Hopper Filling and Emptying Systems

Reliable, high-performance conveying systems designed for efficient hopper filling and automated emptying of silos in grain handling operations.

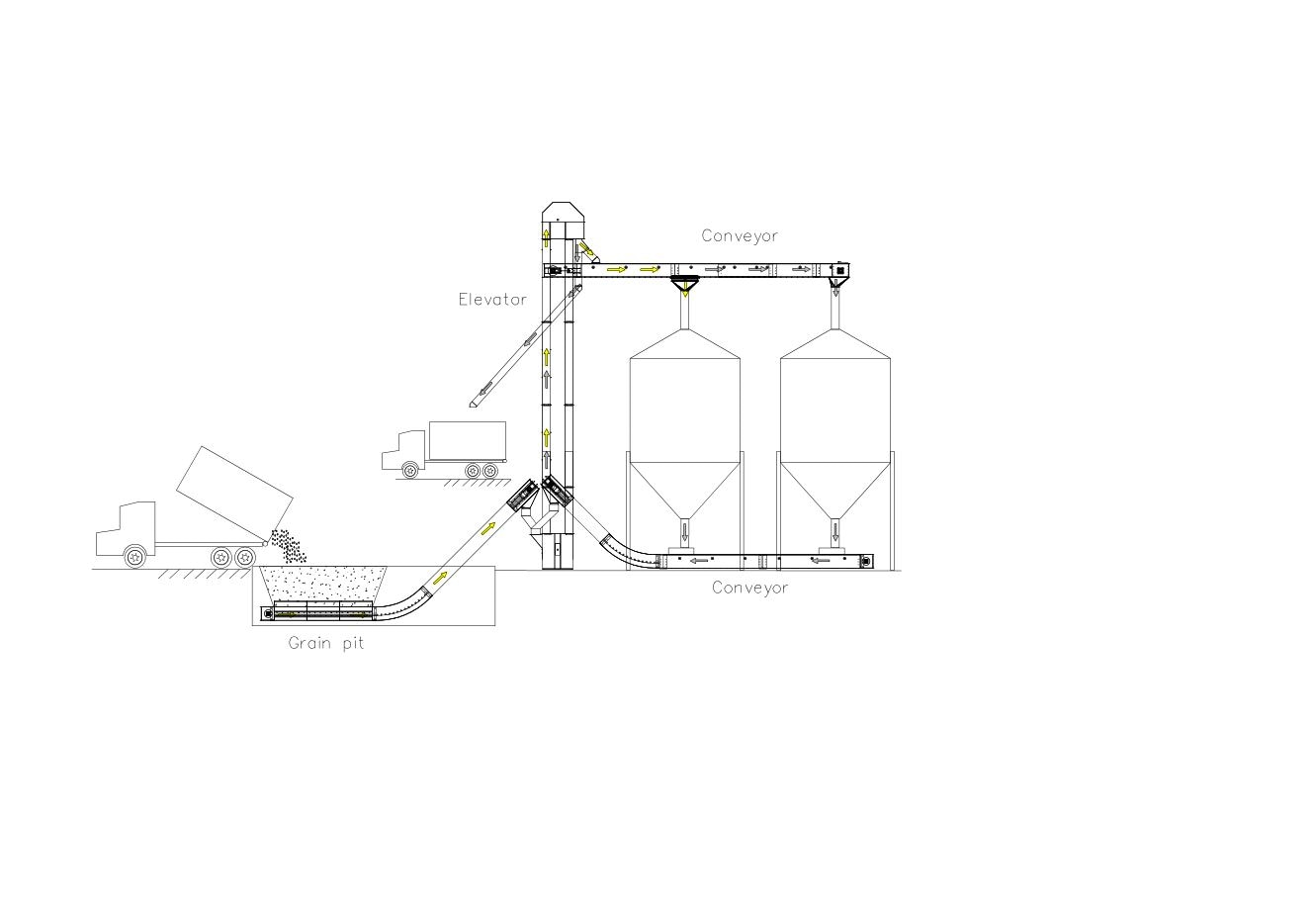

High-Capacity Mechanical Filling and Emptying System for Hopper Silos

Kongskilde offers complete conveying system solutions for both filling and emptying of silos, tailored for bottom-discharge hopper silos. Our mechanical setup ensures high throughput and low maintenance for both small and large operations.

Grain is first transferred to a pit, which may be installed either at ground level or below ground. From there, an angle conveyor moves the grain to a bucket elevator, which lifts it to a chain conveyor mounted on top of the silo array. This setup enables precise hopper filling at the silo inlets along the top.

