable discharge points along the length of the conveyor.

Optional Accessories for Enhanced Functionality

- Movable Discharge Unit: Can be adjusted along the length of the conveyor, allowing for discharge on one or both sides.

- Inlet Feeder: Can be integrated to run on the conveyor belt for flexible grain input.

- Cover and Dust Guard: Optional cover and dust guard below the belt protect material and conveyor from weather and dust.

- Speed Sensor: Monitors and controls belt speed, issuing an alarm for service attention before a shutdown occurs.

- Multiple Intakes: Supports several intake points installed on a single conveyor belt.

- Belt Scraper: Effectively cleans the belt during operation, keeping the return side clean and preventing spillage.

Downloads

Download brochures, manuals, and spare parts lists for the BCB belt conveyors.

Brochures

Manual and Spare Parts

BCB Belt Conveyor Applications

The BCB Series grain belt conveyors are perfect for a range of grain handling applications, whether for horizontal or inclined conveying. Their adaptability makes them ideal for use in grain storage facilities, seed processing plants, and general agricultural operations where cleanliness, efficiency, and flexibility in grain handling are required. The self-cleaning design and modular system ensure minimal maintenance and maximum productivity.