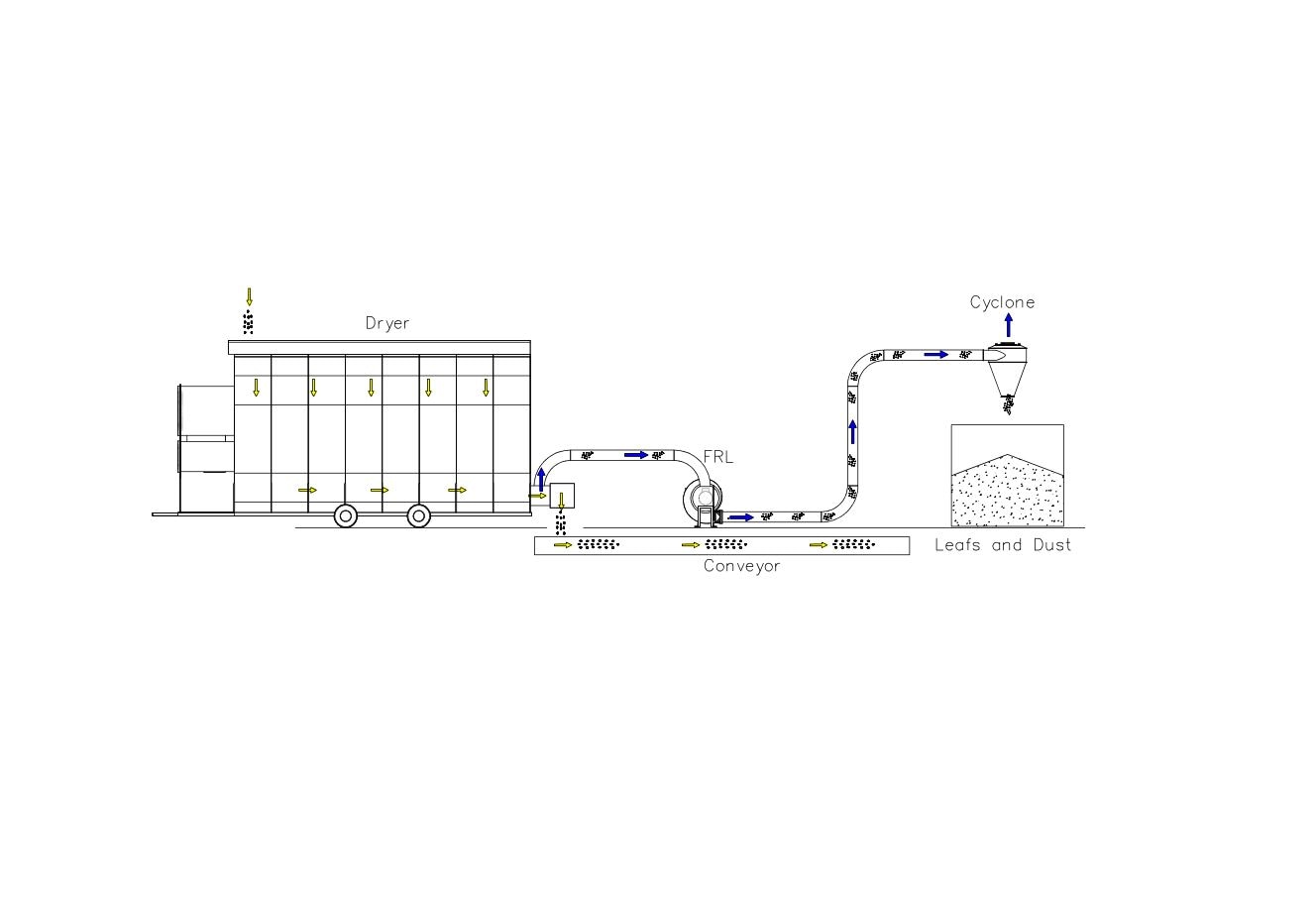

Pneumatic aspiration cleaning at the grain dryer discharge

On a wet crop, light material and dust tend to stick to the kernels. As an example, when handling corn, bees’ wings (leaves) tend to stick to the corn kernel when wet.

