Pre-cleaning grain by weight and size

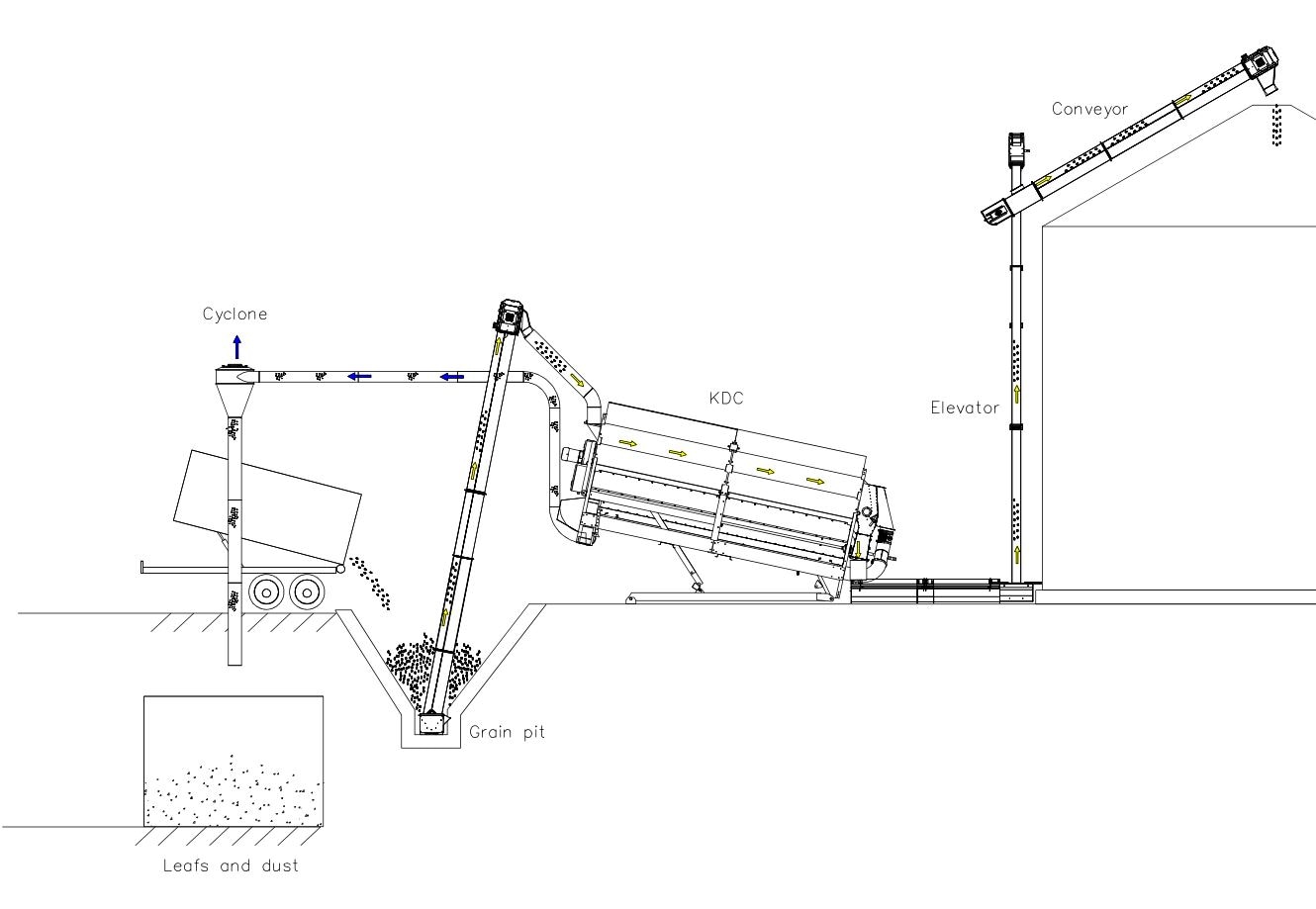

In order to remove heavier impurities from the grain, it is necessary to use a cleaning process, also called pre-cleaning. The first screen section separates large impurities (oversize) from the grain. The next screen section retains the good grains, while small grains and small impurities such as sand are separated.

