Pneumatic Conveyors

High-Pressure Blowers – TRL

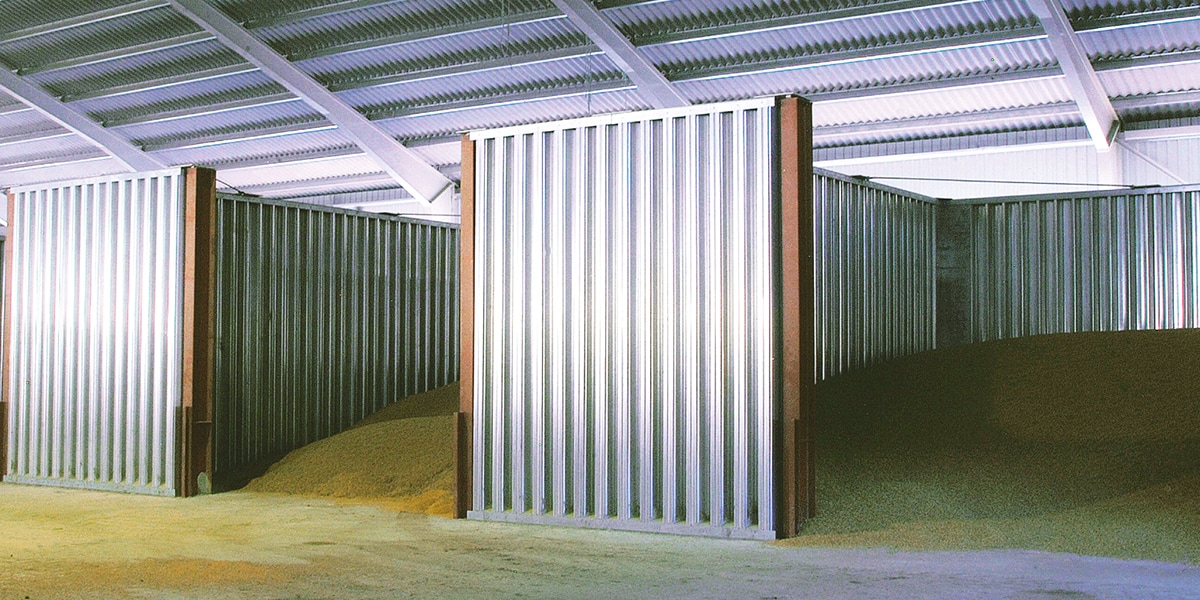

Kongskilde’s TRL high-pressure blowers are designed for efficient conveying in pressure conveying systems. These systems are ideal for moving wheat, barley, oats, rye, corn, canola, soybeans, sunflower, and other granular products. With a variety of high-pressure blower models available, Kongskilde ensures the perfect match for your grain handling needs, offering flexibility in conveying capacities and system requirements.

In addition to serving as a powerful and efficient air source for conveying systems, TRL blowers are also ideal for a wide range of other applications that require high-pressure airflow.

Pressure conveying systems are highly effective at conveying grain over long distances, whether horizontally, vertically, or around obstacles. Grain is fed directly into a hopper above the injector or rotary valve, where the blower creates a powerful airflow to carry the product gently through the smooth conveying pipes. This flexible system helps move grain efficiently to multiple delivery points.

How a High-Pressure Blower System Works

In a pressure conveying system, the blower’s pressure side connects to the conveying pipe, generating a powerful air stream that moves grain through the system. The injector or rotary valve feeds the grain into the piping, while diverters allow the grain to be delivered through pipes to various locations efficiently. This air-driven system ensures smooth and gentle conveying of grain without causing damage to the product.

Key Benefits of High-Pressure Blowers:

- Space-Saving Installation: The lightweight conveying pipes can be installed in almost any location, minimizing the need for large, heavy equipment.

- Flexible and Modular: With a wide range of modular pipe components joined quickly and securely with clamps, the system is adaptable to various configurations and building structures.

- Minimal Installation Requirements: Only electrical connections to the blower and rotary valve intake are needed, simplifying the setup process.

- Easy Capacity Regulation: The shutter on the rotary valve intake unit allows for easy control and adjustment of conveying capacity.

- Maximum Capacity: Achieve high performance and maximum capacity with pressure conveying systems by using an efficient air flow control system.