For emptying silos, an angle conveyor is placed beneath each hopper outlet to collect grain and feed it into a bucket elevator. The elevator then transfers the grain for truck loading or into a downstream emptying system for further processing or storage.

The system is scalable and can be easily extended to serve multiple silos, offering flexibility for expanding operations and multi-bin layouts.

Businesses We Serve

Whether you run a conventional or organic farm, Kongskilde’s hopper systems deliver efficient, durable solutions for reliable grain storage, hopper filling, and silo discharge.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

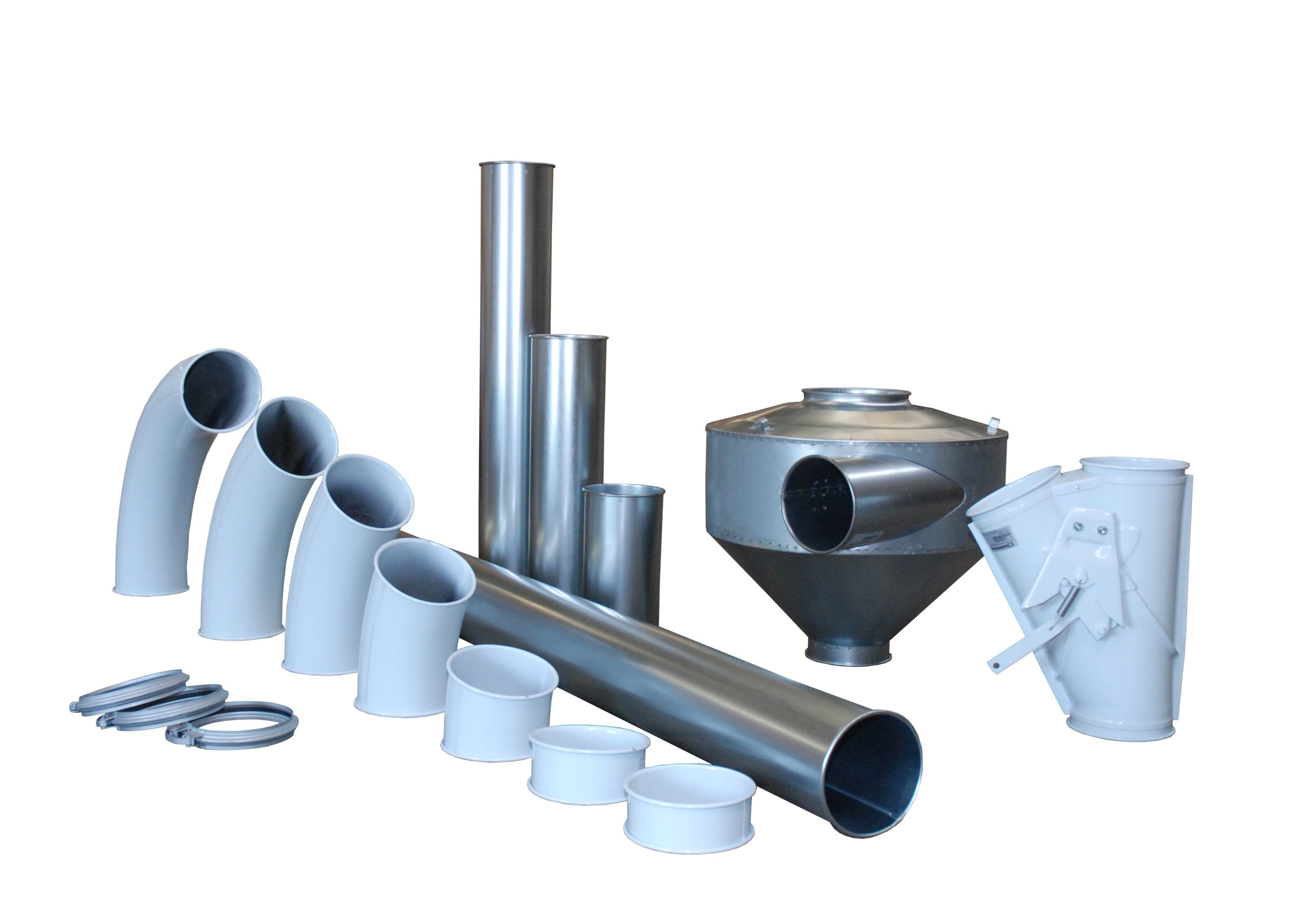

Related Products

Explore Kongskilde’s full range of pneumatic and mechanical components designed to integrate seamlessly with your hopper filling and emptying systems, ensuring maximum performance and customization.