Weighers

Weighers – KA

Kongskilde’s twin-compartment batch weighers operate on a continuous batch weighing principle, in which the material flows constantly through the weigher at a given capacity.

Weighing is based on establishing a balance between the batch of the material and the weigher’s fixed weight. This ensures optimum accuracy, irrespective of the material being weighed.

The robust but simple construction of the weighers ensures their reliability and makes the various models well-suited to many agricultural and industrial applications.

KA Weighing System

The weighing system is based on a compartment containing a certain amount of grain which is filled up to be in balance with a counterweight. The weigher is equipped with two compartments working in sequence. During filling of the one compartment, the other one is emptied.

If there is a demand for taking out a certain amount of grain, it has to be integrated into the conveying system in such a way that it is possible to convey the grain through the weigher when emptying.

The weighers can be used for weighing of cereals with kernel sizes up to 15mm and coarse ground materials (not too fine), which are not bridging.

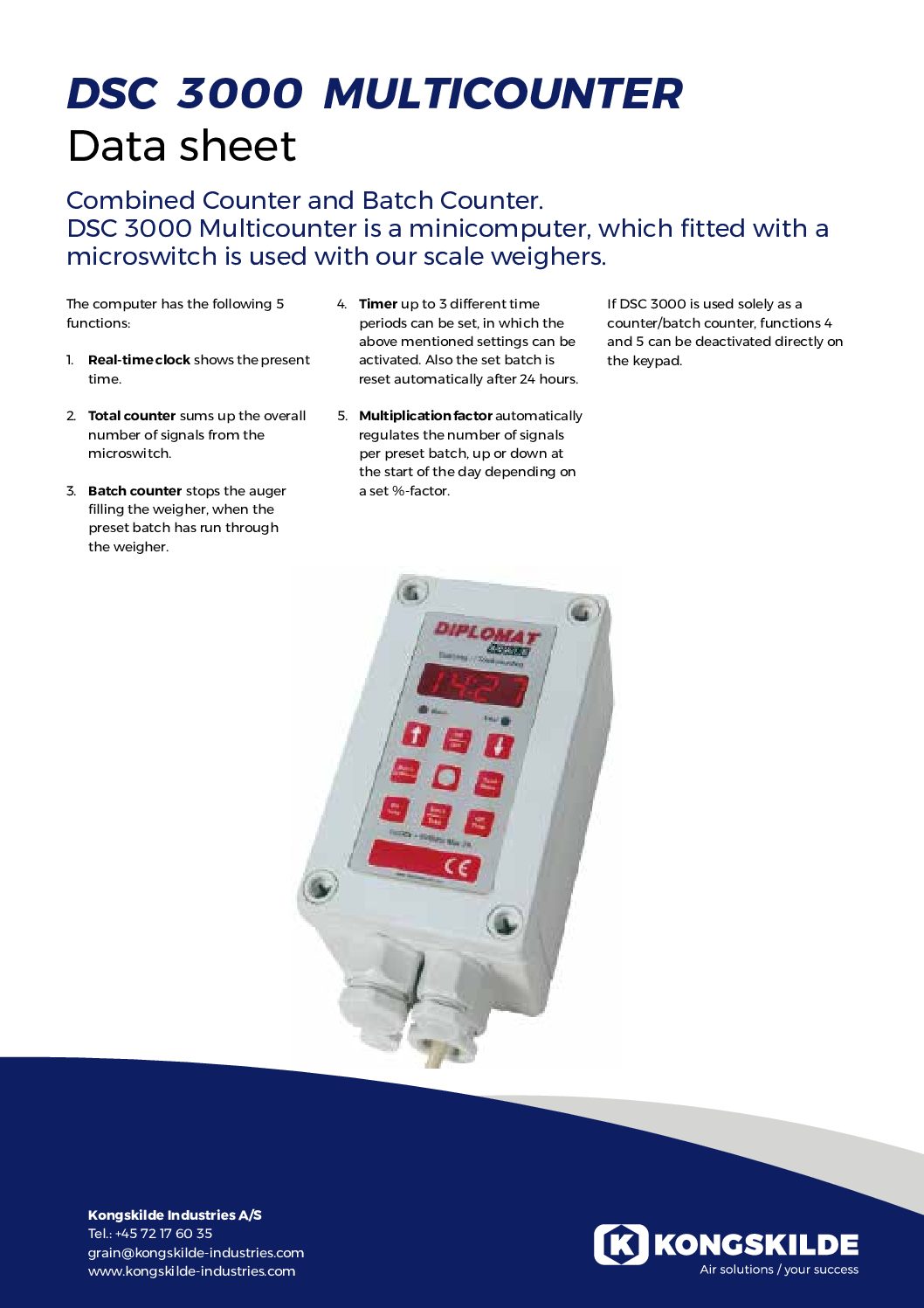

The weighers can be equipped with pre-programable counters to be used in systems for preparing feed stuff consisting of different ingredients which must be added according to recipe. The control system can either be based on a mechanical or electrical system. The system can be used for controlling the operation of connected conveying systems.

Highlights

- Suitable to be built into conveying systems for storage filling.

- Suitable for mixing and feeding installations.

- Intended for internal weighing (not calibratable).

- Robust and simple construction ensures reliable operation.

- Suited to many different applications, such as cereals and other granular materials.

Downloads

Download brochure, data sheet, manuals, and spare parts lists for the KA weighers.

KA Weigher Applications

The KA weigher is suitable for many different applications, such as cereals and other granular materials and can be built into conveying systems for storage filling or used in feed mill systems.