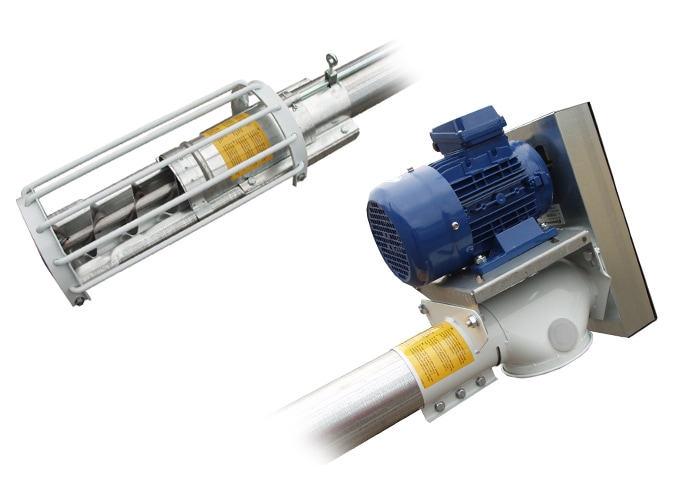

After processing on the screens, the grain passes through a suction and cleaning section, which removes the remaining dust and light particles in the good grain.

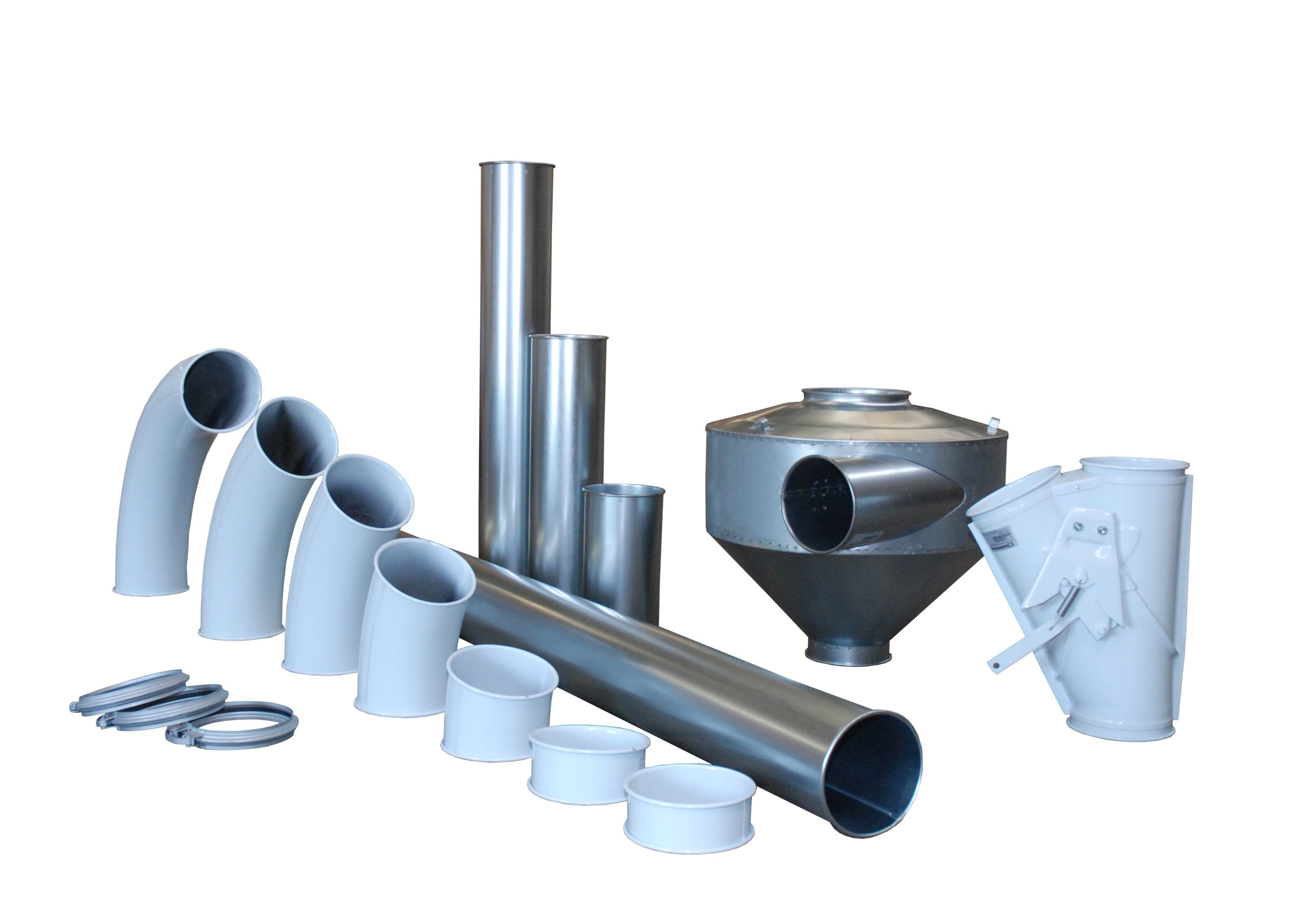

The impurities and screenings are transported through pipes to be discharged through a cyclone to a storage facility, such as a trailer.