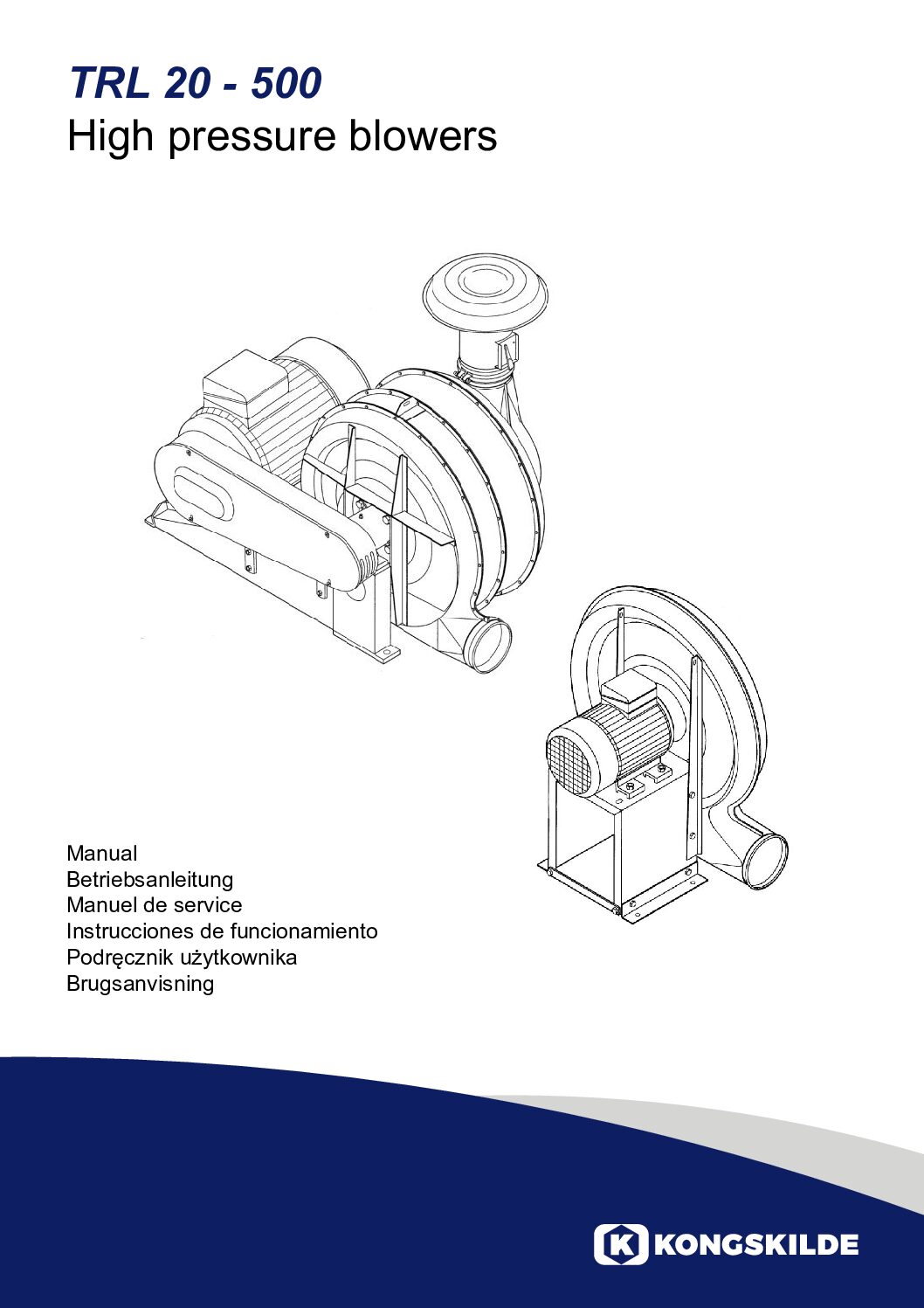

Small TRL Blowers – Direct Driven

In small TRL high-pressure blowers, the rotor is directly attached to the motor shaft, offering a compact and efficient solution for generating airflow in the conveying pipes. The direct drive system ensures reliable performance while reducing the maintenance requirements of the blower.

Key Features of Small TRL Blowers:

- Direct Drive Efficiency: The direct connection between the motor and rotor maximizes power transfer and airflow efficiency.

- Balanced Rotors: Dynamically balanced rotors provide smooth and quiet operation, minimizing system wear and noise.

- Airflow Control: Efficient airflow control reduces pipe wear and prevents grain damage during conveying.

- Low Maintenance: Designed for minimal upkeep, the direct-driven TRL blowers offer long-lasting reliability.

