Kongskilde has delivered a pneumatic conveying system to RPC Packaging AS in Kristiansand, Norway for the conveying of plastic granulates.

RPC Packaging AS produces plastic trays for the food industry. They were in need of an effective and fast solution to convey their PE Pellets from the sack-emptying machine to two different silos – a distance of 100 m.

The Solution

The system consists of modular standard elements and ensures safe conveying of the pellets into the silos in the shortest possible time. No waiting time occurs!

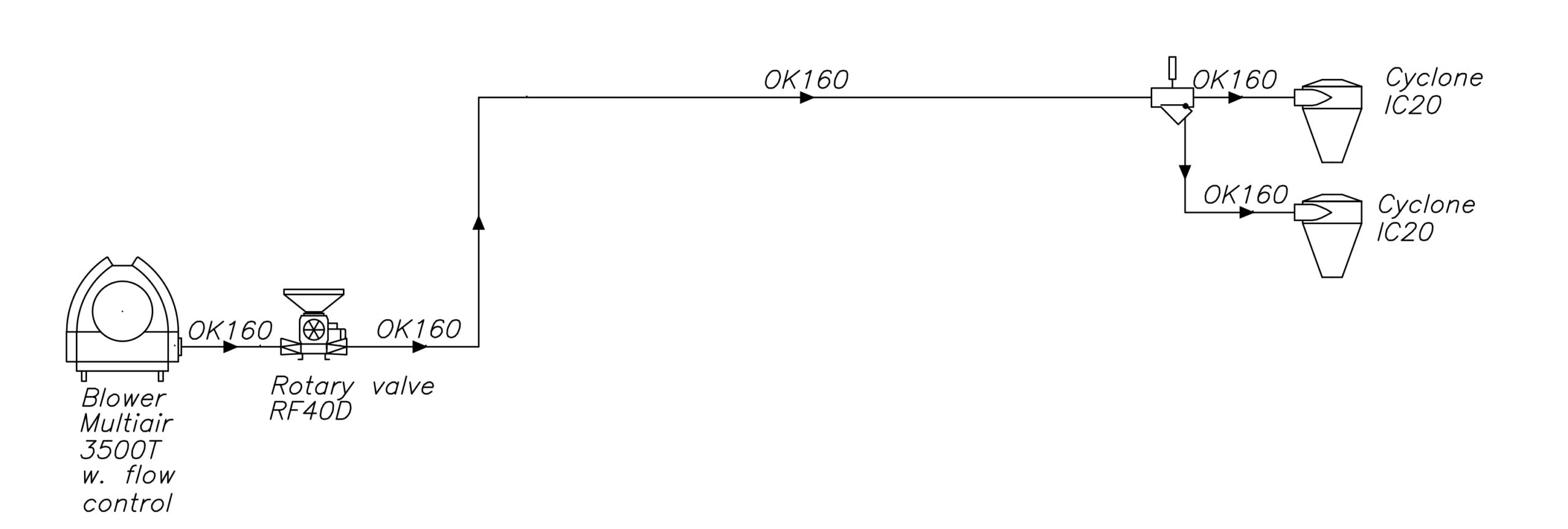

The solution consists of a MultiAir 3500 with frequency converter and a RF 40 Rotary valve.

It is designed to be cost effective with low operating and maintenance costs.

This solution is unique in terms of safe operation without any risk of contamination of the plastic pellets.

Top Three Benefits

1. High flexibility with a modular system for easy installation

2. Cost reduction by elimination of manpower for forklifts and trucks

3. Future-proof with easy addition of more silos

FACTS:

- Material PE Pellets

- Dimension of pellets max Ø3 mm

- Capacity needed 20 t/h

- Conveying distance vertical 10 mtr

- Conveying distance horizontal 100 mtr

- Bulk density 650 kg/m3

Svein H. Egestad, Managing Director of RPC Packaging AS, Kristiansand, Norway:

“The installation of a sack-emptying system together with Kongskilde’s pneumatic conveying system has resulted in a significant cost saving for us!

We estimate our ROI to be 14 months. We can now buy raw material in 25 kg bags instead of in bulk, which gives us a significant saving every time we purchase raw material.

Furthermore, we have achieved effectiveness in terms of time consumption when receiving raw material for our production.”