Case Study

Cleaning of Pig Feed – Bøgekærgård

Bøgekærgård, a Danish pig farm, struggled with grain impurities affecting feed quality and equipment performance.

Videos of Related Systems and Products

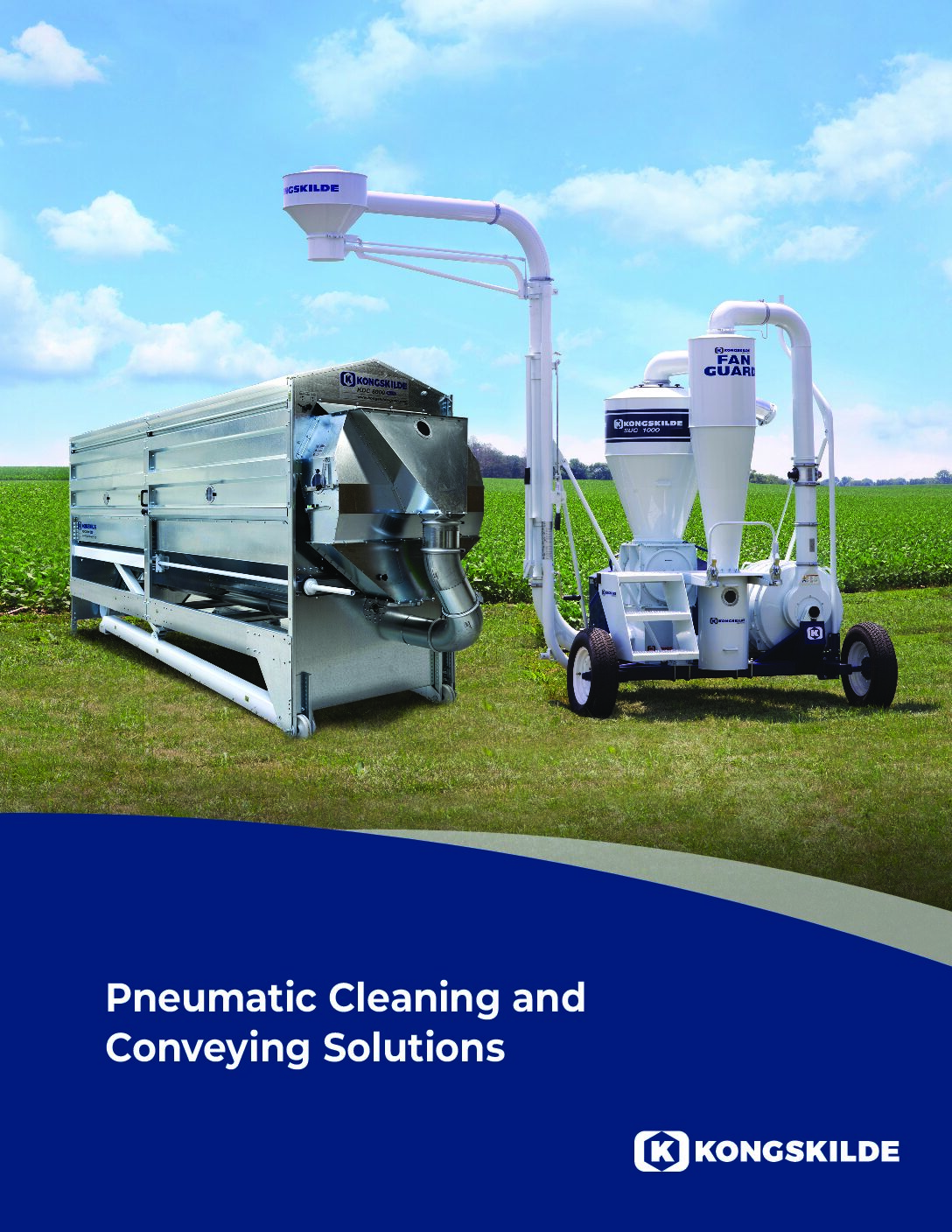

KDC PLUS is a combined cleaning system with a capacity of up to 80 tonnes per hour. Ideal for pre-cleaning maize, barley, wheat, rye, peas and beans, and for sorting malting barley and seeds.

Download Resources

Download the latest PDF documents, brochures, datasheets, manuals and more.