Grain Grading for Malting Barley

Achieve consistent barley grades and improve crop value with precision grain grading systems tailored for malting and seeding applications.

Efficient Barley Grading for Malting and Seed Use

When it comes to producing high-quality malt, barley grading plays a critical role. Grain used for malting must meet strict size specifications—typically requiring kernels above a certain thickness. Accurate grain grading ensures that only the most suitable kernels are used for malting, enhancing product consistency and quality.

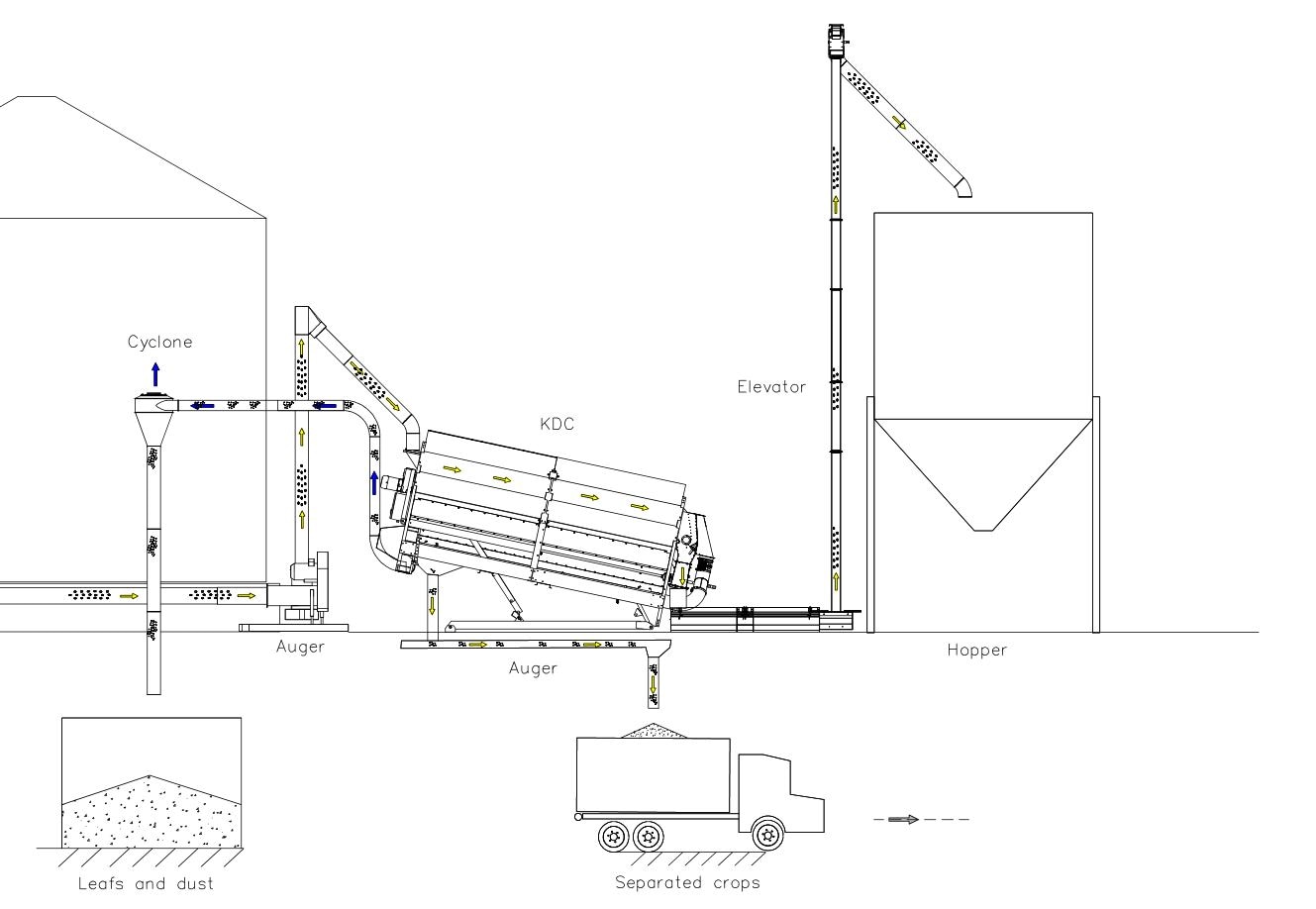

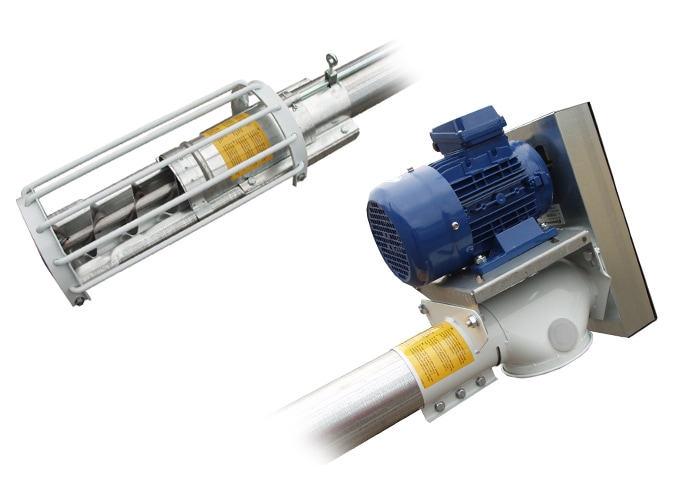

Kongskilde’s KDC dual cleaner is an ideal solution for separating barley and other grains into size-based fractions. This process not