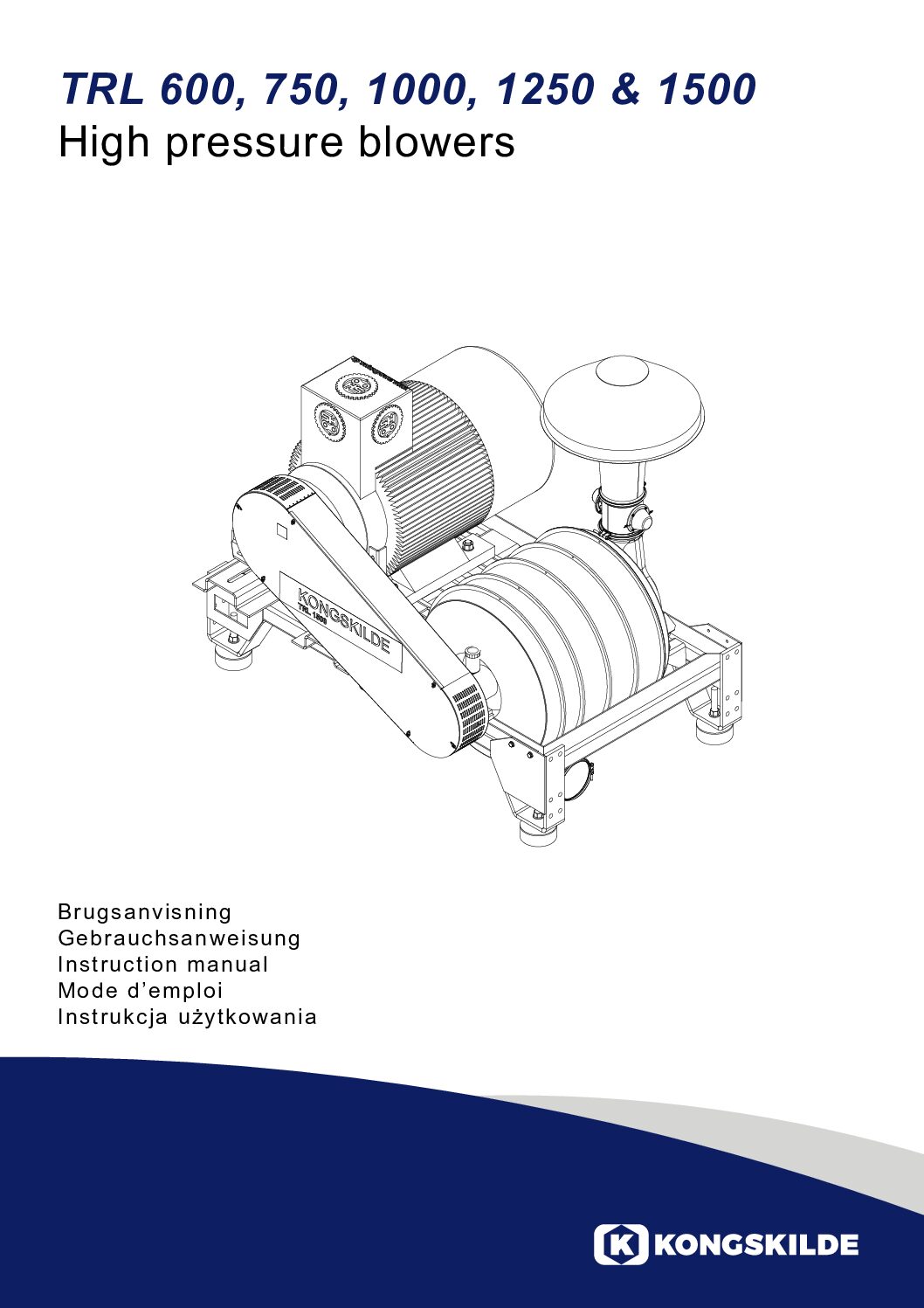

Large TRL Blowers – Belt Driven

For larger capacities, belt-driven TRL blowers use a belt drive to connect the motor shaft to the blower shaft. This system allows for multiple rotors, increasing pressure and capacity for handling higher volumes of grain.

Key Features of Large TRL Blowers:

- Modular Design: The belt-driven system allows for customization of blower capacity based on your specific needs.

- Proven Reliability: Extensively tested and designed for long-term performance.

- Airflow Consistency: Air flow control ensures a constant and gentle airflow, protecting grain quality during conveyance.

- Versatile Use: Suitable for both pressure and suction systems, providing flexibility in grain handling operations.

Blowers with Electronic Air Regulator (EAR)

Only available in North America

The Electronic Air Regulator (EAR), provides precise and adjustable airflow control to protect grain during conveying. This innovative solution reduces the risk of damage while filling bins, silos, or flat storage. The EAR system ensures that whether fragile grain is conveyed horizontally, vertically, or around corners, it remains safe and undamaged throughout the process.

Downloads

Download brochures, manuals, and spare parts lists for the TRL high-pressure blowers.

Brochures

Manuals

Spare Parts

TRL Model Comparison

Compare available TRL blower models. Visit the downloads section for more information on specific models.

| TRL 20 | TRL 40 | TRL 55 | TRL 75 | TRL 100 | TRL 150 | |

|---|---|---|---|---|---|---|

| Blower rpm | 3000 | 3000 | 3000 | 3000 | 3650 | 4200 |

| Amp. consumption | 3.1 | 4.4 | 7.5 | 10.5 | 20 | 27 |

| Motor rating, kW (HP) | 1.5 (2) | 3 (4) | 4 (5.5) | 5.5 (7.5) | 7.5 (10) | 11 (15) |

| TRL 200 | TRL 300 | TRL 500 | TRL 600 | TRL 750 | TRL 1000 | |

|---|---|---|---|---|---|---|

| Blower rpm | 4700 | 4100 | 4300 | 3905 | 4310 | 4780 |

| Amp. consumption | 33 | 39 | 65 | 78 | 96 | 129 |

| Motor rating, kW (HP) | 15 (20) | 22 (30) | 37 (50) | 45 (60) | 55 (75) | 75 (100) |

Videos

TRL High-Pressure Blower Applications

Kongskilde’s TRL high-pressure blowers are ideal for use in pressure conveying systems, providing efficient and gentle transportation of grain. These blowers can move grain from one location to another, whether over long distances, vertically into storage, or horizontally through a facility. Their flexibility, durability, and capacity make them the perfect solution for agricultural and industrial grain handling needs.