Efficient Pre-Cleaning of Grains by Weight and Size

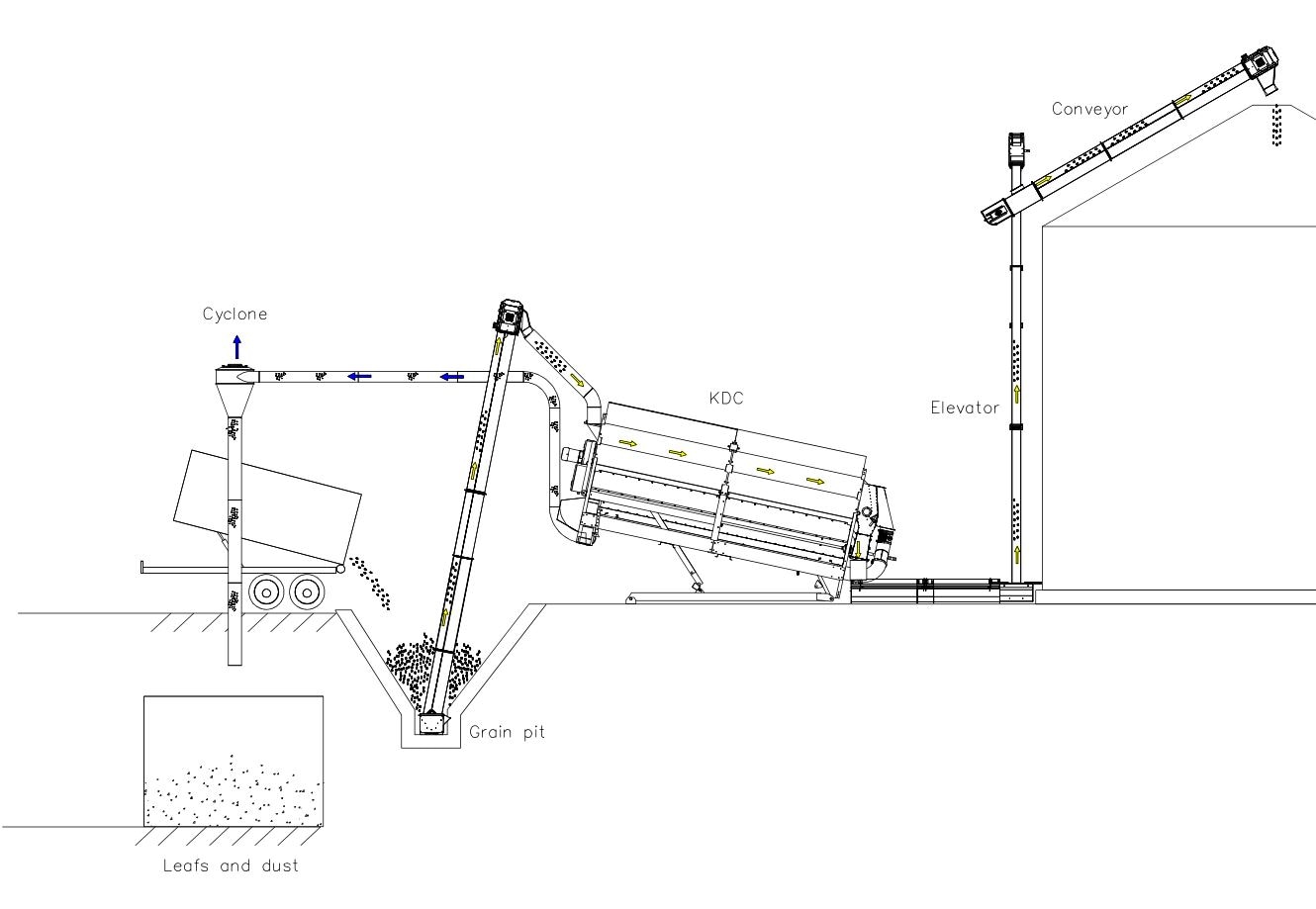

Effective grain pretreatment begins with separating impurities by both size and weight. Kongskilde’s grain cleaner systems perform an initial screening that removes large contaminants such as straw, clumps, and oversized material. The following screen section retains good grain while filtering out smaller particles like sand and underdeveloped kernels.

Once separated mechanically, the cleaning of grains continues in a suction section, where dust and lightweight debris are extracted to ensure a high-quality result. This final step ensures a batch of clean grain that’s optimized for storage, sale, or further processing.