only helps meet malting standards but also reduces transportation and post-processing costs by delivering a ready-to-use product directly from the farm.

Grading is equally important for seeding. By separating out smaller kernels at the farm level, growers can ensure only top-quality seed is used while repurposing undersized grain for feed or fuel, improving both efficiency and sustainability.

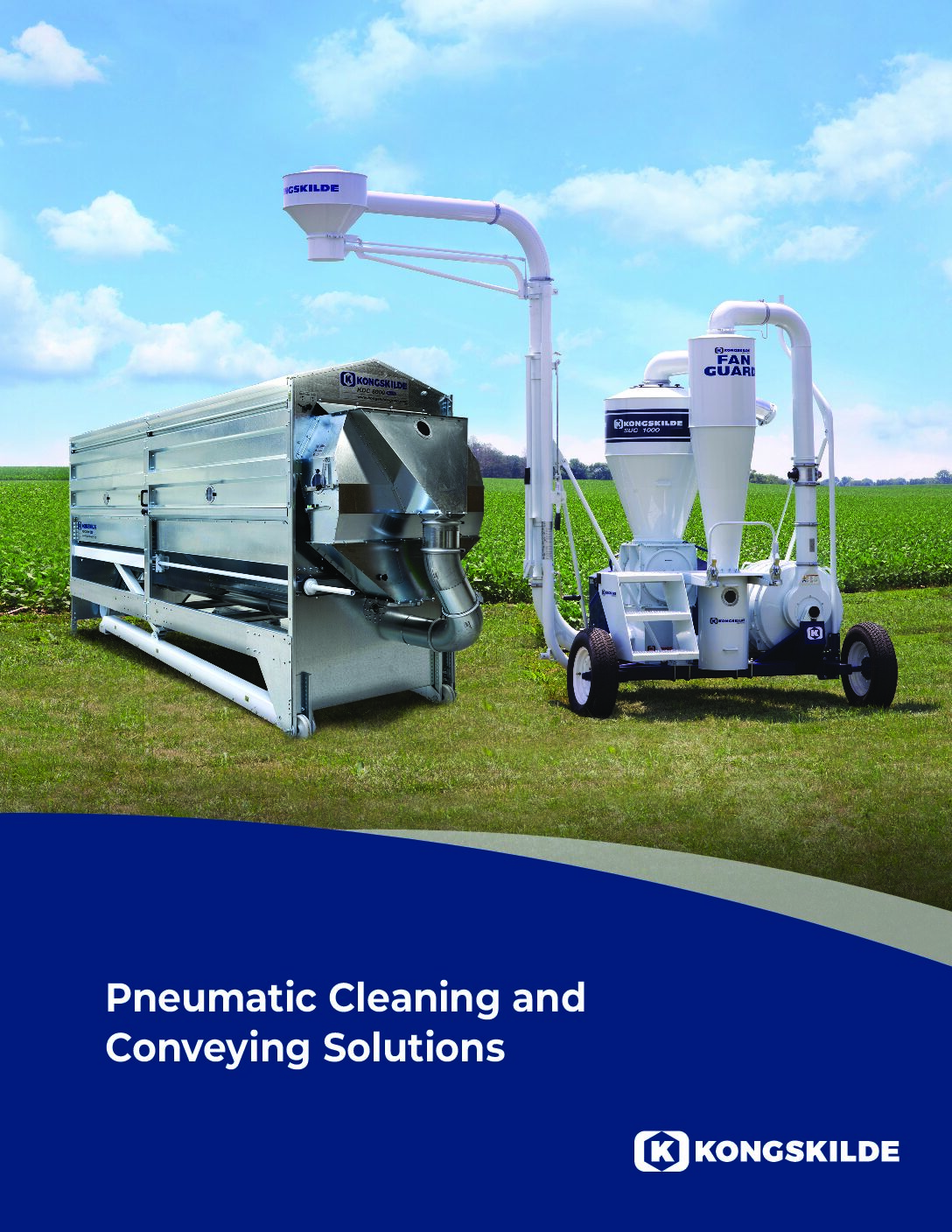

Grading Systems and Products

The Kongskilde KDC cleaner combines screen and aspiration cleaning in a single unit with a capacity of up to 80 t/h. It’s ideal for barley grading, as well as pre-cleaning and grain grading of crops like maize, wheat, rye, peas, and beans. The KDC is engineered for both malting and seeding operations.

