Pneumatic Grain Conveying Systems for Dryers and Screening

Reliable, high-efficiency grain pneumatic conveying systems for moving grain to and from dryers, storage silos, and screening equipment.

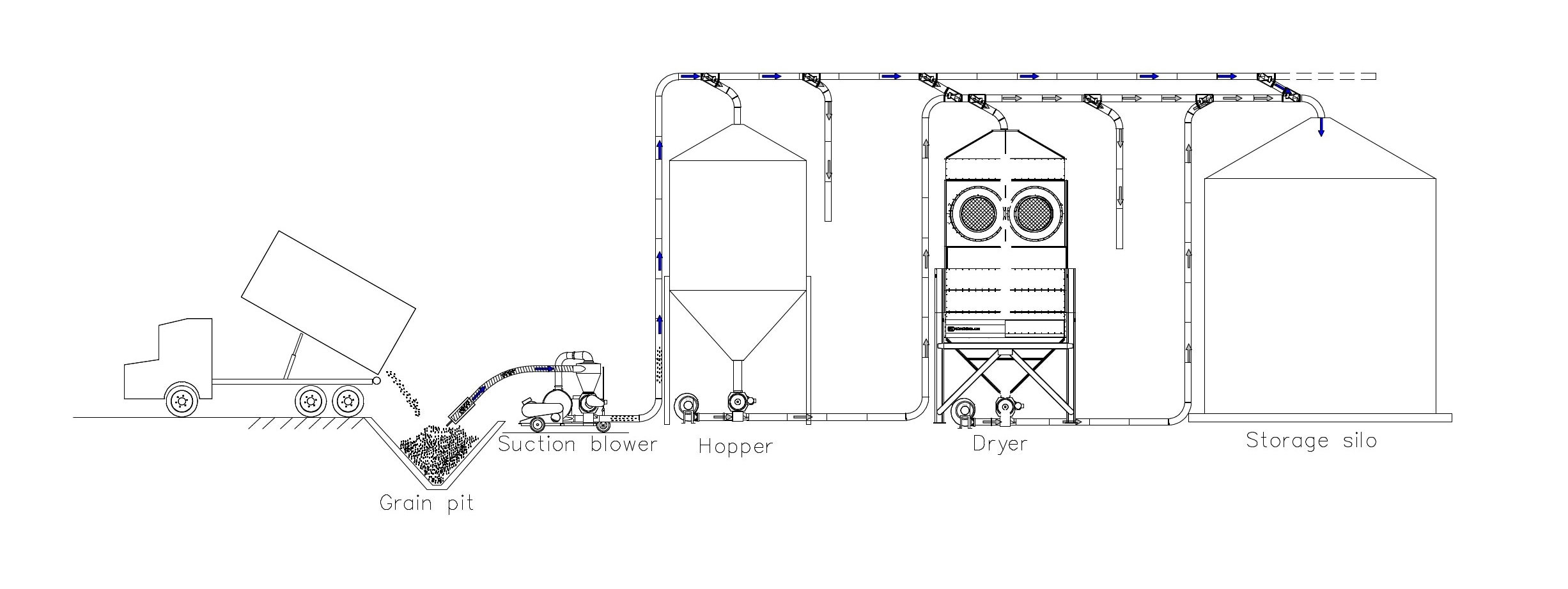

Integrated Conveying System for Grain Dryers and Screening Operations

Kongskilde offers versatile grain pneumatic conveying systems for transporting grain from the intake pit to wet holding bins, dryers, or storage silos—and between each step in the process. These systems can also be integrated with industrial grain screening machines to support fine separations industrial screening before or after drying.

Designed for continuous flow operations, this flexible setup allows the grain dryer to run at full capacity, independently of the intake and transfer process. During wet harvest seasons, where drying bottlenecks often limit throughput, this configuration helps maximize efficiency.

For batch or recirculating dryer systems, the conveying layout can be simplified to use fewer components, while still ensuring smooth and reliable material movement. One or two blowers may be operated depending on your specific drying and handling demands.

The pneumatic conveying system is 100% self-cleaning. No grain will remain in the pipe system or anywhere else when the conveying is finished.

Portable Pneumatic Conveying in Action

Kongskilde’s SUC-E is a compact, mobile grain pneumatic conveying system ideal for indoor or outdoor use. Equipped with wheels, the SUC-E can be easily relocated for a variety of conveying tasks—from supporting drying operations to offloading screened material from industrial grain screening equipment

Businesses We Serve

Whether you manage an organic or conventional operation, Kongskilde delivers complete solutions for grain drying, fine separations industrial screening, and pneumatic conveying tailored to your process.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Related Products

Designed for maximum flexibility, reliability, and quality, Kongskilde’s portfolio of complementary products offers additional customization for our world-class pneumatic systems.