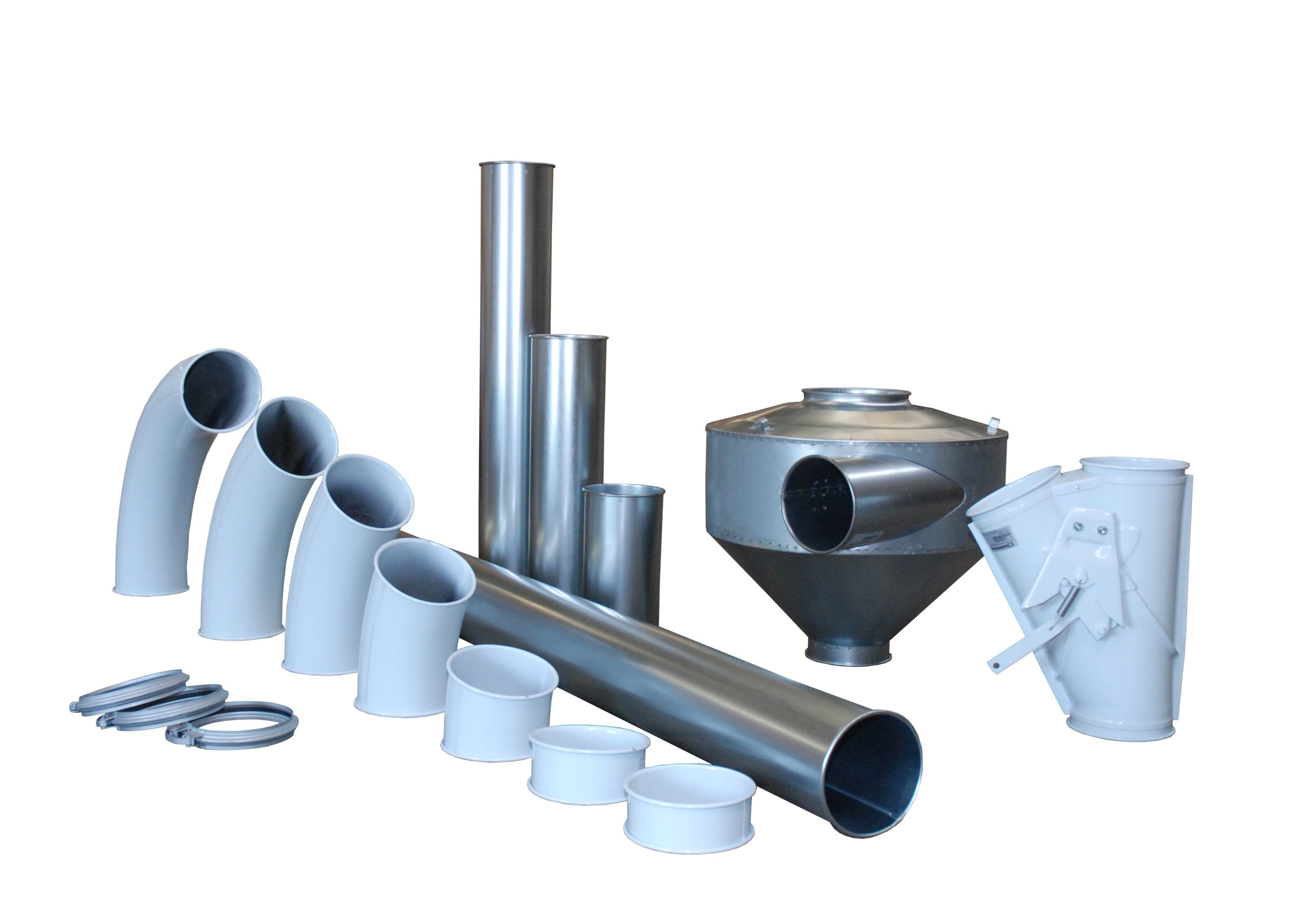

All screenings and waste materials are pneumatically conveyed through pipes and discharged via a cyclone into a designated container, such as a trailer, for easy handling and disposal.

Case Study

Cleaning of Pig Feed – Bøgekærgård

Bøgekærgård, a Danish pig farm, struggled with grain impurities affecting feed quality and equipment performance.