Businesses We Serve

Whether you’re operating a conventional or organic farm, Kongskilde delivers precise and scalable grain grading systems to meet your barley grading specifications and streamline your grain processing workflow.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Related Products

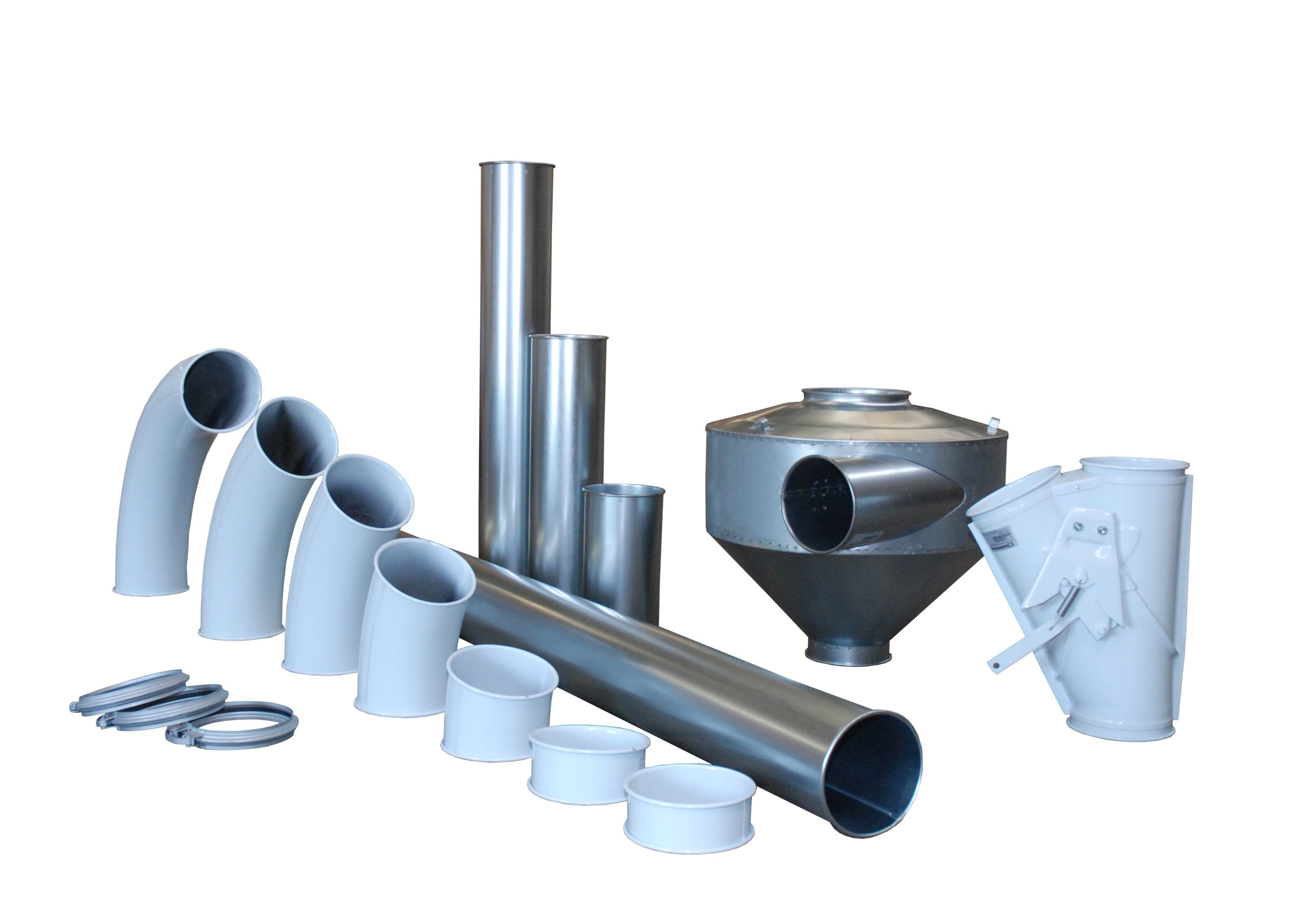

Designed for maximum flexibility, reliability, and quality, Kongskilde’s portfolio of complementary products offers additional customization for our world-class pneumatic systems.