The French manufacturer of sorting and seed treatment plants, Ci2T, has experienced great success with integration of Kongskilde’s combi-cleaner, the KDC. Ci2T has a full range of mobile units, including many innovative options, to provide maximum cost-effectiveness and efficiency for the individual farmer.

Ci2T owner, Mr. Grégoire Dubois-Taine, explains why the KDC has been a leap forward for the Nancy-based company, “We constantly look to optimise the grain cleaning process. When we came across Kongskilde’s combined screen and aspiration unit, the KDC, we realised that is was a perfect fit with our mobile product line, the RX5.120, due to its compact and sturdy design combined with its large screen surface”. Mr. Dubois-Taine adds, “Obviously, the RX5.120 is exposed to all kinds of weather, so the fact that the KDC is made of galvanized steel is essential! Furthermore, all the wear parts are made of stainless steel, and we have experienced zero problems with the units”.

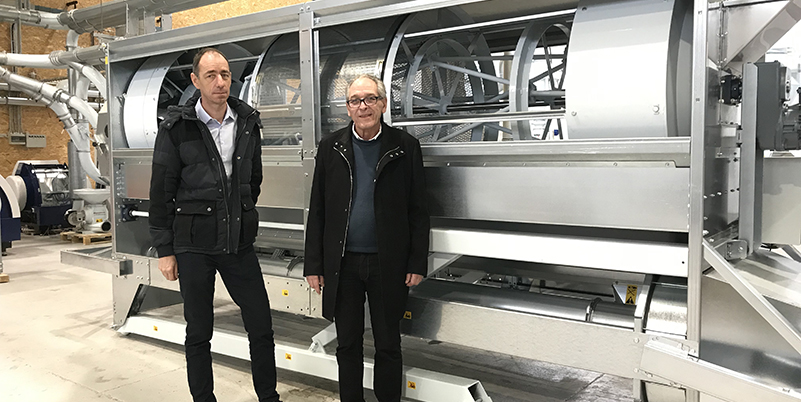

The RX5.120 combined with the Kongskilde combi-cleaner KDC

“This grain cleaning solution is ideal for both organic and non-organic cooperatives – and the RDX5.120 can be either rented or bought. We have sold several units outside France; in Italy and Rumania”, Mr Patrick Ervy, CEO of Air Vie, Kongskilde representative in France, concludes.

Mr. Grégoire Dubois-Taine (left) and Mr. Patrick Ervy in front of the KDC in the Kongskilde Technology Centre in Denmark.

The RX5.120 has a capacity of up to 80 t/h which makes it ideal for the pre-cleaning of maize, barley, wheat, rye, peas, and beans as well as for grading of malting barley and seed. Moreover, it can be operated by a single person by means of a smartphone application.