Separation and Cleaning of Mixed Crops

With a total farm area of 488 hectares, Rolf Hach faced multiple challenges in post-harvest processing. His primary goal was to achieve a multi-stage cleaning process to ensure efficient grain storage, high-quality separation, and long-term sustainability.

- Mixed-Crop Separation: Oats and peas were cultivated together in the same field as a mixed crop, making it difficult to separate them during post-harvest handling. Proper separation was essential to ensure storage efficiency and maintain product quality.

- Grain Storability & Quality: The farm needed an advanced pre-cleaning and main-cleaning process to remove impurities, dust, and small debris, ensuring the grain was properly stored without spoilage risks.

- Seed Processing for On-Farm Use: A crucial part of the farm’s operation involved processing high-quality oat seeds for future planting. Any residual contaminants could impact seed viability and overall crop health.

- Oilseed Contamination: The oats contained undesirable oilseeds, which reduced their market value and usability. Without a proper system in place, removing these small foreign particles was a time-consuming and inefficient process.

- Sustainable & Efficient Processing: As an organic farm, maintaining sustainable grain handling practices was a priority. The cleaning process needed to be efficient, eco-friendly, and adaptable to different grain types.

The Solution

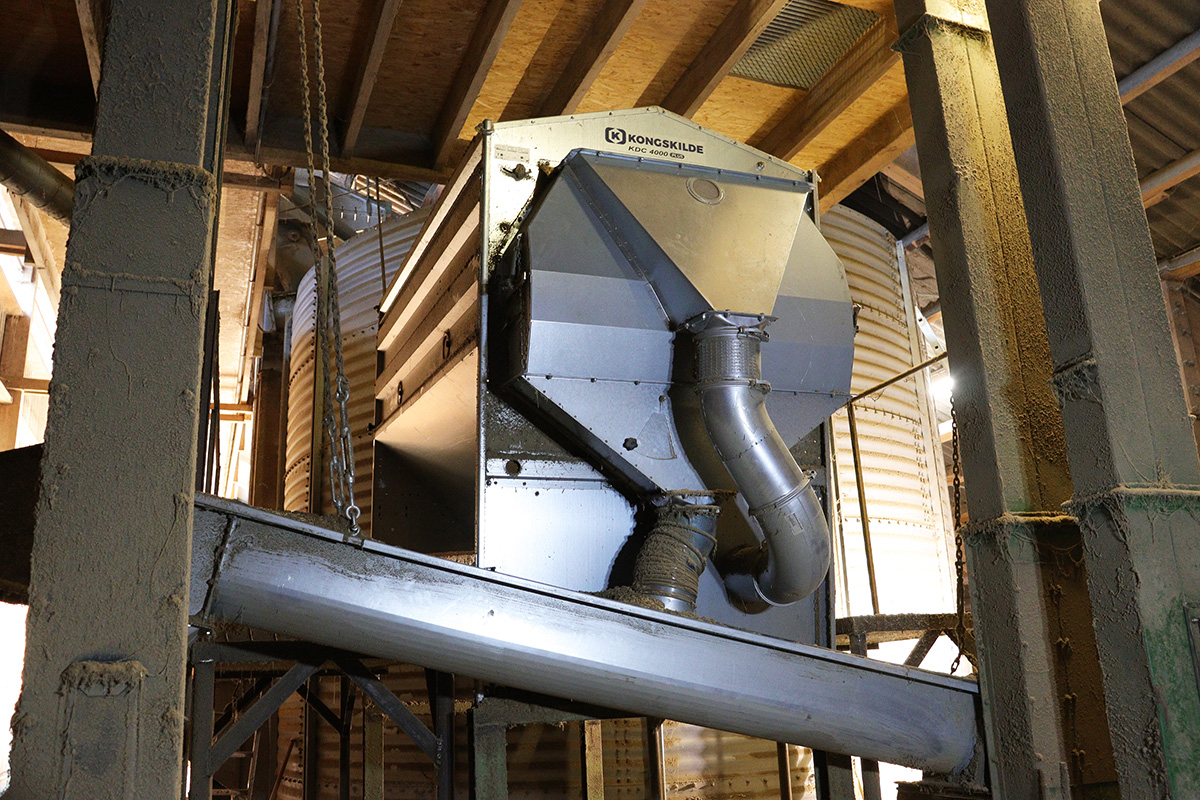

To address these challenges, Rolf Hach implemented the KDC 4000 PLUS, a high-performance grain cleaner designed for efficient multi-stage processing:

- Pre-Cleaning – The KDC 4000 PLUS efficiently removed field debris, dust, and lightweight impurities, ensuring a cleaner starting point for further processing.

- Main Cleaning – By using optimized airflow technology, the system effectively separated oats and peas, allowing for proper storage and maintaining grain integrity.

- Seed Cleaning – The precision of the KDC enabled the farm to produce high-quality oat seed for future cultivation, improving sustainability and seed viability.

- Oilseed Removal – With its specialized sieves and airflow adjustments, the system successfully extracted undesirable oilseeds from the oats, restoring grain purity and increasing market value.

- Seamless Integration – The KDC was installed while utilizing the farm’s existing conveying equipment, minimizing the need for additional infrastructure and ensuring a smooth transition.

With its compact design and advanced separation technology, the KDC 4000 provided a fast, efficient, and reliable solution, improving grain handling while simplifying farm operations.

The Results

The impact of the new cleaning system was immediate and highly effective:

- Successful Separation of Oats and Peas – The system efficiently processed the mixed crop, achieving the desired separation.

- Improved Grain Quality & Storability – Cleaner grain resulted in better storage conditions and reduced spoilage risks.

- Higher Operational Efficiency – The farm streamlined its workflow, reducing manual labor and optimizing grain handling.

- Effective Oilseed Removal – The system successfully removed unwanted oilseeds from the oats, improving overall grain purity.

- Immediate Results – The improvements were visible from the very first use, confirming the system’s effectiveness.

“We have benefitted from the increased efficiency, quality, and capacity of the cleaner. Any problems we previously encountered while cleaning our grain were quickly solved by the KDC.“

Lars & Rolf Hach

Rolf Hach Landwirtschaftlicher Betrieb

Ready to transform your grain cleaning?

Get in touch to start the conversation and discover how our cleaning solutions can improve your operations.