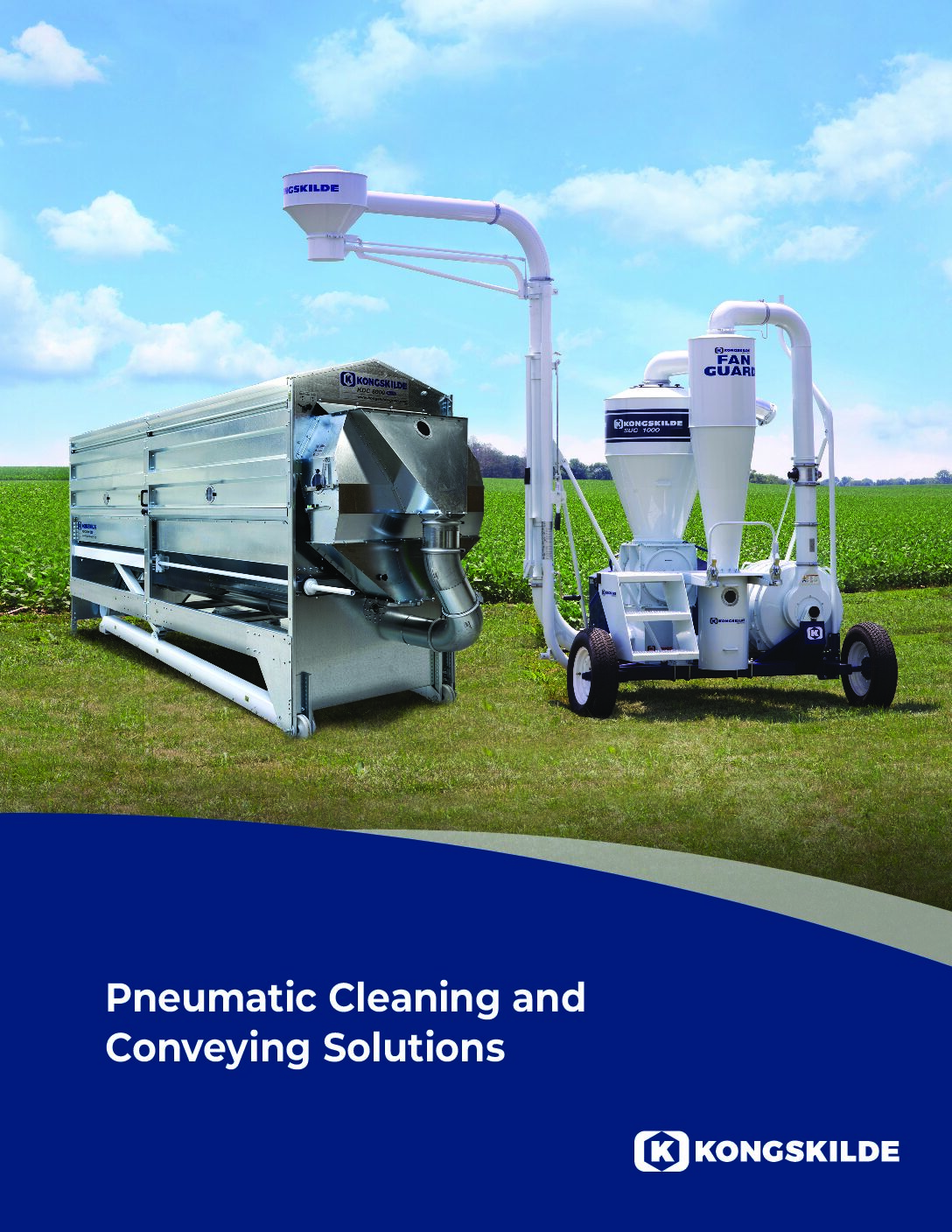

Pneumatic Conveyors

Material-Through Blowers – MTD

High-efficiency material-through blower

Kongskilde MTD blowers operate using a direct drive system, which means there is no loss of power through belts or gears. The centrifugal action of the backward-curved blades within the self-cleaning rotor efficiently propels materials through the system. This setup not only maximizes airflow but also ensures that any fine particulates are effectively removed during grain transfer or other material handling processes.

The range of MTD blowers covers air volumes from 750 m³/h to 11,000 m³/h— 7,000 CFM —and can achieve max pressures up to 440 mm (18” pt. inches) WG, with 60 Hz motor options available, accommodating a wide variety of operational demands

How Kongskilde MTD Blowers Work

Kongskilde MTD blowers operate using a direct drive system, which means there is no loss of power through belts or gears. The centrifugal action of the backward-curved blades within the self-cleaning rotor efficiently propels materials through the system. This setup not only maximizes airflow but also ensures that all fine particulates are effectively removed during aspiration cleaning or other material handling processes.

A volume of up to 7,000 CFM and a max pressure of 18” pt. inches WG can be reached.

Benefits of Kongskilde MTD and Material Handling Blowers

- Enhanced Efficiency: Designed to maximize airflow and pressure with a self-cleaning rotor that prevents clogging and maintains consistent operation.

- Durable Construction: Built with a 3mm steel plate housing, these blowers are robust enough for both indoor and outdoor use.

- Energy Efficient: Low power consumption due to the direct drive design, reducing operational costs.

- Versatile Applications: Ideal for pressure conveying systems to effectively convey fines, light trash, and other materials from one location to another.

MTD Blower Applications

Kongskilde MTD blowers are incredibly versatile, making them suitable for a broad spectrum of industrial applications. Their robust design and ability to handle large volumes of air make them ideal for:

- Fines Conveying: Perfect for transferring trash, fines, and chaff efficiently between processing units, or during the loading and unloading phases.

- Plastic Processing: Effectively used in the plastics industry to transport pellets, granules, and regrind materials from production lines to storage or processing machines.

- Waste Management: Ideal for moving industrial waste materials through recycling or disposal processes, where consistent and reliable handling is critical.

- General Industrial Applications: Suitable for any industrial setup requiring dependable air movement, including manufacturing facilities that deal with raw materials in bulk.

Downloads

Download brochures, manuals, and spare parts for the MTD series of blowers.

MTD Applications

The MTD blower series can be used in various pressure conveying systems to move grain from one place to another.