When the corn has passed through the drier, the small leaf is detached from the kernel. The leaves are thus easy to separate by use of vacuum from the corn at the discharge end of the drier, and then conveyed to be discharged somewhere else.

By minimizing the content of leaves and dust in the crop, the storage of the crop is made safer. A very limited concentration of leaves and impurities is present at the center of the silo under the filling point, which reduces the risk of unventilated areas at the center of the silo.

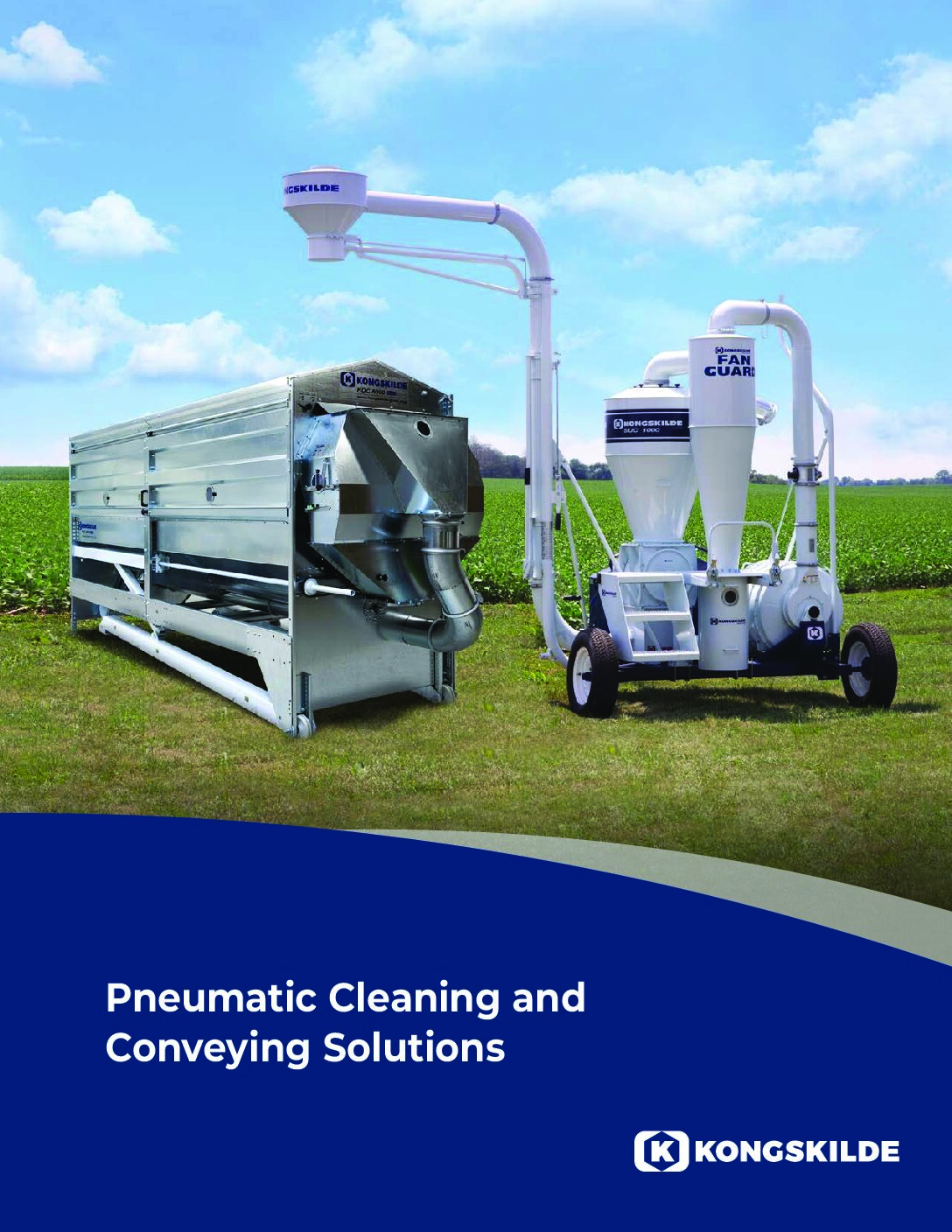

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.