Ensuring Grain Silo Hygiene and Preparation for the Upcoming Harvest

The new harvest is imminent, making it essential to prepare grain storage facilities.

The following steps are recommended:

- Clean the Storage and System – Thoroughly clean storage areas and systems to prevent contamination from residual grain.

- Improve Crop Cleaning – Enhance the cleaning process of your crop.

Clean Grain and the Health of Livestock

Due to grain damage and higher concentrations of undesirable impurities, sows may consume less feed, leading to an increased incidence of diarrhea in piglets. Additionally, intestinal inflammations and bloating may become more common in sows and slaughter pigs.

As grain levels deplete, impurities and negative microflora concentrations rise. Mycotoxins, which can cause fertility issues and abortions in sows, pose a significant threat.

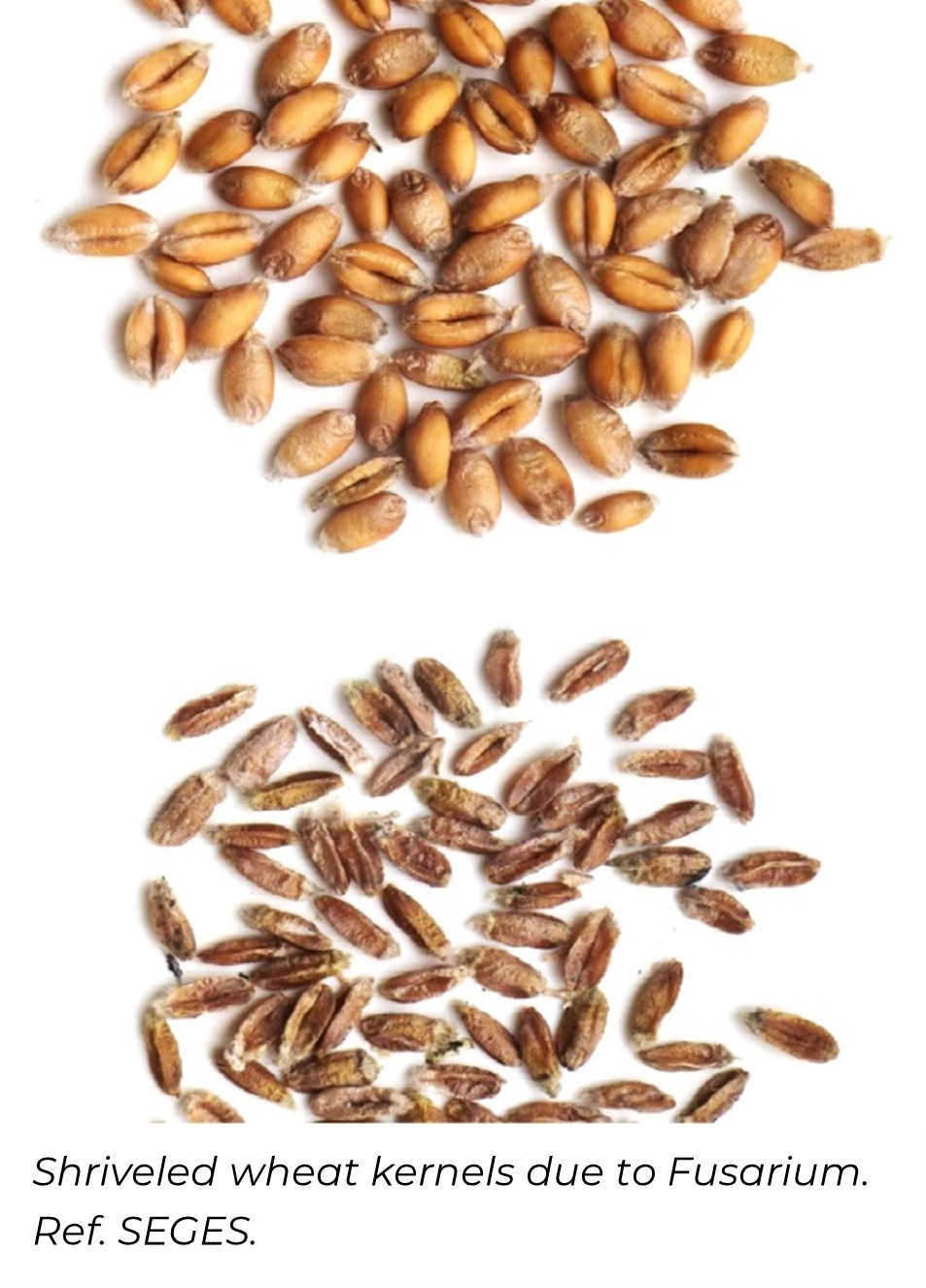

Traditionally, expensive toxin binders are used in feeding programs for sows and piglets until the new harvest. However, mechanical scalping and sorting, which remove fungus-damaged grain, offer a healthier alternative. This method also eliminates impurities and small kernels rich in negative microflora, reducing the need for synthetic vitamins.

Contamination in Storage

Additionally, it is necessary to inspect underneath the floor of steel silos/bins, where material may have accumulated over the season, potentially contaminating new grain. Suction blower systems effectively vacuum grain and dirt from floor openings, preventing material from being pushed below the floor.

For emptying and cleaning the lower levels of grain, a high-pressure suction blower coupled with a dual drum cleaner is an effective solution. This combination removes damaged grain fractions and impurities, ensuring high grain hygiene and healthy feeding programs. While these devices can be used separately, they are highly beneficial when used together.

By following these steps, farmers can ensure the cleanliness and hygiene of their grain storage, leading to healthier livestock and more efficient feeding programs.

Learn more about our grain cleaning and separation solutions

Featured Products

Questions?

Get in touch with our world-class customer support and technical specialists.