Videos of Related Systems and Products

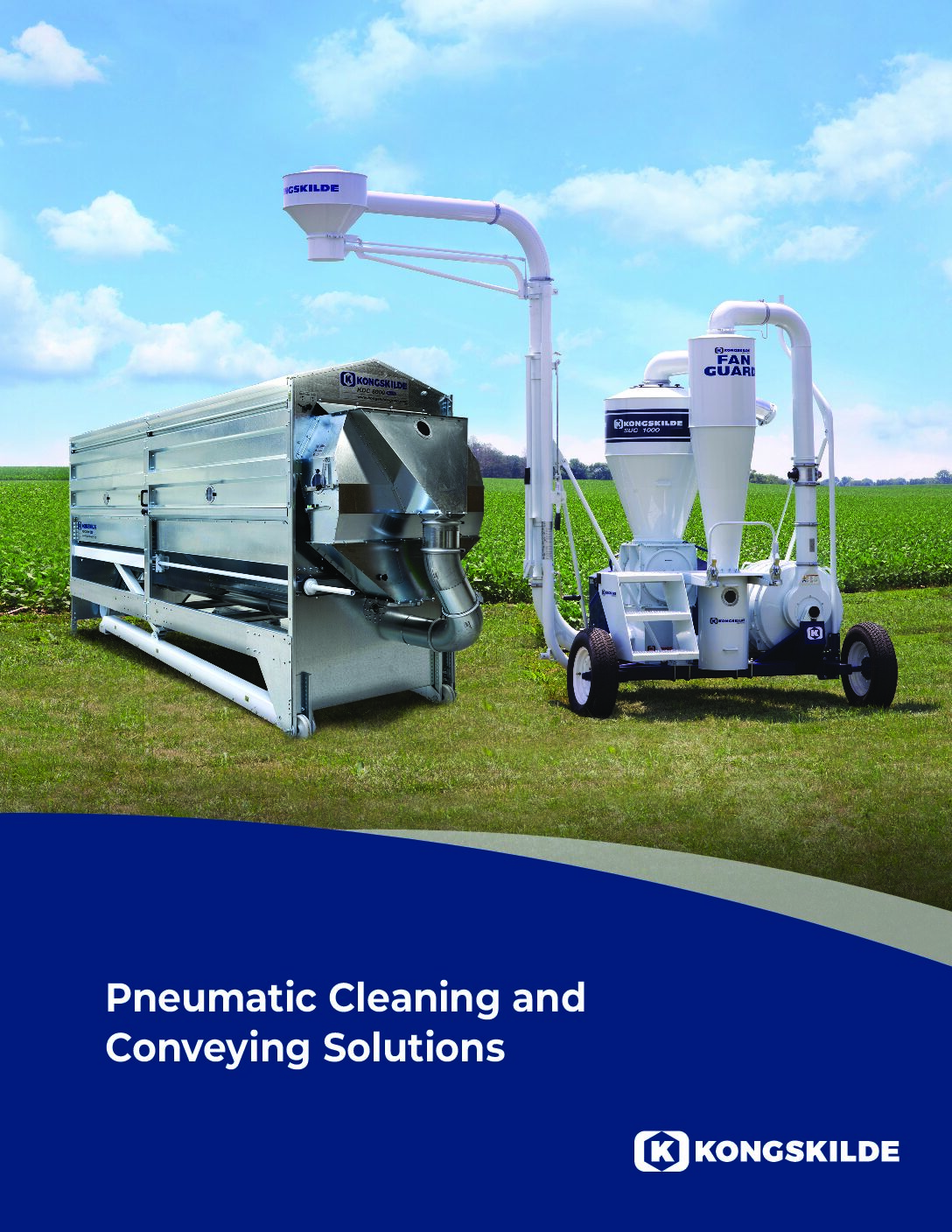

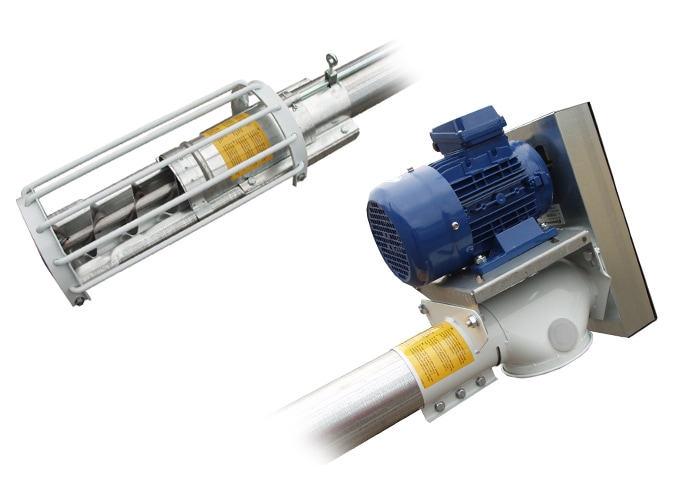

Kongskilde’s KDC PLUS is a high-capacity grain cleaner combining screen and aspiration cleaning in one system—perfect for grain pretreatment of maize, wheat, barley, rye, peas, beans, and seed crops. With up to 80 t/h throughput, it’s ideal for operations prioritizing clean, sorted grain.

Download Resources

Download the latest PDF documents, brochures, datasheets, manuals and more.